Polyethylene valve sealing performance room temperature low pressure test method

A valve sealing and test method technology, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and decrease rate of fluid, can solve the problems of high cost, low efficiency, and long test period, and achieve a balance of reduction time, reduce test time, and shorten the effect of the transition process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

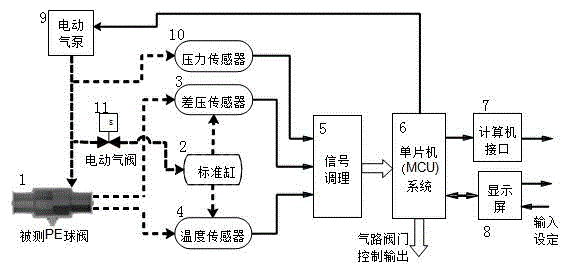

[0018] according to figure 1 As shown, the single-chip microcomputer system uses the electric air pump (9) to simultaneously pressurize the valve (1) test chamber and the standard cylinder (2) according to the given pressure requirements of the test. After the pressure sensor (10) obtains the actual pressure value of the compression, the single-chip microcomputer system The difference between it and the given pressure, under the control of a specific pressurization algorithm, realizes rapid pressurization of the cavity of the valve (1). This pressurization of the gas in the valve (1) test chamber and the standard cylinder (2) on the basis of atmospheric pressure may be accompanied by a slight temperature rise of the gas.

[0019] After the pressurization is completed, the electric gas valve (11) immediately cuts off the air channel between the tested valve (1) and the standard cylinder (2), and the differential pressure sensor (3) and temperature sensor (4) start to collect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com