Air jet assisting multi-needle electrostatic spinning device and method for preparing nanofiber net through air jet assisting multi-needle electrostatic spinning device

A nanofiber web and electrospinning technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve the problems of needle interference, Taylor cone shape and stability, and improve the volatilization speed , Accelerate the curing and running speed, and increase the output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

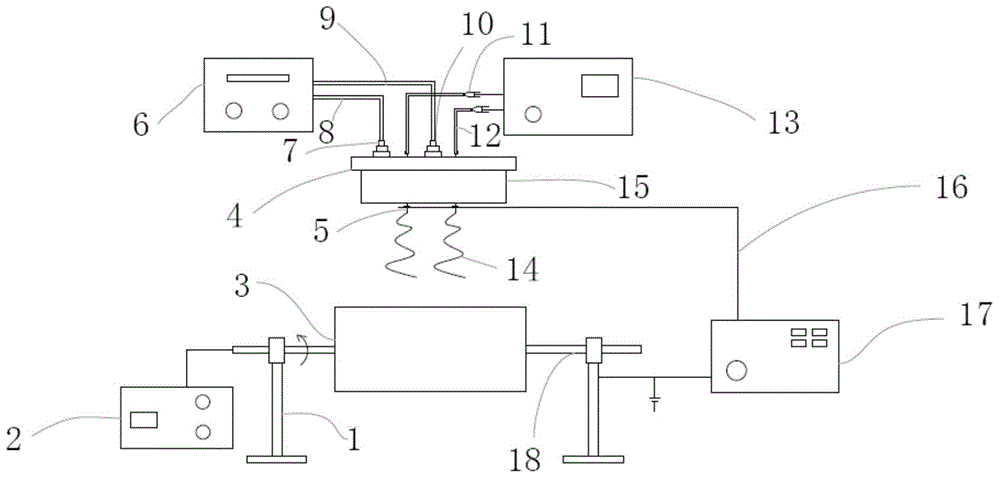

Embodiment 1

[0047] Dissolve polyacrylonitrile (PAN) in solvent N,N-dimethylformamide (DMF) to prepare a spinning solution with a concentration of 13 wt%. Inject the spinning solution into the syringe 11 of the multi-needle electrospinning device. In an environment at room temperature and 40% relative humidity, turn on the micro syringe pump 13 until the spinning solution circulates normally and set the flow rate to 0.3 mL / h. Turn on the DC high-voltage generator 17, the control voltage is 20kV, and then turn on the air compressor 6, and control the airflow speed to 4m / s. The electrospinning jet is deposited on the surface of the roller 3 in a spiral motion trajectory. The receiving distance between the needle 5 and the roller 3 is 100mm. At this time, the motor 2 is turned on to drive the roller 3 to rotate at a speed of 200r / min. Experimental results show that using this electrostatic spinning equipment to spin, the output per unit time of nanofibers is increased by 50%, the fineness of t...

Embodiment 2

[0049] The polyvinyl alcohol (PVA) 1788 powder was dissolved in distilled water at 70°C to prepare a spinning solution with a concentration of 16% by weight. Inject the spinning solution into the syringe 11 of the multi-needle electrospinning device. At room temperature and a relative humidity of 60%, turn on the micro syringe pump 13 and wait for the spinning solution to circulate normally and set the flow rate to 0.5 mL / h. Turn on the DC high-voltage generator 17, the control voltage is 40kV, and then turn on the air compressor 6, and control the airflow speed to 5m / s. The electrospinning jet is deposited on the surface of the roller 3 in a spiral motion trajectory. The receiving distance between the needle 5 and the roller 3 is 200mm. At this time, the motor 2 is turned on to drive the roller 3 to rotate at a speed of 500r / min. Experimental results show that using this electrostatic spinning equipment to spin, the output per unit time of nanofibers is increased by 60%, the f...

Embodiment 3

[0051] Polyethylene oxide (PEO) was dissolved in distilled water at 60°C to prepare a spinning solution with a concentration of 14% by weight. Inject the spinning solution into the syringe 11 of the multi-needle electrospinning device. In an environment at room temperature and 50% relative humidity, turn on the micro-injection pump 13 and wait for the spinning solution to circulate normally and set the flow rate to 0.4 mL / h. Turn on the DC high-voltage generator 17 with a control voltage of 30kV, and then turn on the air compressor 6 to control the airflow speed at 6m / s. The electrospinning jet is deposited on the surface of the roller 3 in a spiral motion trajectory. The receiving distance between the needle 5 and the roller 3 is 150 mm. At this time, the motor 2 is turned on to drive the roller 3 to rotate at a speed of 350 r / min. Experimental results show that using this electrostatic spinning equipment to spin, the output per unit time of nanofibers is increased by 55%, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com