Ultra-low temperature economizer for double reheat unit

A secondary reheating and ultra-low temperature technology, applied in feed water heaters, preheating, reducing greenhouse gases, etc., can solve the problems of increasing exergy loss in the condensate reheating process, and achieve the effect of reducing losses and reducing coal consumption for power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

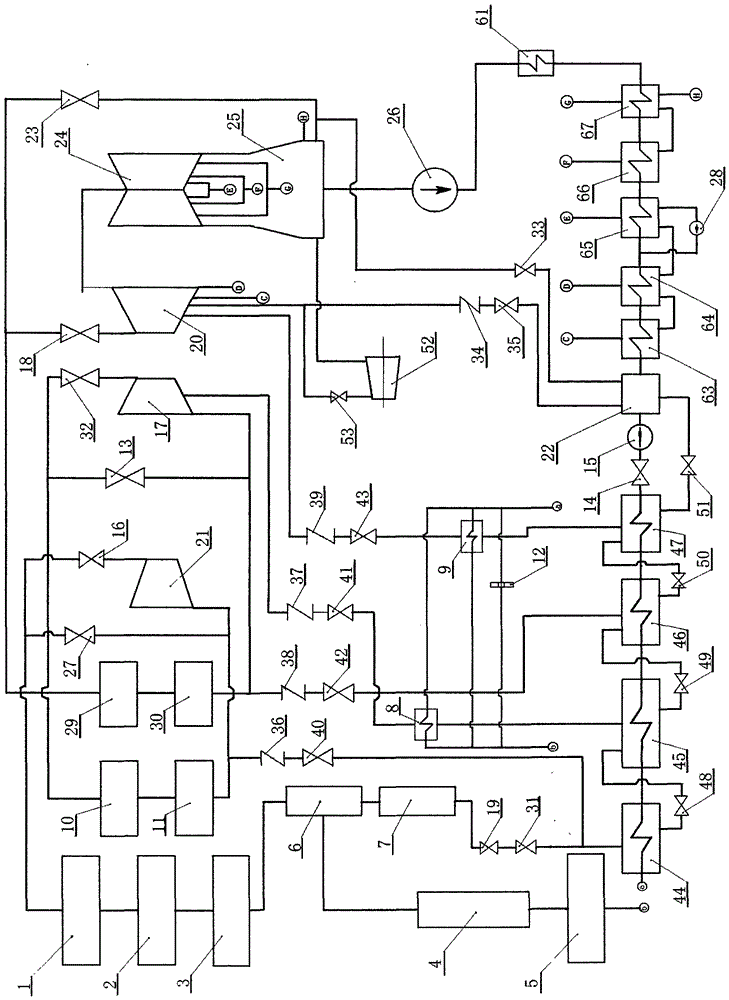

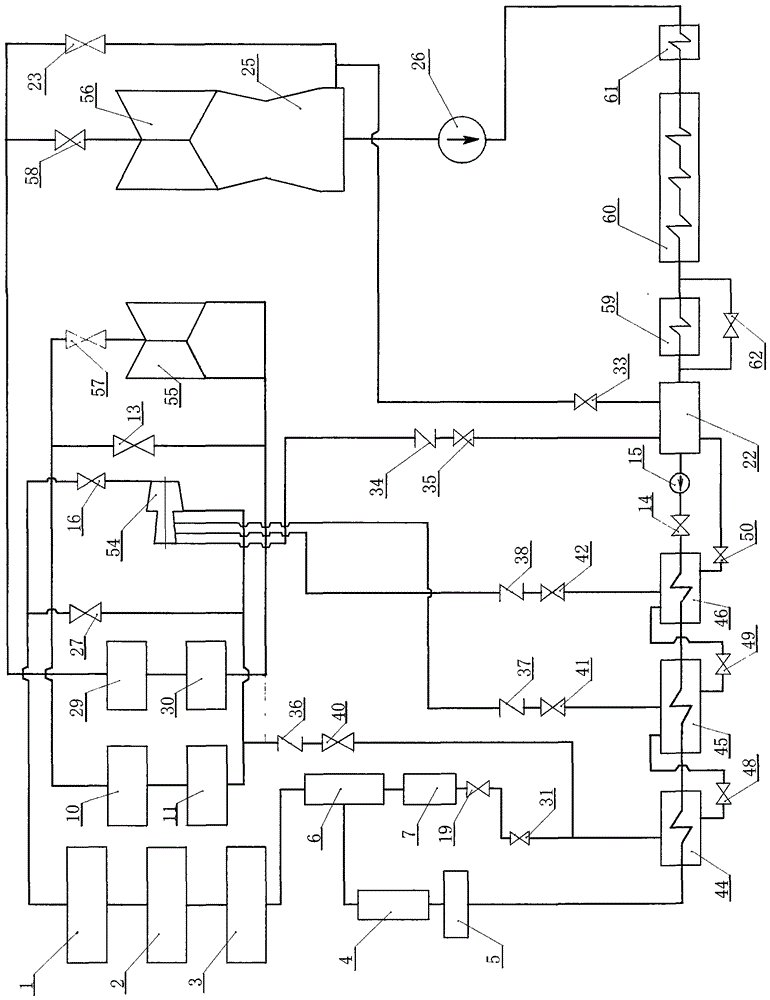

[0062] Combine now image 3 , Figure 4 The optimal way to realize the invention is illustrated by taking an ultra-low temperature economizer configured on a 1000MW level double reheating unit as an example.

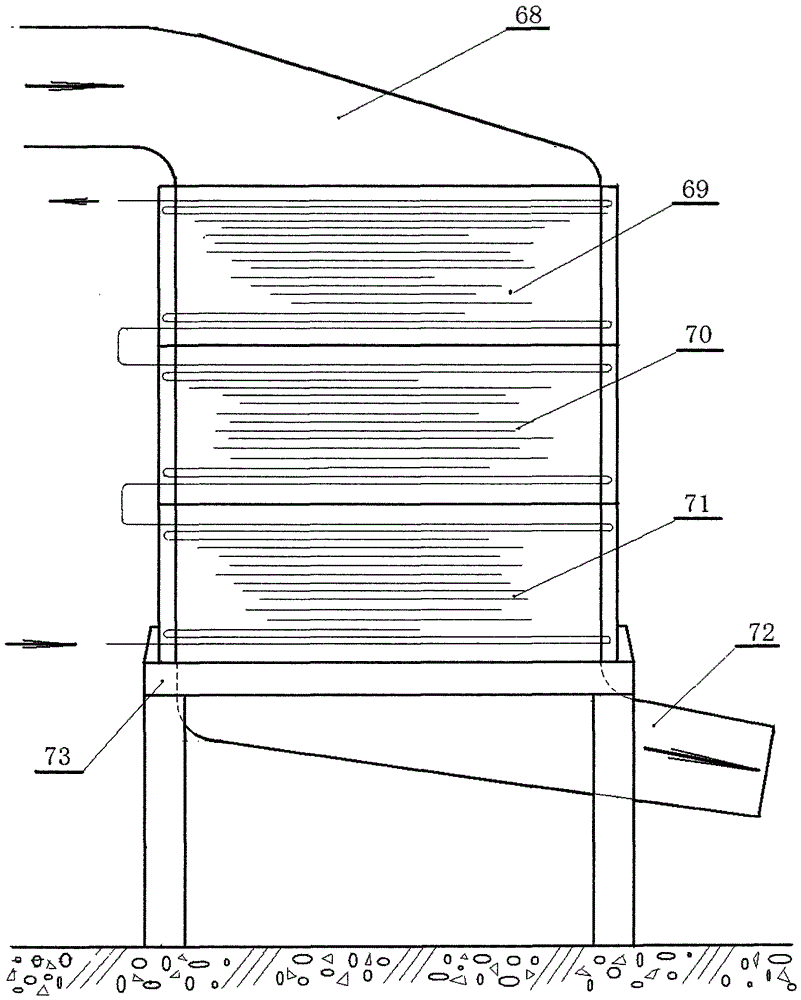

[0063] The technical feature of the ultra-low temperature economizer used in the double reheating unit of the present invention is a condensing heating surface arranged in the low-dust area between the outlet of the induced draft fan and the inlet of the desulfurization tower, which can reduce the flue gas temperature to 50°C ;Each secondary reheat coal-fired boiler is equipped with 2 ultra-low temperature economizers, one set on the flue gas flow channel on side A and side B; each ultra-low temperature economizer is divided by 4 flue gas flow channels Each boiler has a total of 8 equally divided flue gas distribution channels; the horizontally arranged highly ribbed finned tubes are the heat exchange main body in each flue gas distribution channel, and the upper and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com