Self-insulation hollow block brick for wall and preparation method thereof

A technology of hollow block and self-insulation, applied in insulation, building components, buildings, etc., can solve the problems of poor low-temperature resistance, low compressive strength, and high insulation cost, and achieve good construction performance, high compressive strength, physical and chemical The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

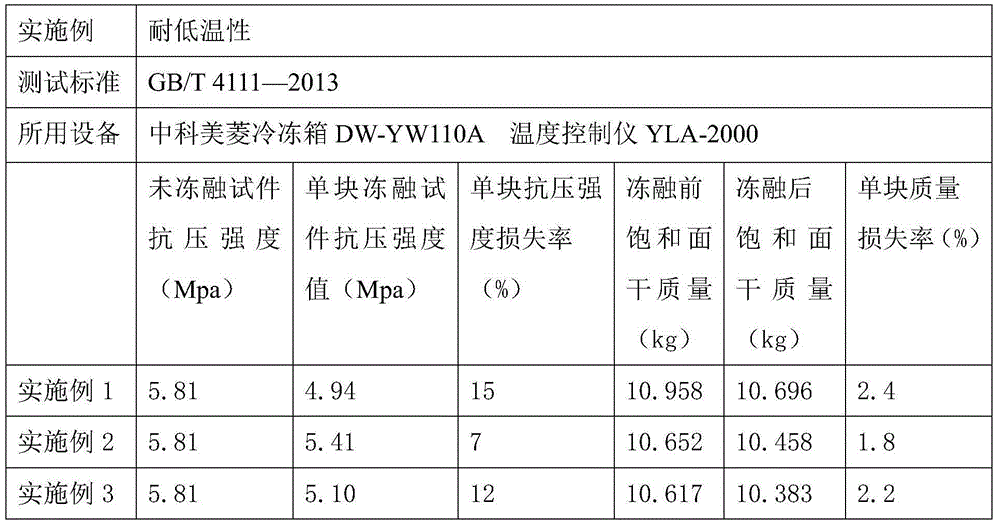

Embodiment 1

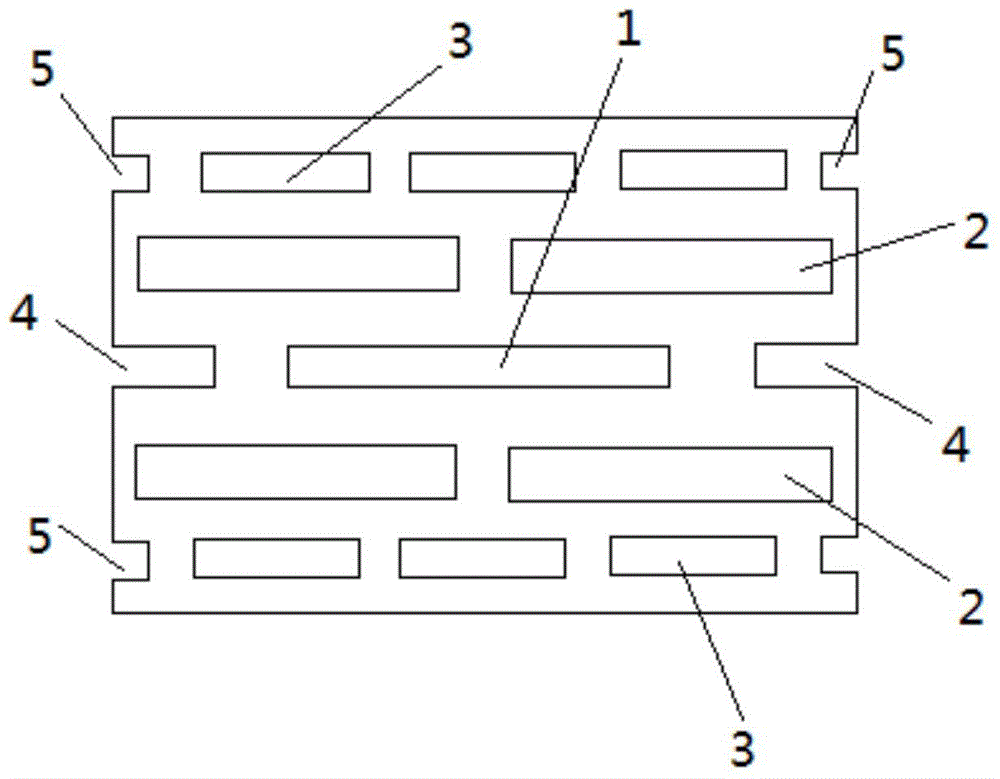

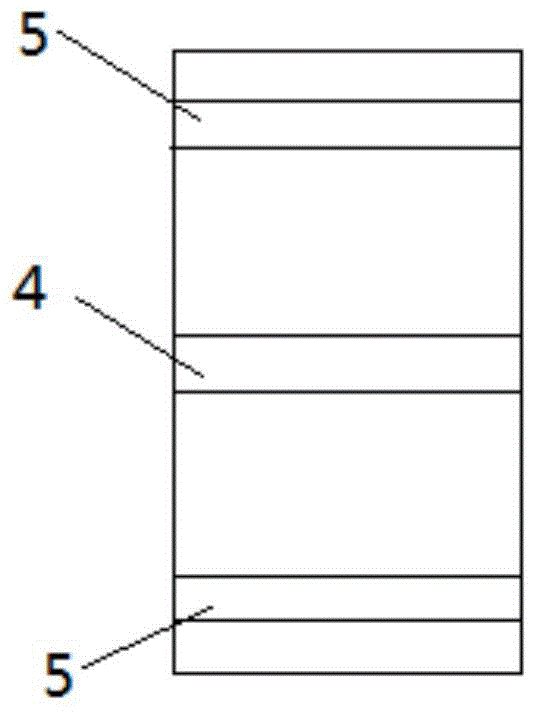

[0029] Such as figure 1 The shown wall uses self-insulating hollow block bricks, including the block brick body. The block brick body is provided with five rows of long through holes running through the thickness direction of the block brick body. Each row of long through holes is along the The length direction of the block brick body is set, and the length direction of the long through hole is consistent with the length direction along the block brick body; the two sides in the length direction of the block brick are smooth surfaces, and the two sides in the width direction of the block brick are set There is a through groove running through the thickness direction of the block brick body; the length of the block brick is 360mm, the width is 240mm, and the thickness is 120mm.

[0030] The five rows of elongated through holes include one row of first elongated through holes, two rows of second elongated through holes and two rows of third elongated through holes; wherein, the ...

