Central tube type ADSS (All-Dielectric Self-Supporting) optical fiber cable take-up machine

A central tube type and wire take-up technology, which is used in the transportation of filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of looping, increase the damage and breakage of the optical fiber, and reduce the surge of the optical cable. Small movement error, improved wire take-up efficiency, and orderly connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

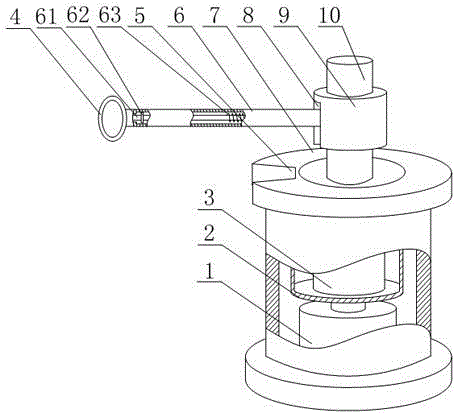

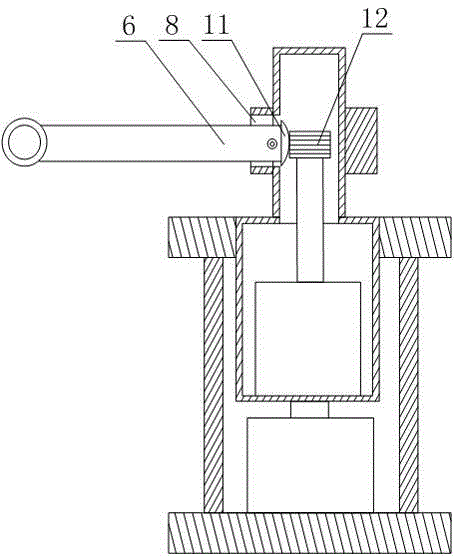

[0021] Such as figure 1 and figure 2 As shown, this embodiment includes a hollow cable reel 7 and a motor 1 fixed in the cable reel 7, the output end of the motor 1 is connected with a positioning cylinder 2, the upper end of the positioning cylinder 2 penetrates the upper end surface of the cable reel 7, and A cylinder 3 is installed in the positioning cylinder 2, and a rotating cylinder 10 communicating with it is fixed on the upper end surface of the positioning cylinder 2. The side wall of the rotating cylinder 10 is provided with a rectangular gap, and is hinged in the gap. There is a guide rod 6, and a plurality of ring teeth 12 are arranged on the output end of the cylinder 3. One end of the guide rod 6 is provided with a fan-shaped tooth 11 that matches the ring teeth 12, and the inside of the guide rod 6 is provided with a cavity. The end of the rod 61 is connected to the inner wall of the cavity by a spring 63, the movable end of the push rod 61 runs through the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com