System and method for hot billet pressure control for round billet continuous caster

A round billet continuous casting and continuous casting billet technology, which is applied in the field of hot billet pressure control system of round billet continuous casting machine, can solve the problems of insufficient round billet, indentation roundness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with specific examples.

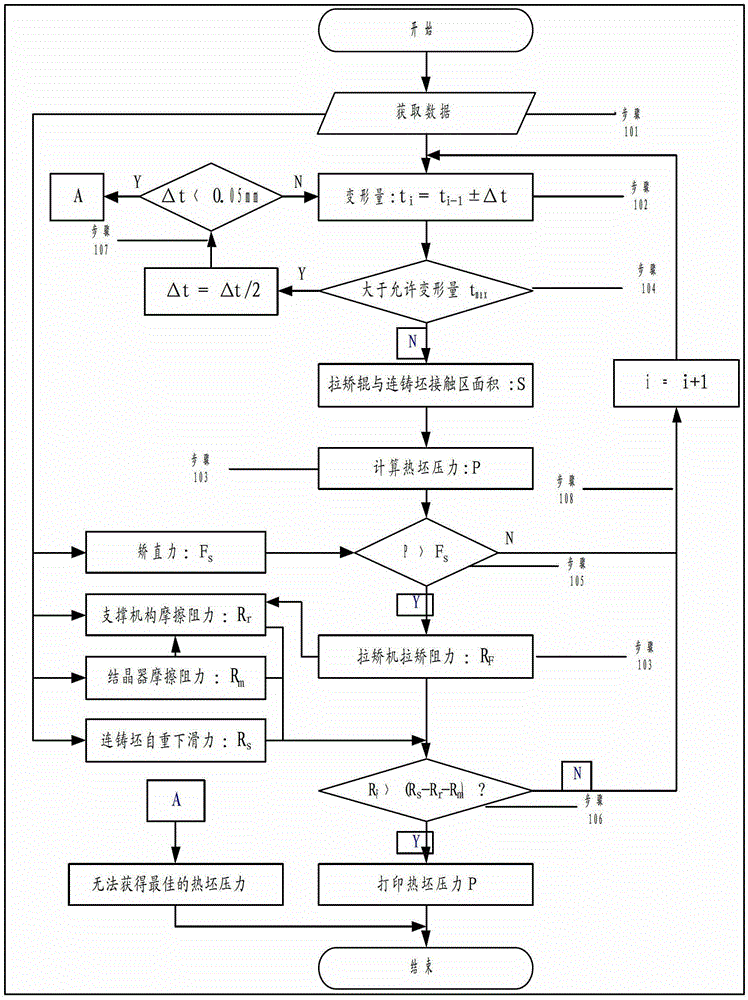

[0064] An embodiment of the present invention provides a hot billet pressure control system for a round billet continuous casting machine, including a parameter acquisition module, a first calculation module, a second calculation module, a first judgment module, a second judgment module, a third judgment module, a an adjustment module and a second adjustment module;

[0065] The parameter acquisition module is used to obtain the performance parameters of the continuous casting machine, the maximum surface indentation deformation, the initial surface indentation deformation and the deformation step;

[0066] The first calculation module is used to calculate the surface indentation deformation according to the initial surface indentation deformation and the deformation step;

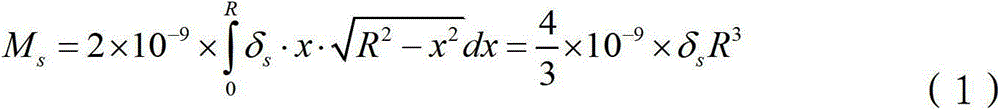

[0067] The second calculation module is used to calculate mold friction resistance, continuous casting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com