A prestressed industrial material yard shed structure and construction method

A prestressed and prestressed steel truss technology is applied in the field of prestressed industrial yard canopy structure and construction, which can solve the problems of large thrust of arched truss support, poor overall stability, and dense truss spacing, so as to reduce costs and reduce The effect of wasting resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

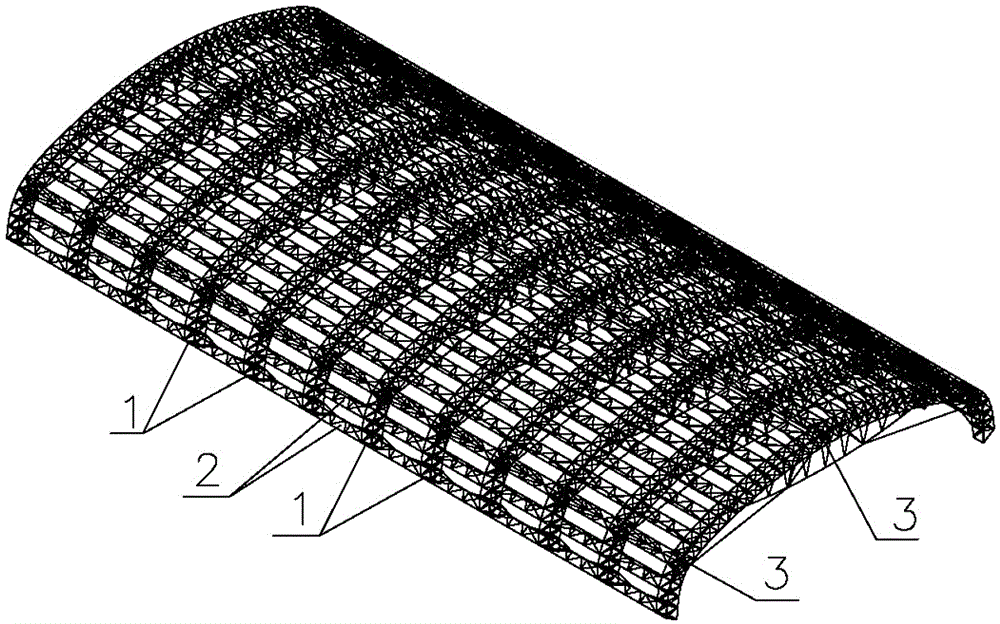

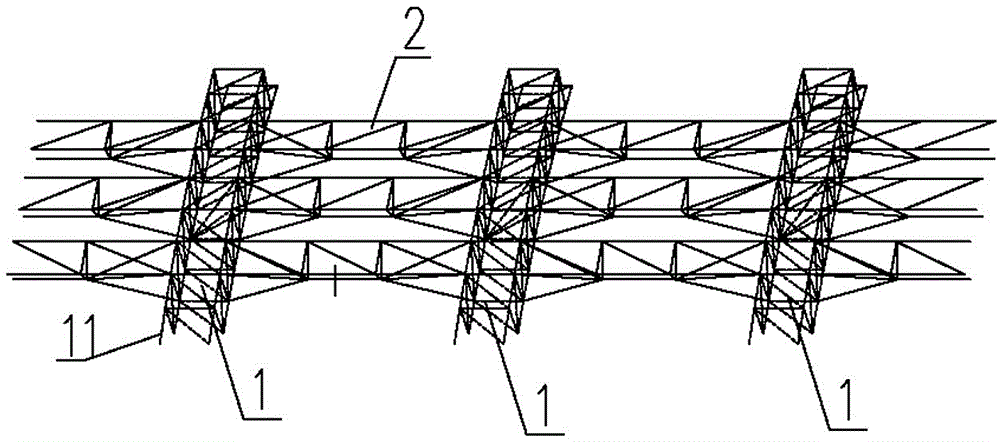

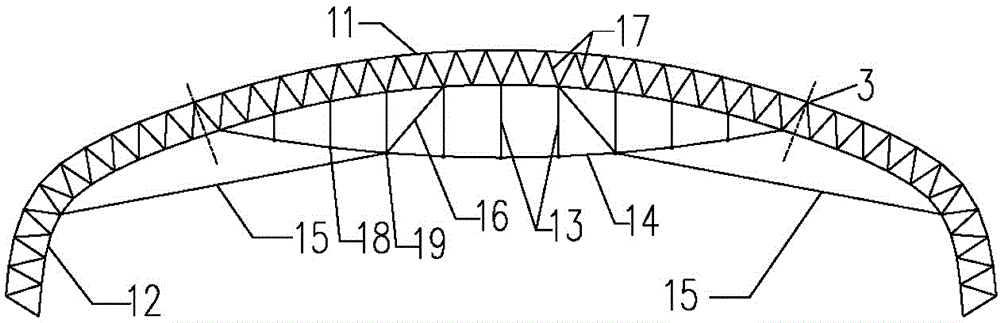

[0042] like Figure 1 to Figure 8 As shown, Example 1 is a composite structural system in which space string beams and arc-shaped prestressed steel trusses are used for super-long-span buildings, and is composed of arc-shaped prestressed steel trusses 1, space string beams 2, and longitudinally stable trusses 3; prestressed steel trusses The truss quadrilateral of truss 1 has a spacing of 36m, a total of 12 trusses, arranged in parallel, with a span of 180m, a height of 8m, and a width of 6m; three longitudinal stabilizing trusses 3 are arranged on the top and both sides of the prestressed steel truss, and no longitudinal stabilizing trusses are set Arrange the string beams in the space.

[0043] The prestressed steel truss 1 is composed of a truss upper chord 11 , a truss lower chord 12 , a truss web 17 , a strut 13 , a lower chord cable 14 , stay cables 15 , and a diagonal brace 16 . Among them, the upper chord 11 of the truss, the lower chord 12 of the truss, and the web o...

Embodiment 2

[0048] like Figure 9 to Figure 10 As shown, Example 2 is a composite structural system in which space string beams and square prestressed steel trusses are used for super-long-span buildings, and is composed of square prestressed steel trusses 1, space string beams 2, and longitudinally stable trusses 3; prestressed steel trusses 1 The truss quadrilateral has a spacing of 36m, a total of 12 trusses, arranged in parallel, with a span of 180m, a height of 8m, and a width of 6m; three longitudinal stabilizing trusses 3 are arranged on the top and both sides of the prestressed steel truss, and the space for the position without longitudinal stabilizing trusses is arranged Zhang Xianliang.

[0049] The construction method of the combined structure of prestressed steel truss and space tension beam of the present invention comprises the following steps:

[0050] First, complete the structural design.

[0051] Secondly, determine the construction plan, carry out the simulation anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com