Temperature Adjusting Device And Method Used For Battery Cell And Battery Module, Battery Unit, Battery And Battery System

A battery cell and temperature regulating device technology, applied in battery/battery traction, battery pack components, batteries, etc., can solve problems such as the inability of battery cells to reach lifespan, reduce the formation of condensed water, achieve temperature distribution, The effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

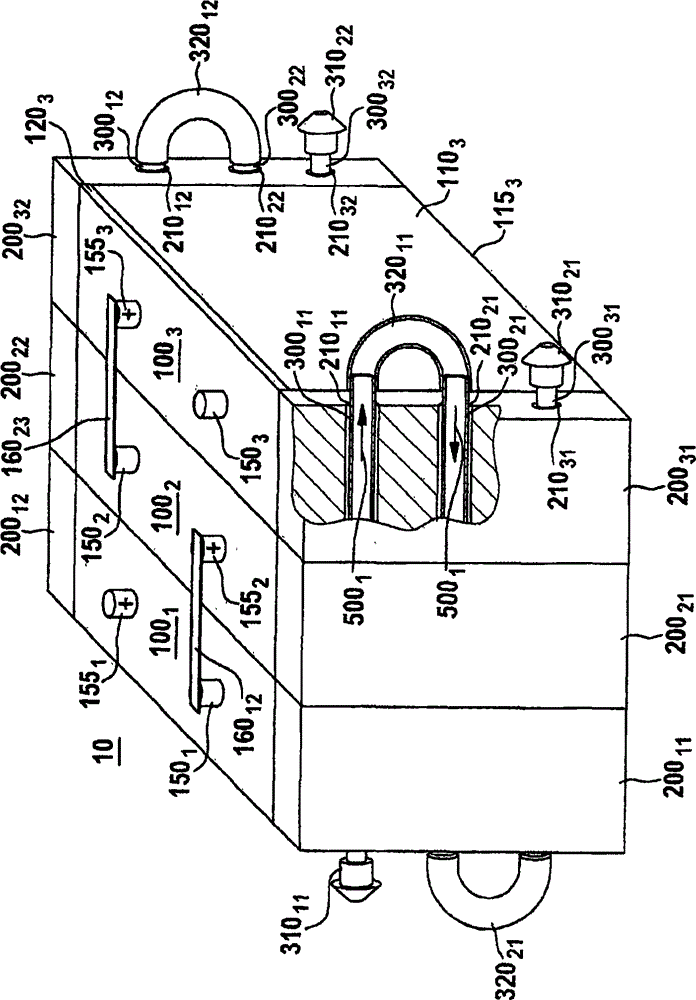

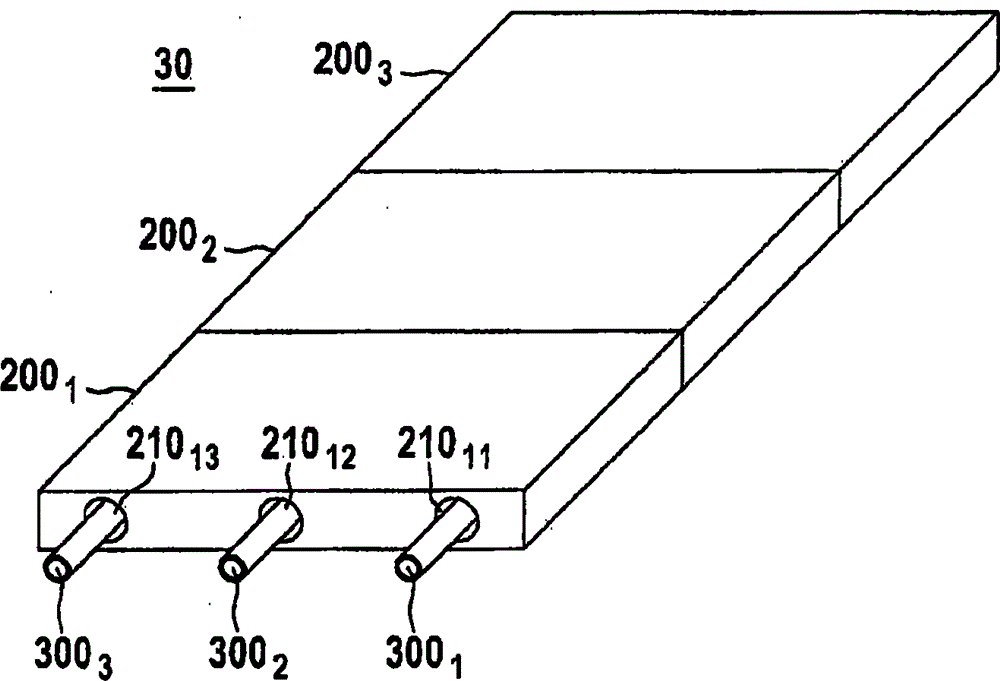

[0052] figure 1 Shown is a schematic perspective view of a battery module 10 according to one embodiment of the invention.

[0053] The battery module 10 includes a plurality of battery cells 100, namely 100 1 ...100 3 , such as two, three, four or more battery cells. Such as figure 1 Shown exemplarily in , the battery cell 100, 100 1 ...100 3 They are oriented in a first spatial direction, so that their longitudinal sides run parallel to one another, which are oriented in a second spatial direction perpendicular to the first spatial direction. In the case of intended use, a third spatial direction perpendicular to the first spatial direction and the second spatial direction is referred to as a battery cell 100 , 100 1 ...100 3 height direction.

[0054] Accordingly, a battery pack, battery or battery system may include a plurality of battery modules.

[0055] Battery cell 100, 100 1 ...100 3 Can be prismatic, such as square, and include a single cell housing 110 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com