Flat product made of metal material, in particular a steel material, use of such a flat product, and roll and method for producing such flat products

A technology of metal materials and flat plates, applied in metal rolling, metal rolling, metal processing, etc., can solve the problem that the accumulation of roll materials cannot be completely eliminated, and achieve the effects of low friction coefficient, high stability, and low wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] According to the invention, a surface texture with a deterministic distribution of design features (texture features) is produced using a rolling texture method using a pulsed laser, preferably a short-pulse or ultrashort-pulse laser, from a rotating roll remove material from the surface.

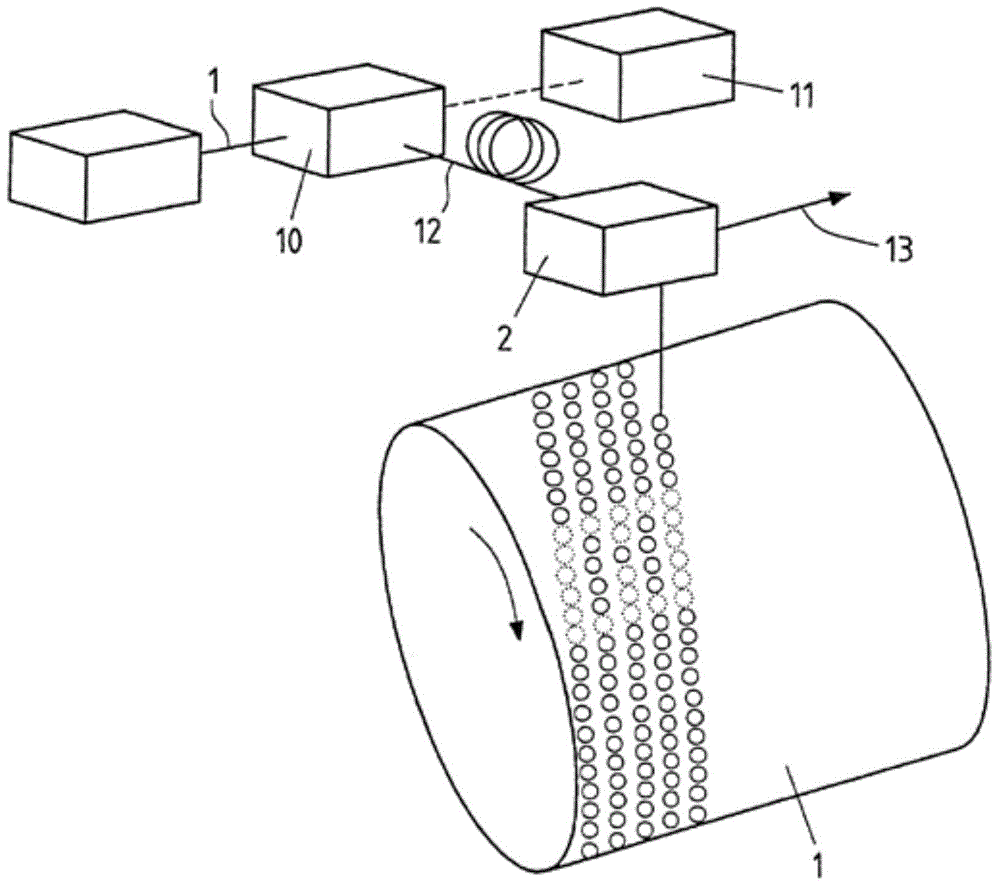

[0045] For this purpose, the roll 1 to be scored is rotated in a rotating device. While the roller is rapidly rotating, the converging optical device 2 that converges the laser beam onto the surface of the roller moves laterally in the direction of the roller axis at a relatively low speed. Thus, the laser beam traces a helical path on the roll surface ( figure 1 ).

