Dry-type bamboo chopstick processing method

A processing method and dry technology, applied in the direction of wood processing equipment, manufacturing tools, etc., can solve the problems of long production cycle, reduced product hardness, complex processing procedures, etc., to achieve the increase of bamboo material rate, shorten the production cycle, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention is not limited to the specific embodiments listed below, but also includes any combination of the specific embodiments.

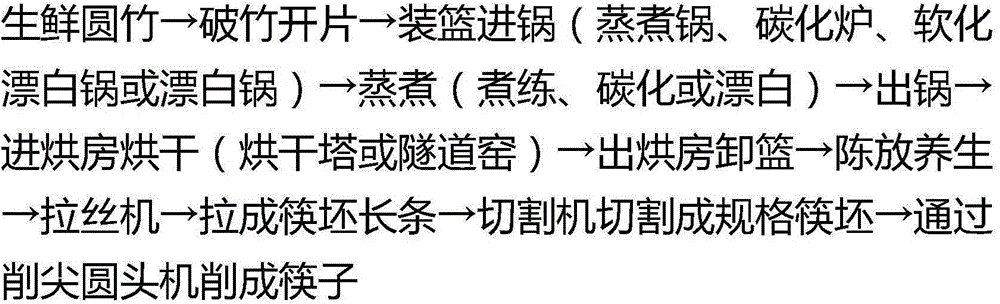

[0032] A dry processing method for bamboo chopsticks. The bamboo chopsticks are processed into kitchen utensils and tableware or bamboo shreds, bamboo slices, bamboo strips, bamboo blocks, and bamboo tubes after first steaming, drying, shrinking and shaping the bamboo materials, including the following processing steps:

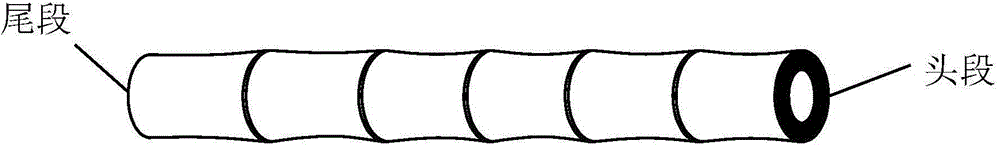

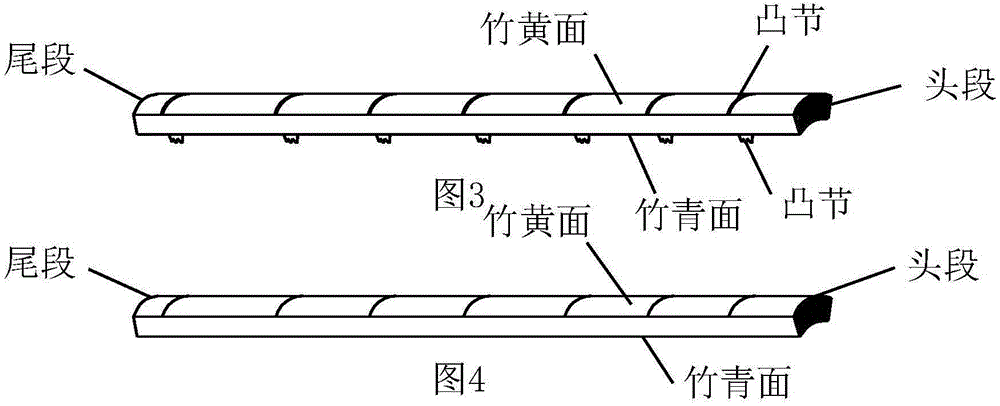

[0033] ①□Slicing: Fresh round bamboo is processed (cut into sections by a bamboo sawing machine produced by Zhejiang Anji Hengli Machinery Co., Ltd. and then broken by a bamboo bumper produced by Zhejiang Anji Hengli Machinery Co., Ltd.) into rules corresponding to the specifications of chopsticks or Irregular wool strips or rough strips or rough planed strips or trapezoidal bamboo strips; the width can be according to the specification of a single chopstick or a pair of chopsticks juxt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com