Automatic installation and effect detection device of solar cell module junction box cover

A solar cell and automatic installation technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as unbalanced pressing standards, unbalanced installation pressure, and poor component cracks, etc., to reduce The effects of secondary adverse effects, saving working hours, and avoiding occupational health hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

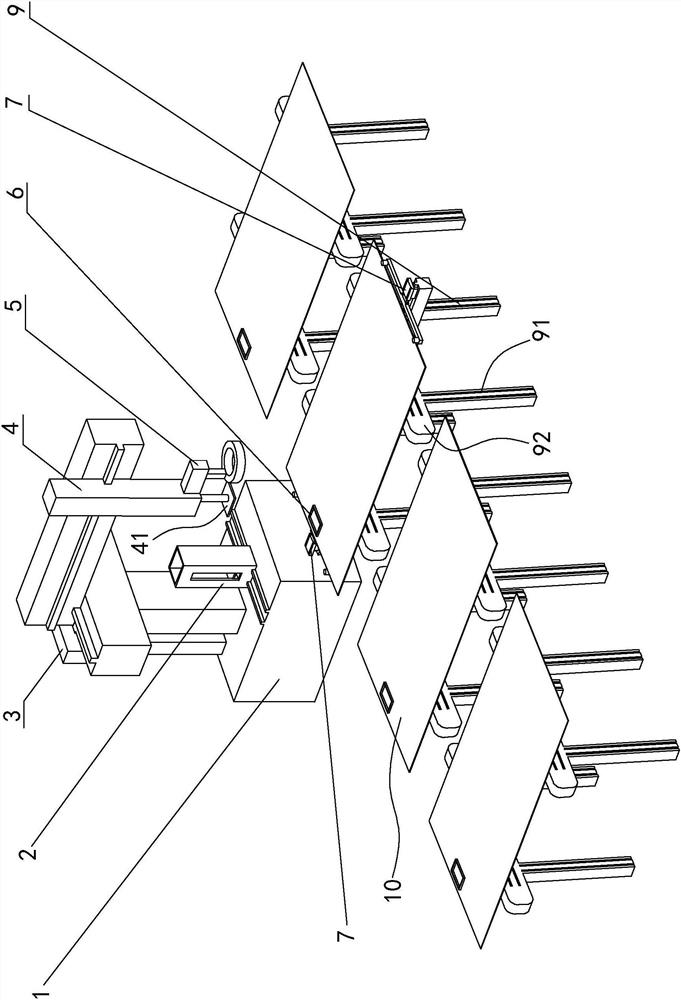

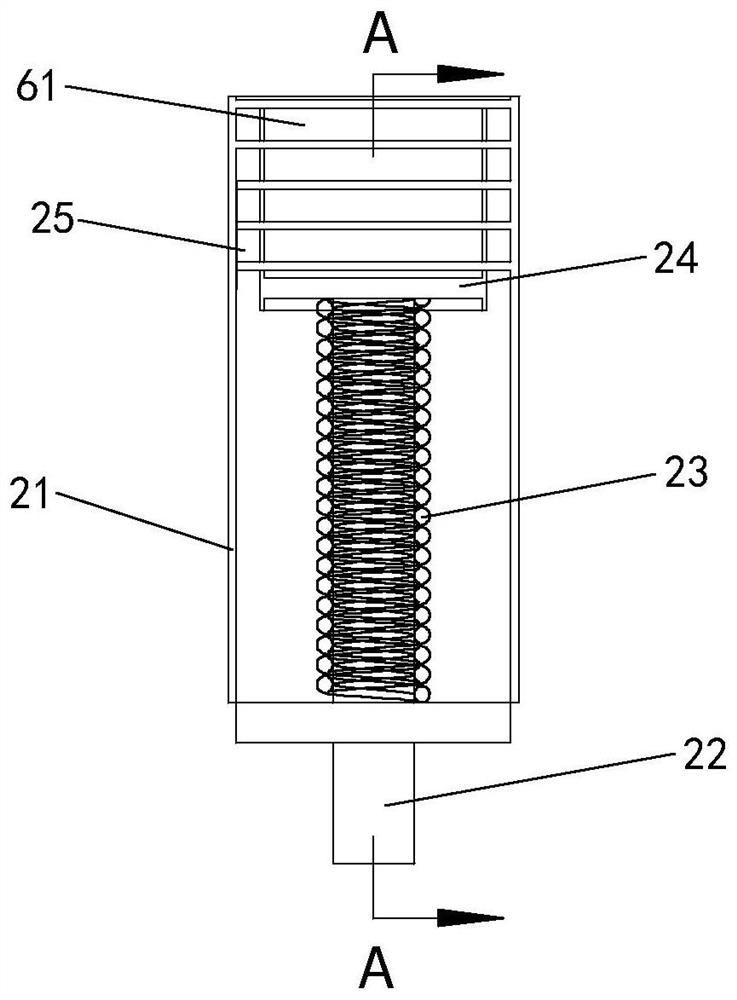

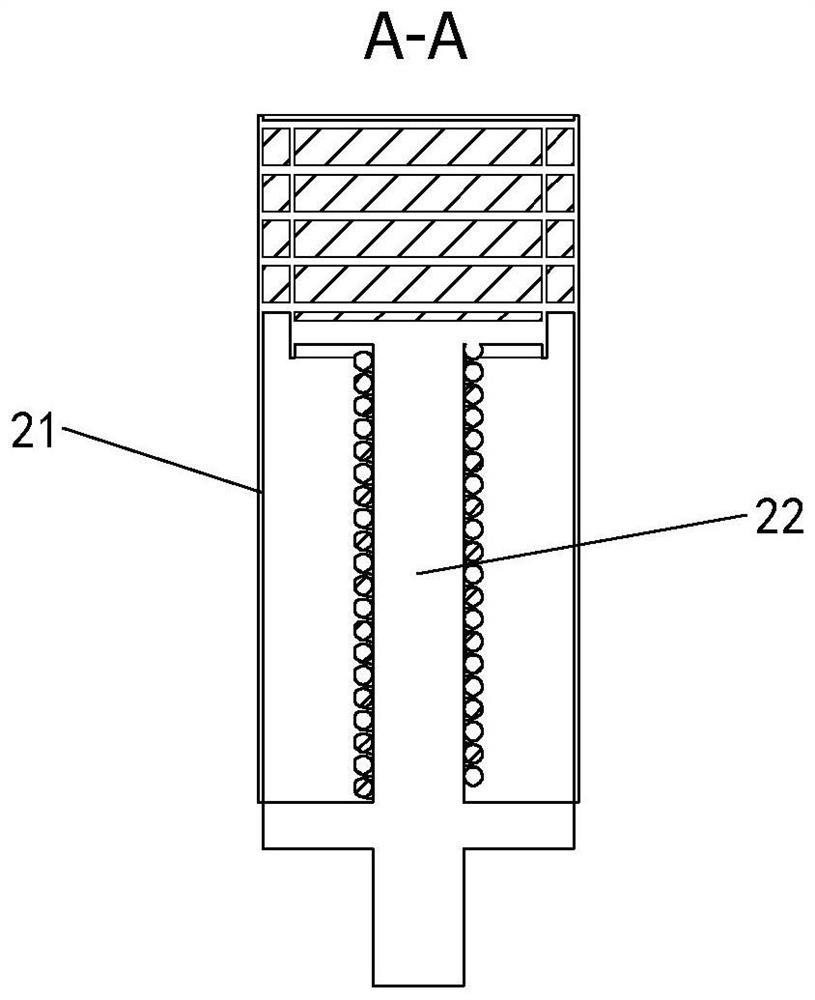

[0043] like Figure 1 to Figure 5 The automatic installation and effect detection device for the solar cell module junction box cover includes an automatic component transmission mechanism 9 and a component position positioning mechanism 7. The component automatic transmission mechanism 9 is used to transport the component 10, and the component position positioning mechanism 7 is installed on the component On the automatic transmission mechanism 9, it is used to position the assembly 10. The device also includes a lid delivery mechanism 2, a lid installation mechanism, a lid installation support mechanism 8, an effect detection mechanism 5 and a controller, and the lid delivery mechanism 2 For containing the box cover 61, the box cover installation mechanism is used to take out the box cover 61 contained in the box cover conveying mechanism 2 and install it on the junction box 6 of the solar cell module. The box cover installation mechanism includes a suction cup gripper 41 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com