Sand making system and method using high frequency screen under strong wind conditions

A high-frequency sieve and condition technology, applied in chemical instruments and methods, sieves, solid separation, etc., can solve the problems of shortened effective running time, visibility can not meet the requirements of observation and maintenance, production stop, etc., to avoid occupational health hazards, The effect of increasing effective uptime and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

[0034] The sand field of a certain project department of the company was built in the tuyere of the canyon. The system was running with serious dust and low visibility during operation, resulting in inadequate operation observation, and it was impossible to carry out partial maintenance while production was running. Therefore, the maintenance time of the system is long, and the relative running time is short, so it is difficult to guarantee the aggregate supply.

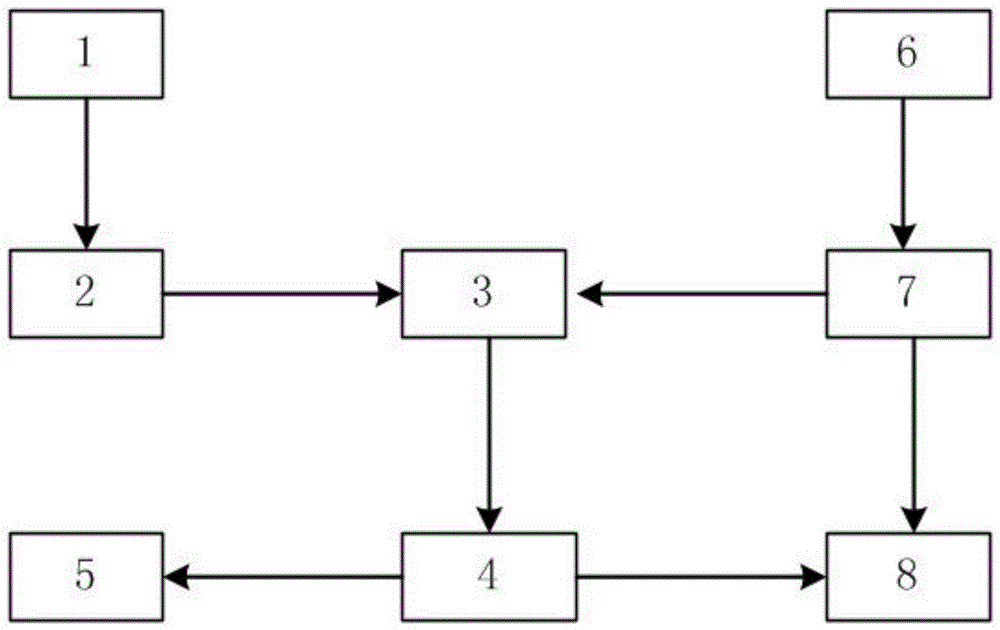

[0035] Therefore, through the efforts of a large number of developers, the design such as figure 1 A sand making system using high-frequency sieve under strong wind conditions is shown, including dewatering screen 1, sand powder recovery station 2, water tank 3, mud treatment device 4, finished product collection device 5, bean stone screen 6, sand powder rapid separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com