A kind of calcium-based liquid solidifying agent and method for fixing vanadium-contaminated soil in situ

A liquid curing agent, in-situ fixation technology, applied in chemical instruments and methods, soil conditioning materials, other chemical processes, etc., can solve the problems of less research on vanadium, soil pollution, excessive heavy metals associated with it, and achieve uniform distribution and environmental friendliness. , the effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

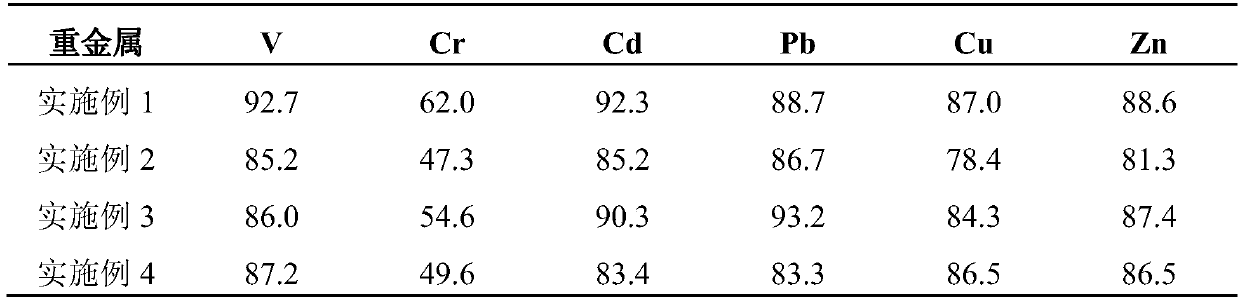

Embodiment 1

[0023] A calcium-based liquid curing agent, comprising 40.0 parts of curing agent A and 1.0 parts of curing agent B, curing agent A is prepared by mixing slaked lime with water at a mass ratio of 1.0:50.0, and curing agent B has a content of 40.0% Industrial grade sodium silicate, said parts are parts by mass;

[0024] The method for in-situ fixation of vanadium-contaminated soil by the calcium-based liquid solidifying agent comprises the following steps:

[0025] 1) Stir and mix curing agent A and curing agent B according to the mass parts of 40.0 parts and 1.0 parts;

[0026] 2) For surface vanadium-contaminated soil with a pollution depth within 20.0cm, spray the mixed slurry in step 1) evenly into the soil, and the spraying rate is 220.0L / m 2 , and mixed with plowing, the depth of plowing is 20.0cm, plowing 3 times, watering from time to time, keeping the moisture content at 20.0%, and maintaining for 5 days.

Embodiment 2

[0028] A calcium-based liquid curing agent, comprising 30.0 parts of curing agent A and 1.0 parts of curing agent B, curing agent A is made by mixing calcium chloride with water at a mass ratio of 1.0:25.0, and curing agent B has a content of 50.0 parts % of industrial grade sodium silicate, the parts are parts by mass;

[0029] The method for in-situ fixation of vanadium-contaminated soil by the calcium-based liquid solidifying agent comprises the following steps:

[0030] 1) Stir and mix curing agent A and curing agent B according to the mass parts of 30.0 parts and 1.0 parts;

[0031] 2) For surface vanadium-contaminated soil with a pollution depth within 20.0cm, spray the mixed slurry in step 1) evenly into the soil, and the spraying rate is 200.0L / m 2 , and mixed with plowing, the depth of plowing is 15.0cm, plowing 3 times, watering from time to time, keeping the moisture content at 30.0%, and maintaining for 5 days.

Embodiment 3

[0033] A calcium-based liquid curing agent, comprising 34.0 parts of curing agent A and 1.0 parts of curing agent B, curing agent A is made by mixing calcium dihydrogen phosphate with water at a mass ratio of 1.0:25.0, and curing agent B is the content 45.0% industrial grade sodium silicate, said parts are parts by mass;

[0034] The method for in-situ fixation of vanadium-contaminated soil by the calcium-based liquid solidifying agent comprises the following steps:

[0035] 1) Stir and mix curing agent A and curing agent B according to the mass parts of 34.0 parts and 1.0 parts;

[0036] 2) For surface vanadium-contaminated soil with a pollution depth within 20.0cm, spray the mixed slurry in step 1) evenly into the soil, and the spraying rate is 180.0L / m 2 , and mixed with plowing, the depth of plowing is 18.0cm, plowing 3 times, watering from time to time, keeping the moisture content at 25.0%, and maintaining for 5 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com