Trench gate type igbt device and manufacturing method thereof

A manufacturing method and trench gate technology, which are applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of difficult driving, increased input capacitance, poor robust performance, etc., and achieve enhanced robustness, The effect of reducing input capacitance and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

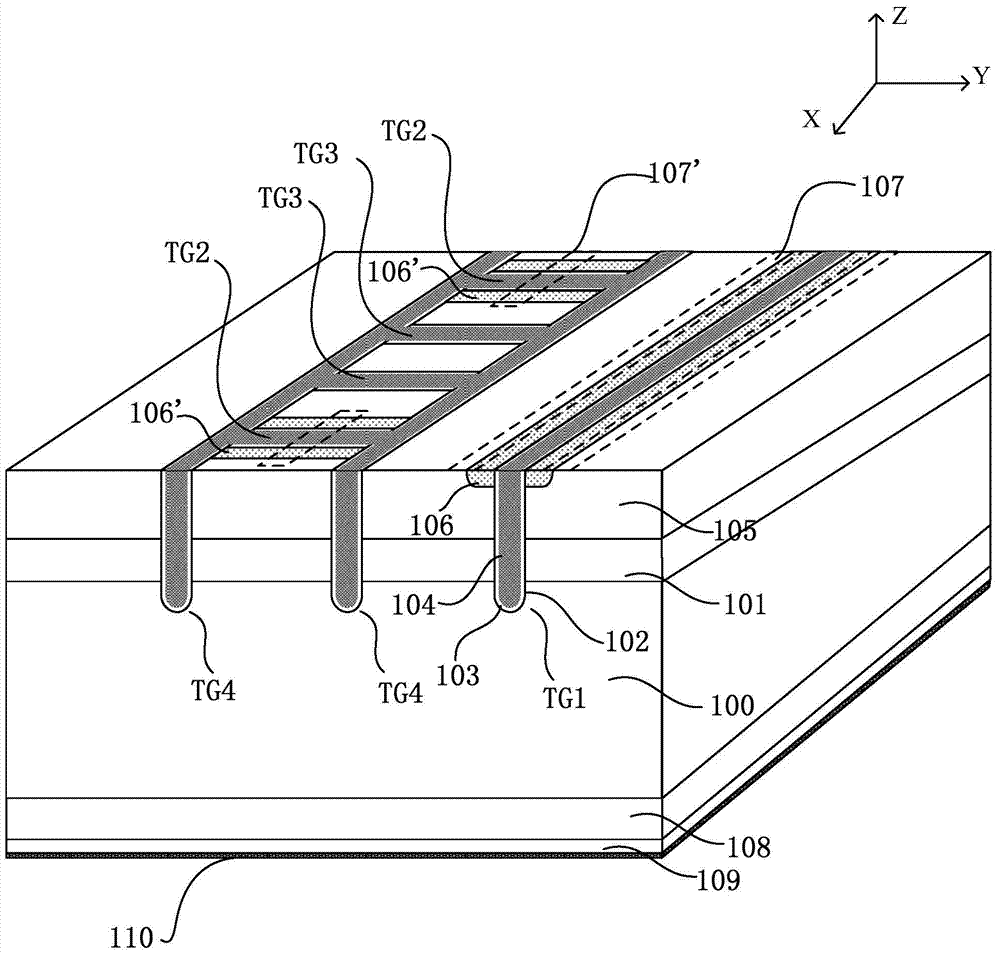

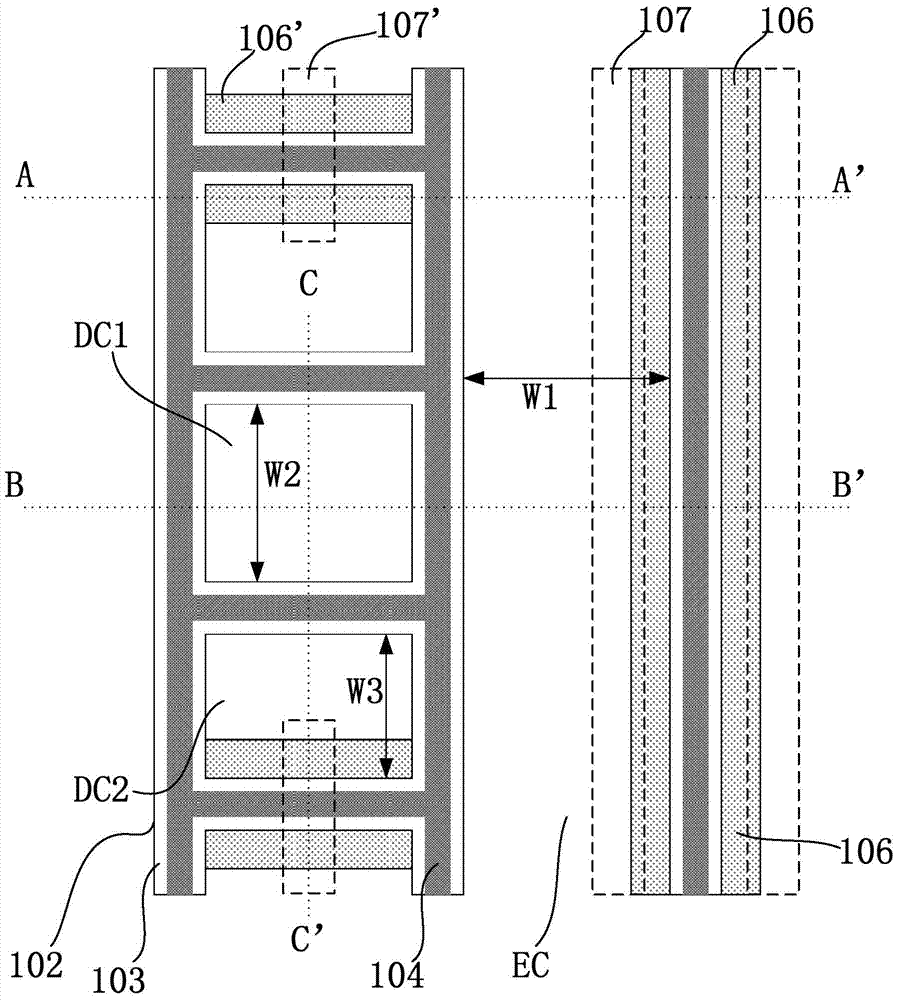

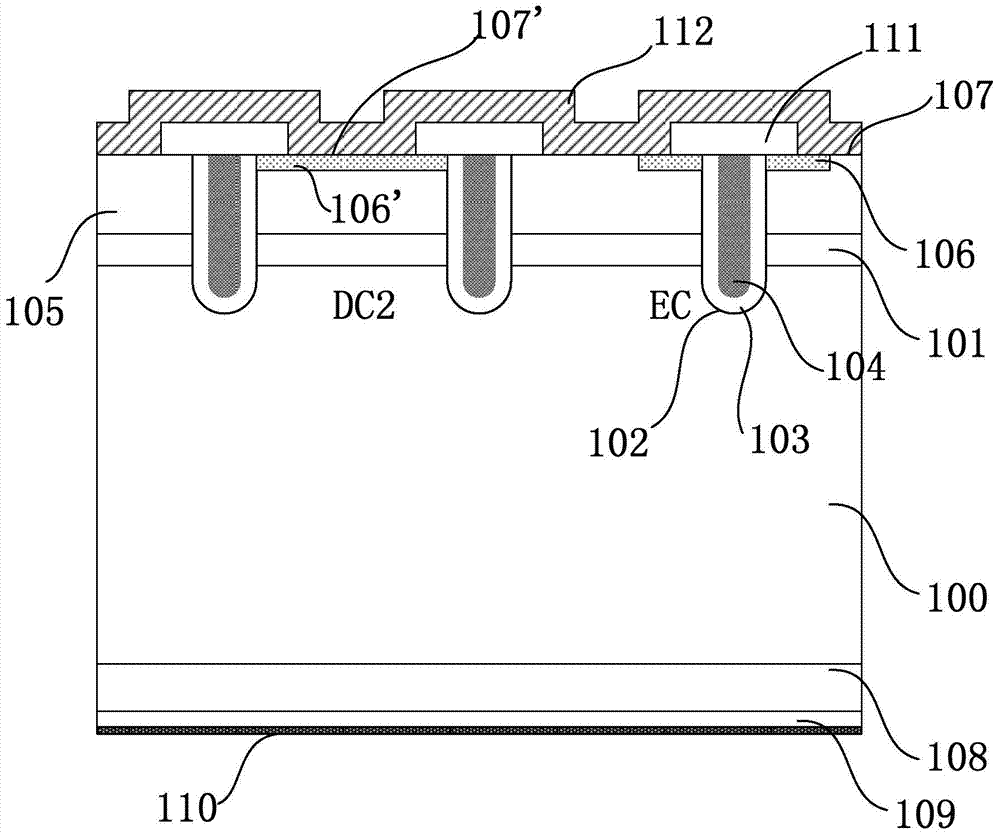

[0077] refer to Figure 1 to Figure 5 , the trench gate IGBT device of this embodiment mainly includes: drift region 100, buffer region 108, collector region 109, collector electrode 110, JFET doped region 101, base region 105, emitter region 106, quasi-emitter region 106' , a first trench gate structure TG1 , a second trench gate structure TG2 , a third trench gate structure TG3 , a fourth trench gate structure TG4 , a dielectric layer 111 and an emitter electrode 112 .

[0078] Further, the doping type of the drift region 100 is N type. The drift region 100 has opposite front and back surfaces, which are parallel to the XY plane.

[0079] The buffer zone 108 is located at the back of the drift region 100 , and the doping type of the buffer zone 108 is N type. Pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com