Pd-SnO2 oxide semiconductor sensor for carbon monoxide as well as preparation and application

An oxide semiconductor, carbon monoxide technology, applied in the direction of material resistance, can solve the problems of high detection lower limit and low sensitivity of sensors, and achieve the effect of low detection lower limit, high sensitivity, good selectivity and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

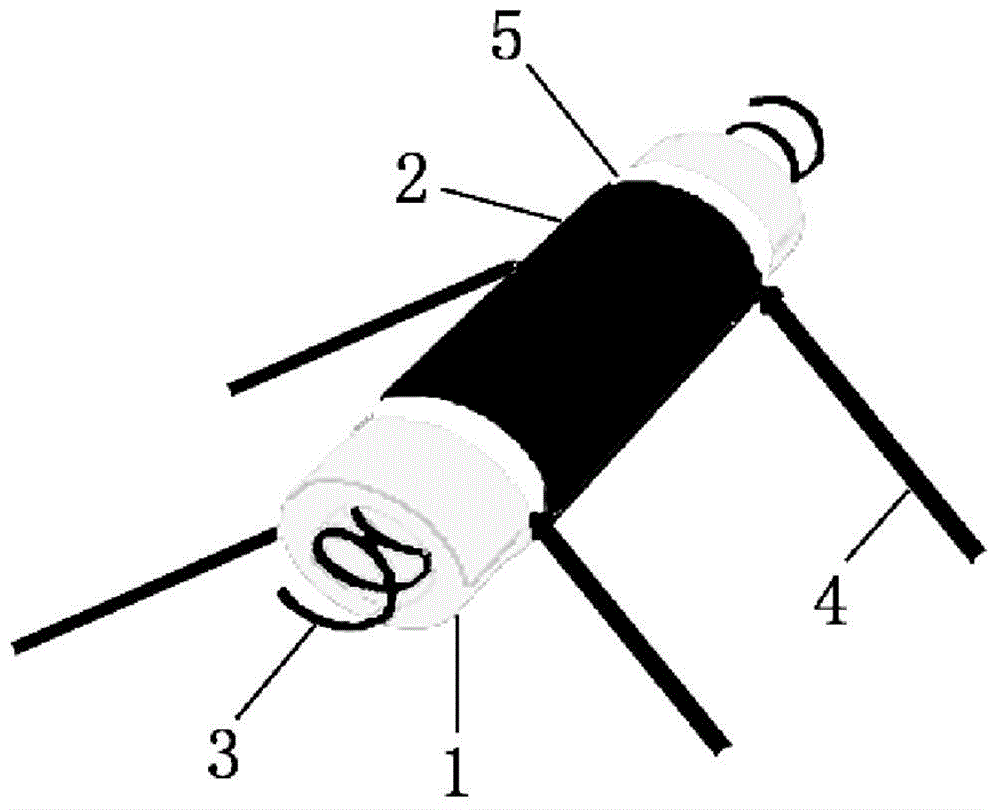

Image

Examples

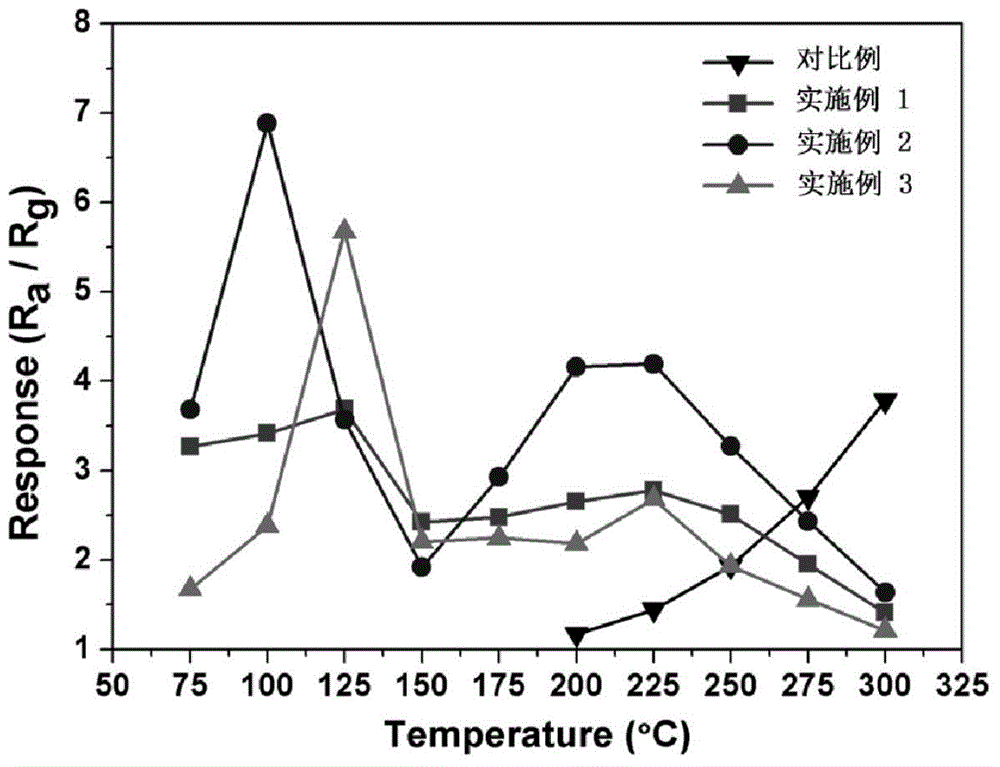

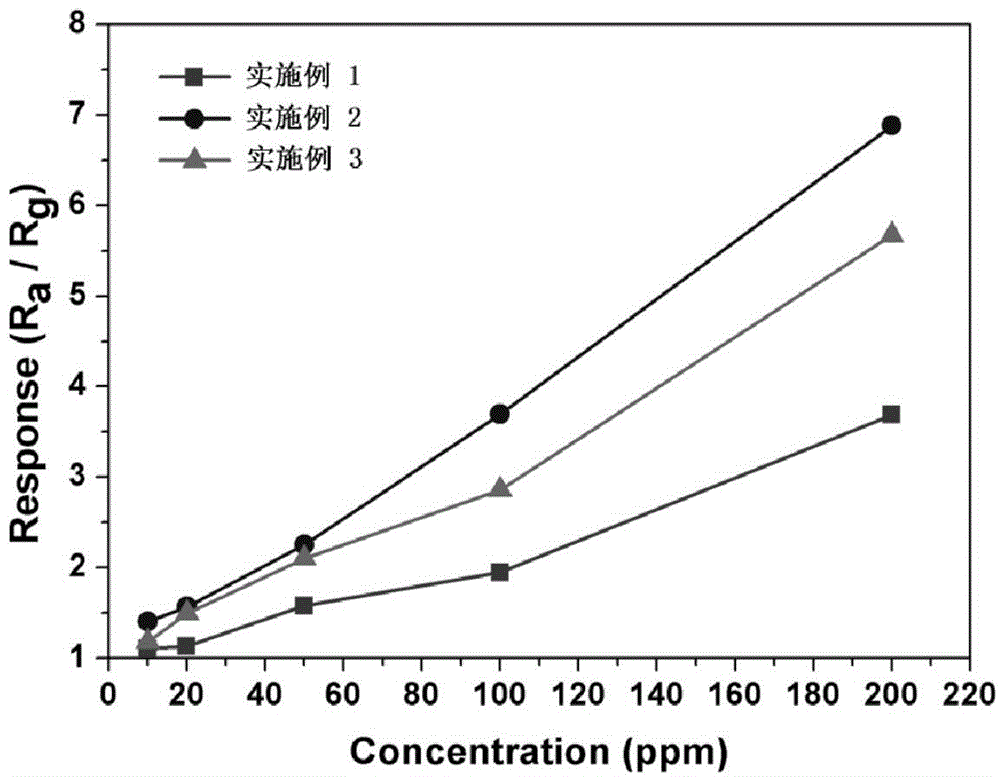

Embodiment 1

[0039] Pd-SnO with a mass ratio of element Pd / Sn in the reactant of 0.015:1 2 Oxide semiconductors are used as sensitive materials to make carbon monoxide sensors. The manufacturing process is

[0040] (1) First, 0.0125g PdCl 2 and a certain amount of ethylenediamine to configure 2ml of aqueous solution.

[0041] (2) 0.9g SnCl 2 .2H 2 O, 2.94g Na 3 C 6 h 5 o 7 .2H 2 Dissolve in 10ml of water while stirring, add 2ml of the aqueous solution in (1) and continue to stir to form a homogeneous solution, then add 10ml of 0.2M NaOH aqueous solution dropwise and then stir for 5 minutes;

[0042] (3) Put the mixed solution of (2) into a 100ml polytetrafluoroethylene kettle and seal it, put it into a microwave hydrothermal system, and set the microwave parameters as follows: the maximum power is 300W, first heat it to 180°C for 10 minutes, and keep the temperature at 180°C for one hour. After the end, the temperature was naturally lowered to room temperature, and the sample was ...

Embodiment 2

[0046] Pd-SnO with a mass ratio of element Pd / Sn in the reactant of 0.030:1 2 Oxide semiconductors are used as sensitive materials to make carbon monoxide sensors. The manufacturing process is

