A method for extracting valuable metals from low-grade copper-lead-zinc-iron-iron polymetallic sulfide ores

A sulfide ore and polymetallic technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve problems such as poor adaptability, difficult operation, and adverse environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

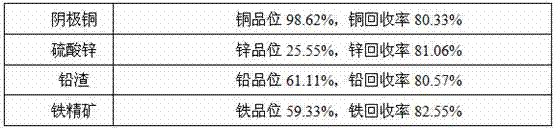

Embodiment 1

[0030] Copper-lead-zinc-iron polymetallic sulfide ore from Hanyuan area of Sichuan is used as raw material. The raw ore copper grade is 0.15%, lead grade is 1.08%, zinc grade is 0.88%, and iron grade is 22.64%.

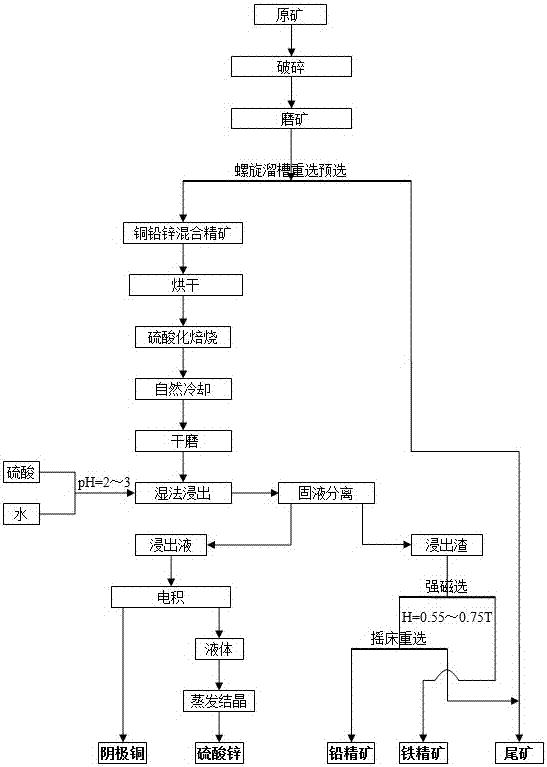

[0031] Such as figure 1 As shown, a method for processing low-grade copper-lead-zinc-iron-iron polymetallic sulfide ores to extract valuable metals comprises the following steps:

[0032] S1. Ore crushing and primary grinding stage: The raw material low-grade copper-lead-zinc-iron-iron polymetallic sulfide ore is crushed by a crusher to a particle size of less than 5mm, and then the sample with a particle size of less than 5mm is ground to a particle size by a rod mill. The mineral aggregates with a diameter of ≤0.154mm accounted for 85% of the total mineral aggregate weight;

[0033] S2, spiral chute re-election pre-selection stage: the ore obtained in step S1 is pre-selected by spiral chute re-election to obtain copper-lead-zinc-iron mixed concentrate;

[0034] ...

Embodiment 2

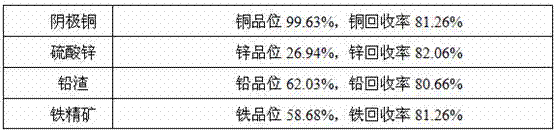

[0045]Copper-lead-zinc-iron polymetallic sulfide ore from Lanping, Yunnan Province is used as raw material. The ore copper grade is 0.18%, lead grade is 0.86%, zinc grade is 1.15%, and iron grade is 23.66%.

[0046] Such as figure 1 As shown, a method for processing low-grade copper-lead-zinc-iron-iron polymetallic sulfide ores to extract valuable metals comprises the following steps:

[0047] S1. Ore crushing and primary grinding stage: The raw material low-grade copper-lead-zinc-iron-iron polymetallic sulfide ore is crushed by a crusher to a particle size of less than 5mm, and then the sample with a particle size of less than 5mm is ground to a particle size by a rod mill. Mineral materials with a diameter of ≤0.154mm account for 80% of the total weight of mineral materials;

[0048] S2, spiral chute re-election pre-selection stage: the ore obtained in step S1 is pre-selected by spiral chute re-election to obtain copper-lead-zinc-iron mixed concentrate;

[0049] S3. Copper...

Embodiment 3

[0060] The copper-lead-zinc-iron polymetallic sulfide ore in Xishuangbanna, Yunnan Province is used as raw material. The ore copper grade is 0.22%, lead grade is 1.05%, zinc grade is 1.24%, and iron grade is 19.65%.

[0061] Such as figure 1 As shown, a method for processing low-grade copper-lead-zinc-iron-iron polymetallic sulfide ores to extract valuable metals comprises the following steps:

[0062] S1. Ore crushing and primary grinding stage: The raw material low-grade copper-lead-zinc-iron-iron polymetallic sulfide ore is crushed by a crusher to a particle size of less than 5mm, and then the sample with a particle size of less than 5mm is ground to a particle size by a rod mill. Mineral materials with a diameter of ≤0.154mm account for 90% of the total weight of mineral materials;

[0063] S2, spiral chute re-election pre-selection stage: the ore obtained in step S1 is pre-selected by spiral chute re-election to obtain copper-lead-zinc-iron mixed concentrate;

[0064] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com