Magnetic filtration and separation device

A separation device and magnetic filtration technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of slow response to magnetic field induction, large magnetic energy consumption of electromagnetic coils, uneven distribution of permanent magnet magnetic field, etc., to achieve Enhanced adsorption separation and filterability, uniform magnetic force distribution, and the effect of innovative design goals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation

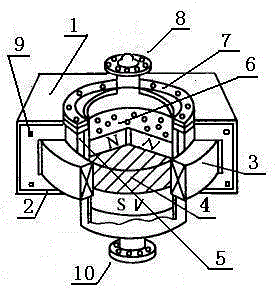

[0024] A magnetic filtering and separating device, composed of a magnetic field regulator 1, a magnetic resistance sheet 2, a magnetic quantum generator 3, a magnetic rotating net 6, a pressure magnetic ring 7, a liquid outlet 8, a positioning pin hole 9, and a liquid inlet 10 , the magnetic quantum generator 3 is inserted in the concave box nest of the magnetic field adjuster 1, the magnetic resistance sheet 2 is fixedly embedded in the four corner positioning holes of the semicircle concave section of the magnetic field adjuster 1 according to the positioning pin hole 9, and the magnetic rotation net 6 It is fixed on the magnetic drum 5 by the pressure magnetic ring 7.

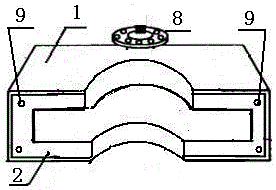

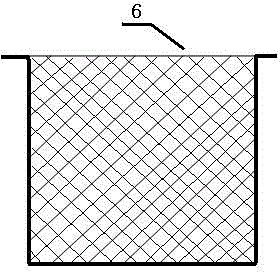

[0025] A liquid outlet 8 and a liquid inlet 10 are installed on the top and bottom of the magnetic drum 5, which are fixed by a magnetic pressure ring 7 with screws. 6. Fold the edge of the circumference of 60mm outwards, (see attached figure 2 , 3 ).

[0026] The material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com