Embodiment 2

[0036] It is basically the same as Example 1, except that its raw material components include: 12 parts of silicate cotton, 6 parts of aluminum silicate cotton, 22 parts of vitrified floating beads, 36 parts of cement, 31 parts of calcium sulfate, glass bleach 2 parts of beads, 3 parts of mineral powder and 0.8 part of inorganic adhesive, and the said parts are parts by mass.

Embodiment 3

[0038] It is basically the same as Example 1, except that its raw material components include: 18 parts of silicate cotton, 9 parts of aluminum silicate cotton, 28 parts of vitrified floating beads, 39 parts of cement, 34 parts of calcium sulfate, glass bleach 3 parts of beads, 4 parts of mineral powder and 1.5 parts of inorganic adhesive, the said parts are parts by mass.

[0039]The silicate cotton and aluminum silicate cotton used in each embodiment are all recovered from the waste insulation materials of China Resources Power Plant; vitrified floating beads, first grade, purchased from Lingshou County Huayi Mineral Products Processing Factory; cement is silicate Cement grade 42.5; glass floating beads 40 mesh, purchased from Lingshou County Zhenyang Mineral Powder Processing Factory; mineral powder grade S105, purchased from Lingshou County Wanhe Mineral Products Processing Factory; inorganic adhesive was purchased from Liancheng County Heng High-quality sodium-based bento...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com