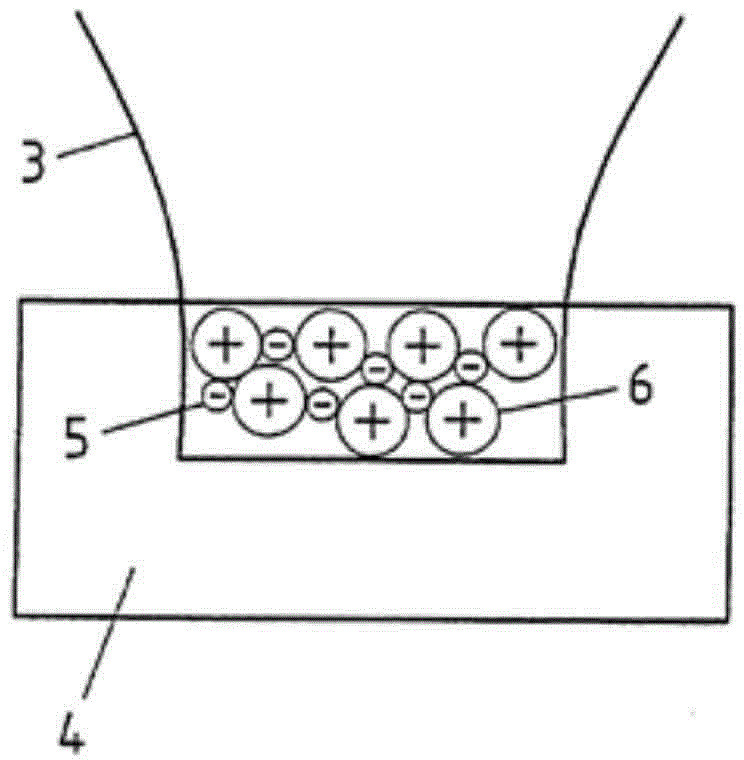

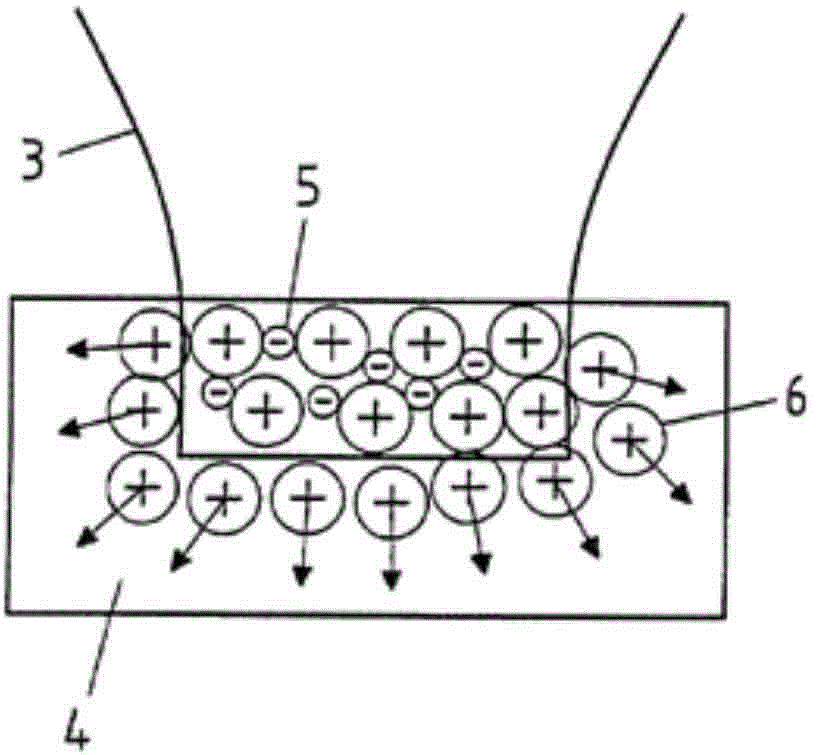

[0046] During a pulse duration of approximately 1 microsecond, the laser beam 3 penetrates to a certain depth into the material of the roller 1 . The material 4 or surface material of the roller 1 is composed of free conduction band electrons 5 and positive metal ions 6 ( figure 2 ).

[0047] The electrons 5 are a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com