Chrysophenine G production process

A production process and direct technology, applied in the field of production process of direct frozen yellow G, can solve the problems of production efficiency affecting the ecological environment, high cost, high energy consumption, unfavorable long-term production, etc., and achieve good color retention and durability, recycling Easy, cost-effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

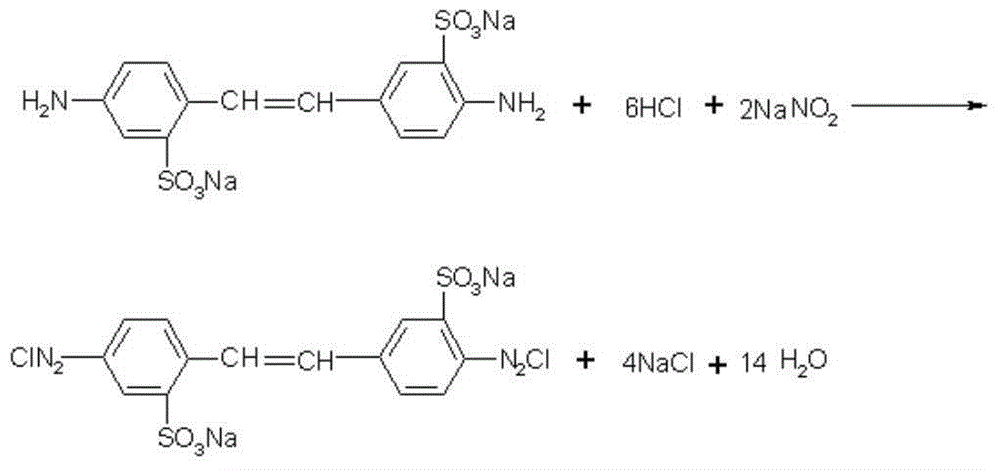

[0032] Step 1: DSD acid beating and diazotization

[0033] Rinse the diazonium tank, put in deionized water, put in sodium carbonate after heating, slowly put in the DSD acid paste during the stirring process, continue to heat up to 60°C after the feeding, pH value 7-8, and brown Clarify the liquid, then naturally cool to 45℃ under stirring, slowly add dilute hydrochloric acid for acidification, the acidification time is 2-2.5h, and then continue to stir for 4h, cool to below 30℃, add sodium nitrite solution within 1h for reconstitution Nitriding, then put it into the coupling tank and continue to stir and react for 3h to obtain the diazonium compound solution;

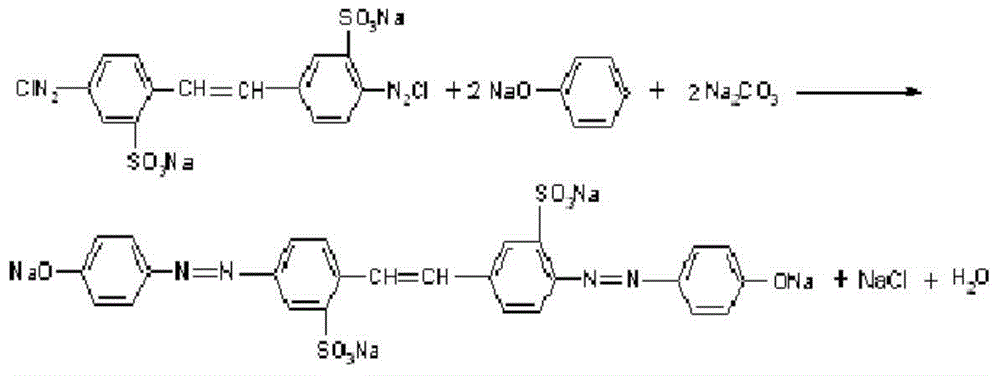

[0034] Step 2: Preparation of sodium phenate

[0035] Add deionized water to the phenol tank, add sodium carbonate and raise the temperature to 30°C, then add phenol, and stir to obtain sodium phenolate;

[0036] Step 3: Coupling

[0037] Add sodium sulfate to the diazonium compound solution obtained in step 1, and then quick...

Embodiment 2

[0044] The basic preparation process is adopted from Example 1, except that the molar ratio of DSD acid to sodium carbonate and sodium nitrite in step 1 is 1:3:7, and the molar ratio of diazonium compound solution to sodium phenolate in step 3 It is 1:6, and the reaction time of ethylation in step 4 is 20h.

Embodiment 3

[0046] The basic preparation process is adopted from Example 1, except that the molar ratio of DSD acid to sodium carbonate and sodium nitrite in step 1 is 1:2.5:6, and the molar ratio of diazonium compound solution to sodium phenolate in step 3 It is 1:5, and the reaction time of ethylation in step 4 is 19h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com