Graphene material and preparation method of electrode material of graphene material

A graphene and porous graphene technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as halide-intercalated graphene, and achieve excellent cycle stability, improved integrity, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Using ferric chloride as the intercalation agent and 300 mesh flake graphene as the precursor, the first-order graphite intercalation compound was prepared by the molten salt intercalation method. Add 100 mg of graphite intercalation compound with ferric chloride as intercalation agent into 100 mL of N,N-dimethylformamide solvent, break the cells in an ice bath and sonicate for 6 hours to obtain a graphene suspension. Filter the graphene suspension with a 0.2-micron organic filter membrane, wash with ethanol, and then add deionized water to wash after suction filtration. The slurry after suction filtration is freeze-dried to obtain graphene with a yield of about 95%. .

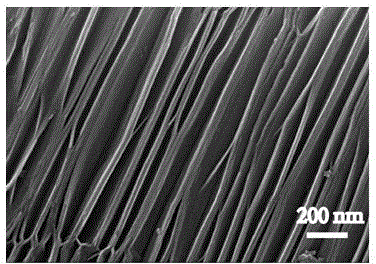

[0039] Such as figure 1 As shown, in Example 1, the graphite intercalation compound after intercalation is uniformly intercalated with an intercalation agent to form an accordion-like loose structure, which is easy for subsequent peeling off.

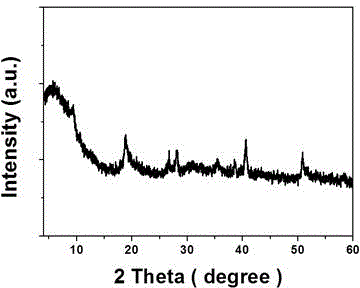

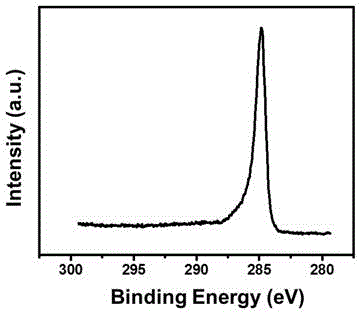

[0040] Such as figure 2 As shown, in Example 1, after t...

Embodiment 2

[0043] Using ferric chloride as the intercalation agent and 300 mesh flake graphene as the precursor, the first-order graphite intercalation compound was prepared by the molten salt intercalation method. Add 100 mg of graphite intercalation compound with ferric chloride as the intercalation agent to 100 mL of N, N-dimethylformamide solvent, break the cells in an ice bath and sonicate for 1 hour to obtain ferric chloride intercalated porous graphene suspension . Filter the graphene suspension with a 0.2-micron organic filter membrane, wash with ethanol, and then add deionized water to wash after suction filtration. The slurry after suction filtration is freeze-dried to obtain graphene with a yield of about 90%. .

[0044] Such as Figure 4 As shown, in Example 2, the black spots in the figure are ferric chloride, indicating that ferric chloride is stable and evenly distributed between the graphite layers.

[0045] Such as Figure 5 As shown, in Example 2, the ferric chlorid...

Embodiment 3

[0047] Using ferric chloride as the intercalation agent and 300-mesh flake graphene as the precursor, the second-order graphite intercalation compound was prepared by the molten salt intercalation method. Add 100 mg of graphite intercalation compound with ferric chloride as intercalation agent into 100 mL of N,N-dimethylformamide solvent, break the cells in an ice bath and sonicate for 3 hours to obtain a graphene suspension. The suspension of graphene is filtered with a 0.2 micron organic filter membrane, and washed with ethanol. After suction filtration, deionized water is added to clean, and the slurry after suction filtration is freeze-dried to obtain two-layer graphene with a yield of 95%. %about.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com