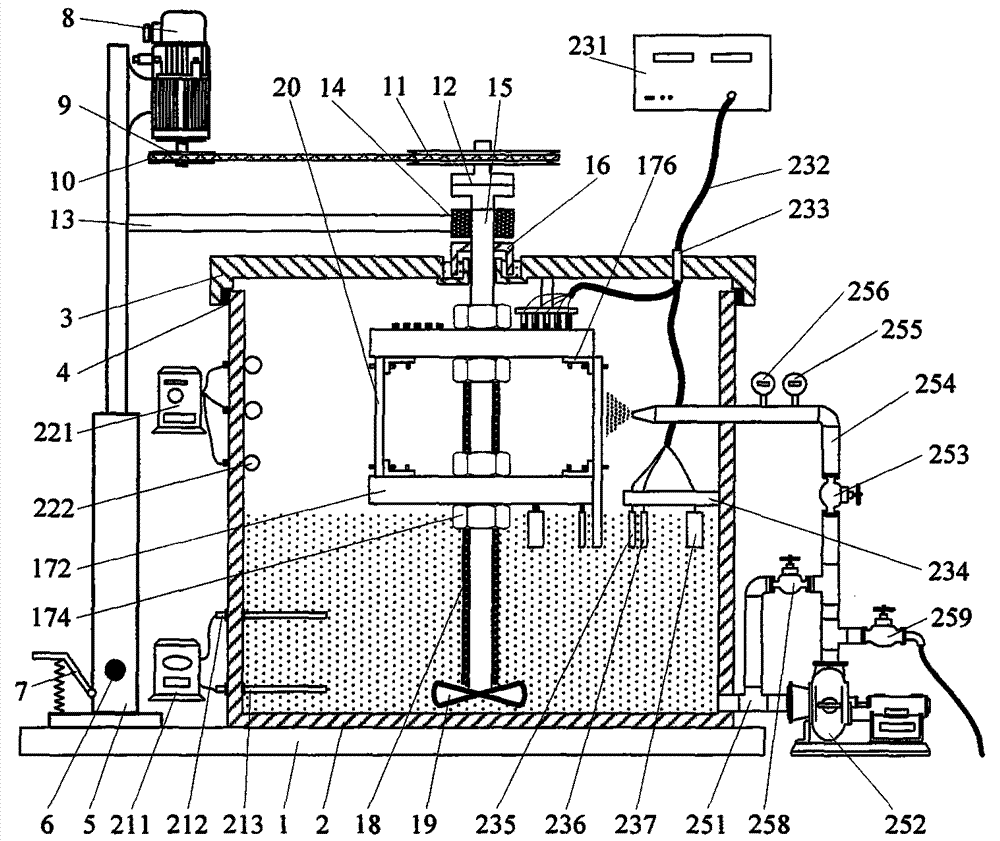

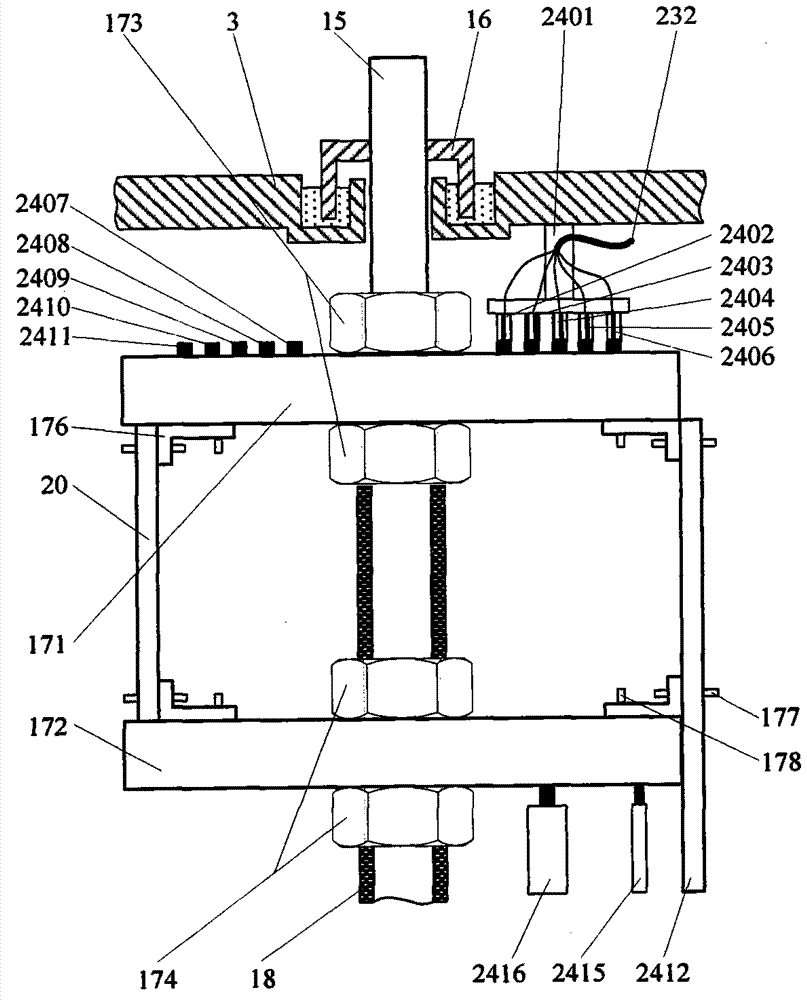

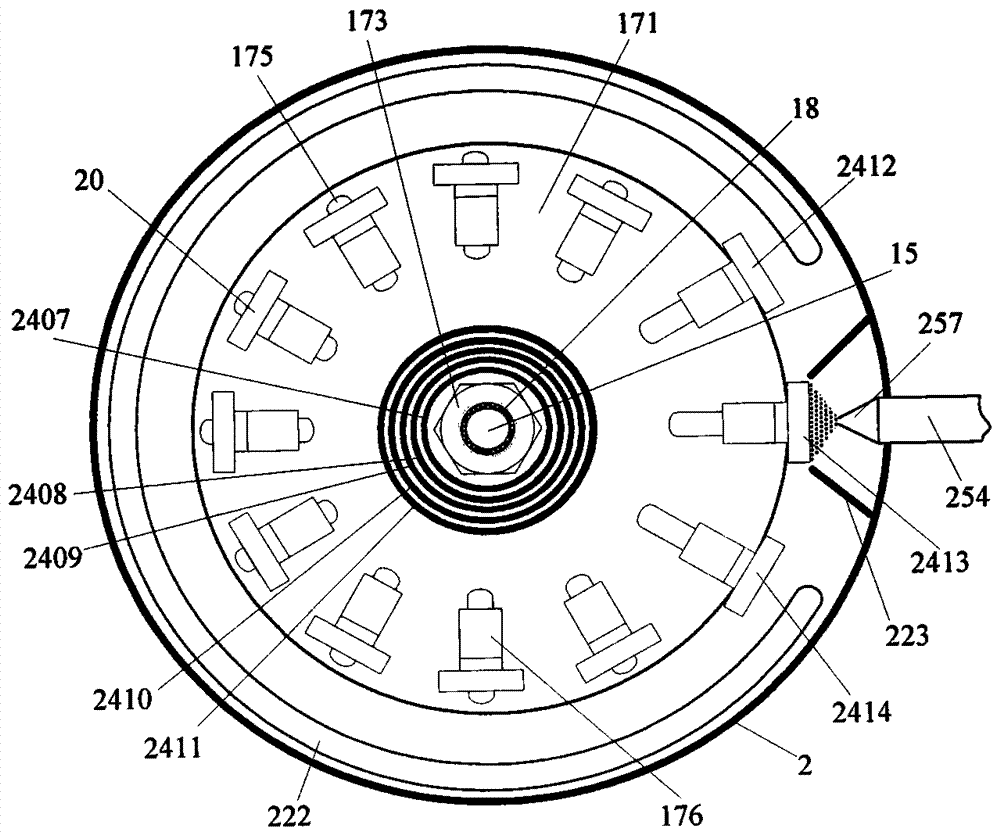

An erosion-corrosion experimental device for simulating spray splash zone

A technique for spray splashing and corrosion experiments, which is applied to measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., and can solve the problems that the results of synergistic effects cannot be included in the research scope, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Using relevant equipment, using NaOH to adjust the pH to 8 3.5% NaCl solution, under the conditions of impact velocity 5.4m / s and impact frequency 1Hz, the arc aluminum coating, the bottom zinc surface aluminum coating, the zinc-aluminum pseudo-alloy coating, The erosion-corrosion rate of Al-Ti coatings changed with time and the corrosion current density were compared and studied, and the erosion failure mechanism was analyzed.

[0027] (1) The erosion morphology of carbon steel in the simulated splash zone is mainly corrosion pits and streamline corrosion. Corrosion pits appear in the parts directly impacted by water jets, while the streamline corrosion outside the impact angle is caused by gas-liquid two-phase flow . Cavitation plays an important role in the metal corrosion failure process in the splash zone, and improving the micro-cutting resistance of the material is beneficial to improving the erosion resistance of the material.

[0028] (2) Both the bottom zinc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com