Method for treating low-grade copper-lead-zinc-iron multi-metal sulfide ores to extract valuable metals

A technology of valuable metals and sulfide ores, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve problems such as poor adaptability, difficult operation, and adverse environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

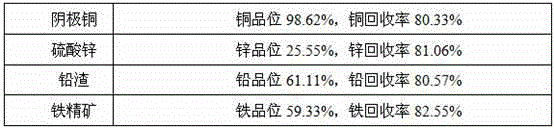

Embodiment 1

[0030] Using copper-lead-zinc-iron polymetallic sulfide ore from Hanyuan, Sichuan as raw materials, the raw ore copper grade is 0.15%, lead grade is 1.08%, zinc grade is 0.88%, and iron grade is 22.64%.

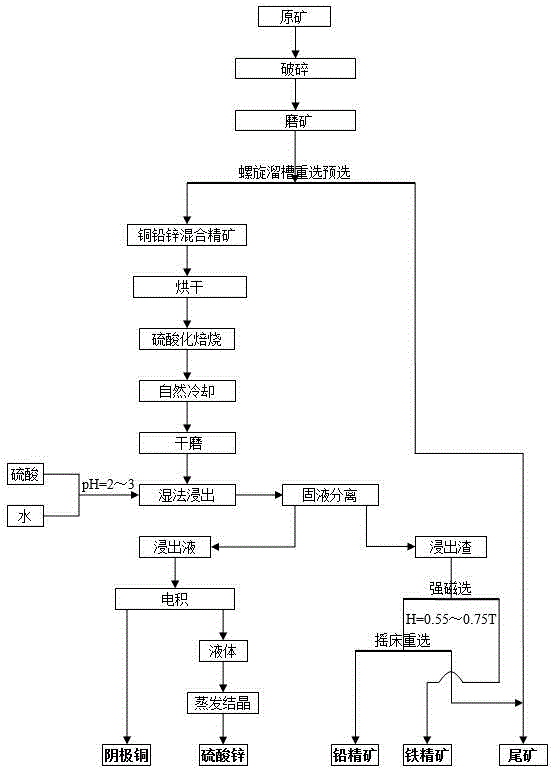

[0031] Such as figure 1 As shown, a method for processing low-grade copper-lead-zinc-iron polymetallic sulfide ore to extract valuable metals includes the following steps:

[0032] S1. Ore crushing and first-stage grinding stage: use a crusher to crush the raw material low-grade copper-lead-zinc-iron polymetallic sulfide ore to a particle size of 5mm or less, and then use a rod mill to grind the sample with a particle size of 5mm or less. The proportion of the mineral material with diameter ≤0.154mm to the total mineral material weight is 85%;

[0033] S2, spiral chute reselection and preselection stage: the mineral material obtained in step S1 is preselected by spiral chute reselection to obtain a mixed concentrate of copper, lead, zinc and iron;

[0034] S3. Drying stage of the cop...

Embodiment 2

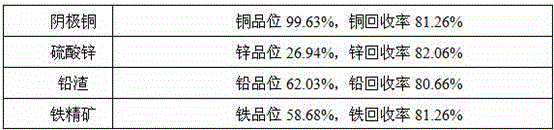

[0045] Using copper-lead-zinc-iron polymetallic sulfide ore from Lanping, Yunnan as raw materials, the raw ore copper grade is 0.18%, lead grade is 0.86%, zinc grade is 1.15%, and iron grade is 23.66%.

[0046] Such as figure 1 As shown, a method for processing low-grade copper-lead-zinc-iron polymetallic sulfide ore to extract valuable metals includes the following steps:

[0047] S1. Ore crushing and one-stage grinding stage: use a crusher to crush the low-grade copper-lead-zinc-iron polymetallic sulfide ore ore to a particle size below 5mm, and then use a rod mill to grind the sample with a particle size below 5mm to a particle size The proportion of the mineral material with diameter ≤0.154mm to the total mineral material weight is 80%;

[0048] S2, spiral chute reselection and preselection stage: the mineral material obtained in step S1 is preselected by spiral chute reselection to obtain a mixed concentrate of copper, lead, zinc and iron;

[0049] S3. Drying stage of the copper-...

Embodiment 3

[0060] The copper-lead-zinc-iron polymetallic sulfide ore in the Xishuangbanna area of Yunnan is used as raw material. The raw ore copper grade is 0.22%, lead grade is 1.05%, zinc grade is 1.24%, and iron grade is 19.65%.

[0061] Such as figure 1 As shown, a method for processing low-grade copper-lead-zinc-iron polymetallic sulfide ore to extract valuable metals includes the following steps:

[0062] S1. Ore crushing and one-stage grinding stage: use a crusher to crush the low-grade copper-lead-zinc-iron polymetallic sulfide ore ore to a particle size below 5mm, and then use a rod mill to grind the sample with a particle size below 5mm to a particle size The proportion of the mineral material with diameter ≤0.154mm to the total mineral material weight is 90%;

[0063] S2, spiral chute reselection and preselection stage: the mineral material obtained in step S1 is preselected by spiral chute reselection to obtain a mixed concentrate of copper, lead, zinc and iron;

[0064] S3. Dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com