A kind of film flocking type high elasticity antibacterial warm-keeping sheet material and its manufacturing method

A flake material, flocking technology, applied in chemical instruments and methods, non-woven fabrics, textiles and papermaking, etc., to achieve good elasticity, improved thermal insulation effect, and good appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Strip-shaped film flocking type machine-laid high-elastic antibacterial and warm-keeping sheet material and its preparation method:

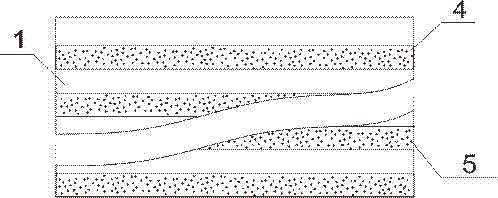

[0049] see figure 1 , figure 2 , film flocking type high elastic antibacterial and warm sheet material, including upper fiber web 1, upper hot-melt film 2, upper flocking film substrate 3, upper adhesive film 4, fluff 5, lower adhesive film 4' , Lower flocking film substrate 3', lower hot-melt film 2', lower fiber web 1', antibacterial agent 6, 6 , , the upper fiber web 1 and the lower fiber web 1' are three-dimensional crimped hollow polyester fibers with a fineness of 3D and a length of 51mm and low-melting fibers with a fineness of 3D and a length of 51mm and a melting point of 110°C, according to weight percentage 80%:20% is opened and mixed, and the fiber web prepared by mechanical carding of short fibers. Spray chitosan-containing antibacterial agent 6 inside the upper fiber web 1, and the lower layer fiber web 1 , Internal spr...

Embodiment 2

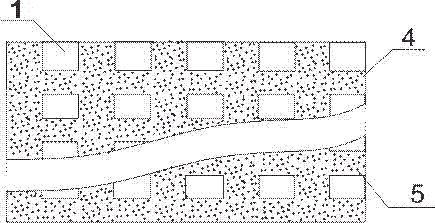

[0064] Grid-shaped film flocking type mechanically-laid high-elastic antibacterial and warm-keeping sheet material and its preparation method:

[0065] see figure 1 , image 3 , film flocking type high elastic antibacterial and warm sheet material, including upper fiber web 1, upper hot-melt film 2, upper flocking film substrate 3, upper adhesive film 4, fluff 5, lower adhesive film 4' , Lower flocking film substrate 3', lower hot-melt film 2', lower fiber web 1', antibacterial agent 6, 6 , , the upper fiber web 1 and the lower fiber web 1' are three-dimensional crimped hollow polyester fibers with a fineness of 3D and a length of 51mm and low-melting fibers with a fineness of 3D and a length of 51mm and a melting point of 110°C, according to weight percentage 80%:20% is opened and mixed, and the fiber web prepared by mechanical carding of short fibers. Spray chitosan-containing antibacterial agent 6 inside the upper fiber web 1, and the lower layer fiber web 1 , Internal ...

Embodiment 3

[0080] Strip-shaped film flocking air-laid high-elastic antibacterial and warm-keeping sheet material and its preparation method:

[0081] see figure 1 , figure 2 , film flocking type high elastic antibacterial and warm sheet material, including upper fiber web 1, upper hot-melt film 2, upper flocking film substrate 3, upper adhesive film 4, fluff 5, lower adhesive film 4' , Lower flocking film substrate 3', lower hot-melt film 2', lower fiber web 1', antibacterial agent 6, 6 , , the upper fiber web 1 and the lower fiber web 1' are three-dimensional crimped hollow polyester fibers with a fineness of 3D and a length of 51mm and low-melting fibers with a fineness of 3D and a length of 51mm and a melting point of 110°C, according to weight percentage 80%:20% is opened and mixed, and the fiber web is prepared by air-laying short fibers. Spray chitosan-containing antibacterial agent 6 inside the upper fiber web 1, and the lower layer fiber web 1 , Internal spraying with chitos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com