Combined roller structure for cold bending forming machine

A technology of cold roll forming machine and combined roll, which is applied in the field of combined roll structure of cold roll forming machine, which can solve the problems affecting the appearance of formed products, empty bending, etc., and achieve the effect of simple structure, smooth surface, and reduced surface indentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

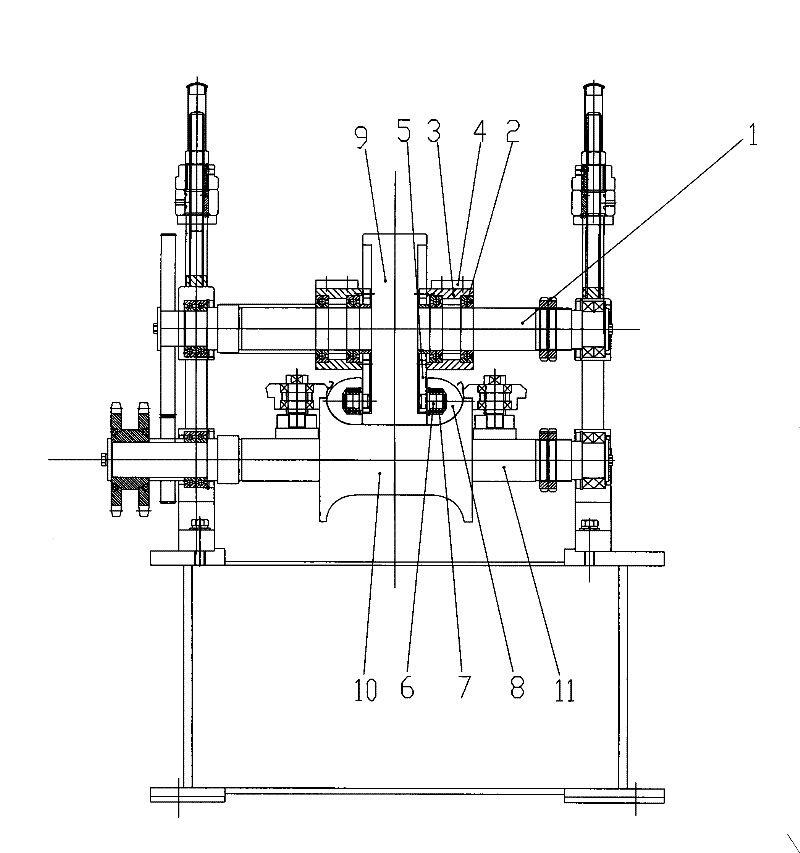

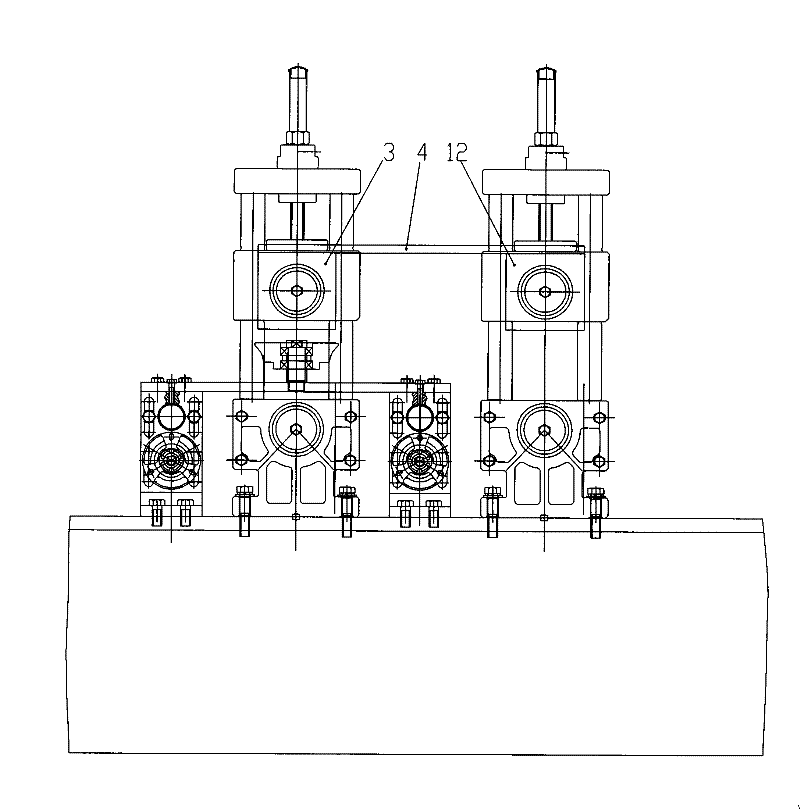

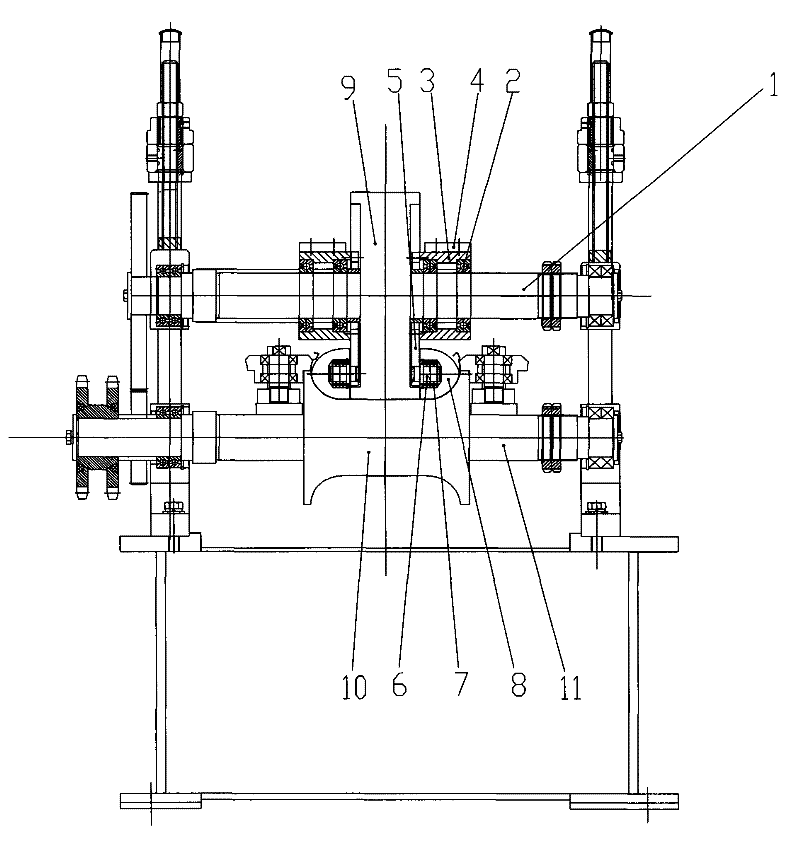

[0010] Such as Figure 1-2 Shown includes upper shaft 1, bearing 2, auxiliary bearing seat 3, first connecting plate 4, second connecting plate 5, small shaft 6, bearing 7, auxiliary roller 8, upper roller 9, lower roller 10, lower shaft 11, Auxiliary bearing housing 12 and so on.

[0011] In the present invention, the upper shaft 1 is fixed with the upper roller 9, the auxiliary bearing seat 3 is connected with the upper shaft through the bearing 2, the second connecting plate 5 is fixed with the auxiliary bearing seat 3, the small shaft 6 is fixed with the second connecting plate 5, and the auxiliary roller 8 The bearing 7 is connected with the small shaft 6, the lower roller 10 is fixed with the lower shaft 11, and the auxiliary bearing seat 3 is connected with the auxiliary bearing seat 12 through the first connecting plate 4 to prevent the auxili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com