Rapid prototyping equipment and method based on femtosecond laser and ion beam composite technology

A femtosecond laser and forming equipment technology, applied in the field of femtosecond laser and ion beam, can solve the problems of low intensity, spheroidization, powder blowing, etc., and achieve the effect of improving the control ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

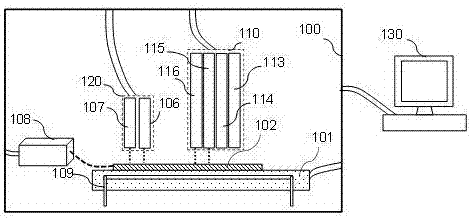

[0028] figure 1 It is a schematic diagram of the principle of the rapid prototyping manufacturing equipment of the present invention. The integrated rapid prototyping equipment mainly includes five parts: a vacuum chamber 100 , a workbench 101 , a feeding and laying device 108 , a rapid prototyping device 120 , and a real-time monitoring system 110 . The workbench 101 is provided with an internal liquid for cooling; the feeding and laying device 108 can be used to lay raw materials; the rapid prototyping device 120 is composed of an integrated fiber laser 107 and ion beam 106 equipment; the real-time monitoring system 110 includes A scanning electron microscope system 113 , a mass spectrometer 114 , an X-ray diffractometer 115 , and an infrared camera 116 . All devices are placed in the vacuum chamber 100 and connected with the control and display system 130 outside.

[0029] The multi-wavelength fiber laser is an integrated laser that integrates three short-pulse lasers: na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com