A high toughness enamel coating

A high-toughness, enamel technology, applied in the field of enamel coating, can solve the problems of affecting the service life of the enamel liner, cracks on the enamel body, and poor toughness of the enamel layer, so as to improve the resistance to thermal shock and water pressure. performance, improving toughness, and overcoming cracking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

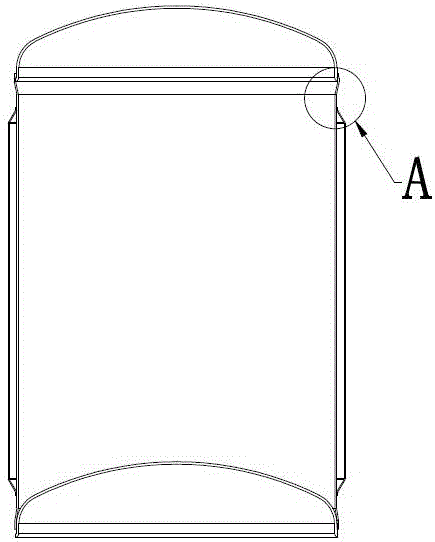

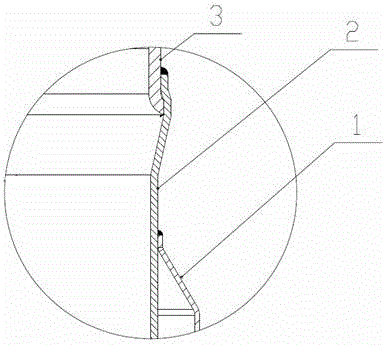

Image

Examples

Embodiment 1

[0035] A high-toughness enamel coating includes: a porcelain layer base material and an abrasive,

[0036] The mass ratio of the porcelain base material is as follows:

[0037] SiO 2 50

[0038] al 2 o 3 1.0

[0039] ZrO 2 5

[0040] TiO 2 2

[0041] B 2 o 3 10

[0042] Li 2 O 3

[0043] Na 2 O 15

[0044] CaF 2 2

[0045] Na 2 SiF 6 2

[0046] CoO 1.5

[0047] NiO 0.3

[0048] MnO 0.3;

[0049] The mass portion proportioning of described ground addition thing is as follows:

[0050] Glaze 100

[0051] Quartz sand 25

[0052] Nano Toughener 5

[0053] Magnesium carbonate 0.5

[0054] Borax pentahydrate 0.5

[0057] Among them, the nano-toughener includes 80 (wt)% nano-ZrO 2 and 20(wt)% nano-Al 2 o 3 , nano-ZrO 2 The crystal grain size is 25-55nm and the dispersion is very high, nano-Al 2 o 3 The crystal grain size is 50-200nm and has a porous structure.

[0058] The enamel co...

Embodiment 2

[0060] A high-toughness enamel coating resistant to high-temperature hot water corrosion includes: a porcelain layer base material and abrasives,

[0061] The mass ratio of the porcelain base material is as follows:

[0062] SiO 2 52

[0063] ZrO 2 8

[0064] TiO 2 5

[0065] B 2 o 3 12

[0066] Li 2 O 2

[0067] Na 2 O 14

[0068] CaF 2 2

[0069] Na2 SiF 6 3

[0070] CoO 1

[0071] NiO 0.2

[0072] MnO 0.4;

[0073] The mass portion proportioning of described ground addition thing is as follows:

[0074] Glaze 100

[0075] Quartz sand 22

[0076] Nano Toughener 7

[0077] Magnesium carbonate 0.8

[0078] Borax pentahydrate 0.3

[0080] Sodium nitrite 0.4,

[0081] Among them, the nano-toughener includes 80 (wt)% nano-ZrO 2 and 20(wt)% nano-Al 2 o 3 , nano-ZrO 2 The crystal grain size is 25-55nm and the dispersion is very high, nano-Al 2 o 3 The crystal grain size is 50-200nm and has a porous structure.

[0...

Embodiment 3

[0084] A high-toughness enamel coating resistant to high-temperature hot water corrosion includes: a porcelain layer base material and abrasives,

[0085] The mass ratio of the porcelain layer base material is as follows:

[0086] SiO 2 50

[0087] al 2 o 3 0.8

[0088] ZrO 2 3

[0089] TiO 2 4

[0090] B 2 o 3 10

[0091] Li 2 O 3

[0092] Na 2 O 16

[0093] CaF 2 4

[0094] Na 2 SiF 6 1

[0095] CoO 1.5

[0096] NiO 0.4

[0097] MnO 0.5;

[0098] The mass portion proportioning of described ground addition thing is as follows:

[0099] Glaze 100

[0100] Quartz sand 18

[0101] Nano Toughener 10

[0103] Borax pentahydrate 0.5

[0104] Sodium aluminate 0.3

[0105] Sodium nitrite 0.4,

[0106] Among them, the nano-toughener includes 80 (wt)% nano-ZrO 2 and 20(wt)% nano-Al 2 o 3 , nano-ZrO 2 The crystal grain size is 25-55nm and the dispersion is very high, nano-Al 2 o 3 The crystal grain size is 50-200n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com