[0047] (1) First, 0.025g PdCl 2 and a certain amount of ethylenediamine to configure 2ml of aqueous solution.

[0048] (2) 0.9g SnCl 2 .2H 2 O, 2.94g Na 3 C 6 h 5 o 7 .2H 2 Dissolve in 10ml of water while stirring, add 2ml of the aqueous solution in (1) and continue to stir to form a homogeneous solution, then add 10ml of 0.2M NaOH aqueous solution dropwise and then stir for 5 minutes;

[0049] (3) Put the mixed solution of (2) into a 100ml polytetrafluoroethylene kettle and seal it, put it into a microwave hydrothermal system, and set the microwave parameters as follows: the maximum power is 300W, first heat it to 180°C for 10 minutes, and keep the temperature at 180°C for one hour. After the end, the temperature was naturally lowered to room temperature, and the sample was c...

Embodiment 3

[0053] Pd-SnO with a mass ratio of element Pd / Sn in the reactant of 0.045:1 2 Oxide semiconductors are used as sensitive materials to make carbon monoxide sensors. The manufacturing process is

[0054] (1) First, 0.0375g PdCl 2 and a certain amount of ethylenediamine to configure 2ml of aqueous solution.

[0055] (2) 0.9g SnCl 2 .2H 2 O, 2.94g Na 3 C 6 h 5 o 7 .2H 2 Dissolve in 10ml of water while stirring, add 2ml of the aqueous solution in (1) and continue to stir to form a homogeneous solution, then add 10ml of 0.2M NaOH aqueous solution dropwise and then stir for 5 minutes;

[0056] (3) Put the mixed solution of (2) into a 100ml polytetrafluoroethylene kettle and seal it, put it into a microwave hydrothermal system, and set the microwave parameters as follows: the maximum power is 300W, first heat it to 180°C for 10 minutes, and keep the temperature at 180°C for one hour. After the end, the temperature was naturally lowered to room temperature, and the sample was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com