Condensate pump frequency conversion decoupling control system and method for coal-fired power plant

A condensate pump and decoupling control technology, applied in the direction of controlling water supply, separation methods, chemical instruments and methods, etc., can solve the problems of reduced anti-disturbance and anti-interference ability, poor energy saving effect of condensate system, poor control stability, etc. Achieve the effect of reducing throttling loss and plant power consumption, realizing anti-disturbance and anti-interference ability, and ensuring reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

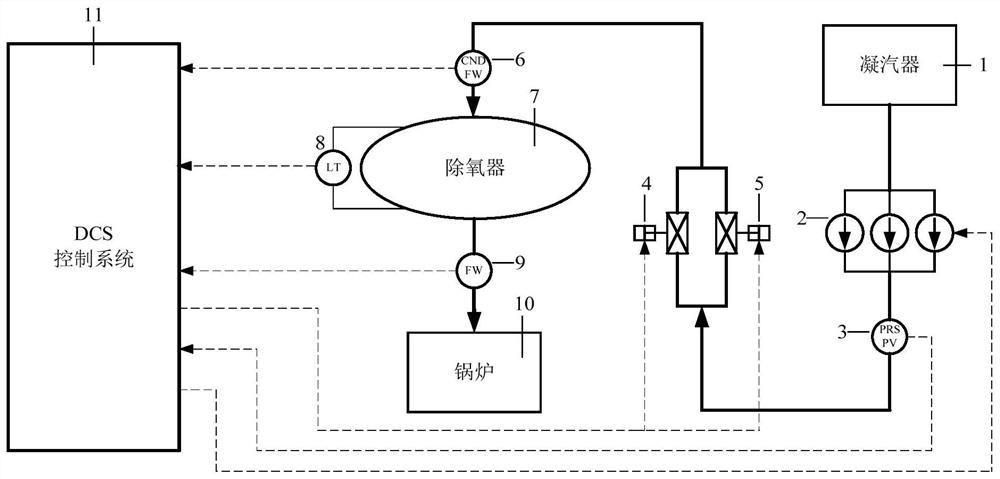

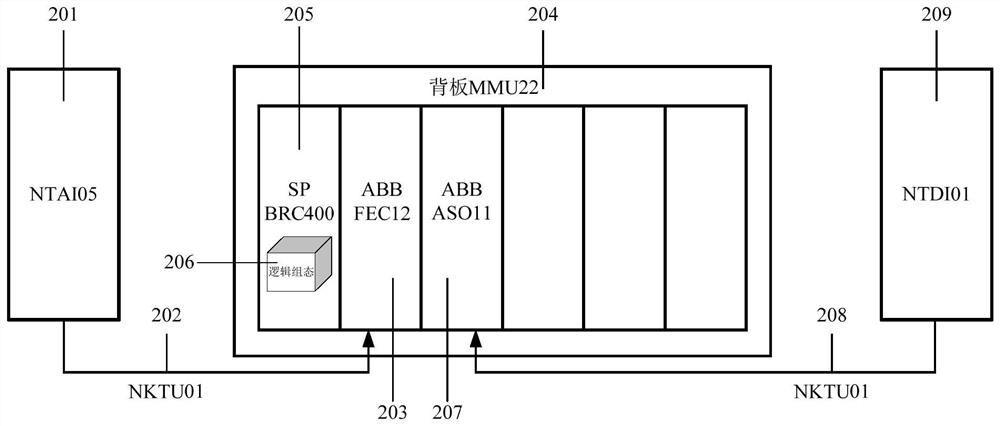

[0051] Such as Figure 1 to Figure 3 The shown system embodiment of the present invention includes sequentially connected by pipelines: a condenser 1 for condensing the exhaust steam of the steam turbine of the coal-fired power plant and recovering pure condensed water to provide boiler feed water, and for controlling its Three parallel-connected condensate pumps 2 with frequency converters for the final condensate pipe pressure and water level of the deaerator, and a pressure transmitter 3 installed on the outlet main pipe of the three condensate pumps 2 for measuring the pressure of the condensate pipe , parallel deaerator water level sub-regulating valve 4 and deaerator water level main regulating valve 5 with split-type intelligent single-acting positioner for controlling the water level of the deaerator and the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com