A preparation method of insulating material for aerospace cables

An insulating material, aerospace technology, applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve material failure, poor anti-atomic oxygen performance, physical and chemical erosion hazards specific heat vacuum, ultraviolet radiation , cold and hot alternation, micrometeorites, space debris and other problems, to achieve the effect of improving compatibility, improving the performance of anti-atomic oxygen, improving compatibility and effective combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

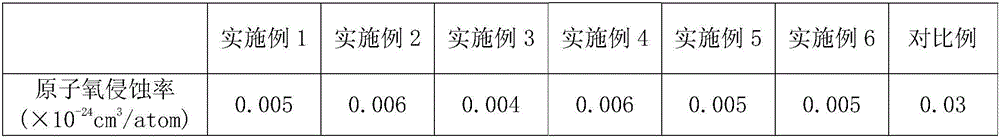

Examples

Embodiment 1

[0029] A preparation method for an insulating material for aerospace cables, the steps are as follows:

[0030] (1) Add aluminum nitrate nonahydrate into distilled water and stir evenly, add PEG and continue to stir for 1 hour, then add urea, the weight ratio of aluminum nitrate nonahydrate, PEG, and urea is 5:4:4, move to the water in the hydrothermal reaction kettle Heat reaction for 20 hours, after natural cooling, wash the obtained precipitate with water and ethanol for 5 times respectively, obtain aluminum ammonium carbonate fiber after suction filtration, place the aluminum ammonium carbonate fiber in a calciner at 1350°C and calcinate to obtain alumina fiber;

[0031] (2) Place the alumina fiber obtained in step (1) in a vacuum oven and dry it at 80°C for 2 hours, add the dried alumina fiber into the SDBS aqueous solution, and the weight ratio of the alumina fiber to SDBS is 12: 1. After 2 hours of magnetic stirring, reflux at 100°C for 2 hours, centrifuge after dischar...

Embodiment 2

[0035] A preparation method for an insulating material for aerospace cables, the steps are as follows:

[0036] (1) Add aluminum nitrate nonahydrate into distilled water and stir evenly, add PEG and continue to stir for 1 hour, then add urea, the weight ratio of aluminum nitrate nonahydrate, PEG, and urea is 5:4:4, move to the water in the hydrothermal reaction kettle Heat reaction for 20 hours, after natural cooling, wash the obtained precipitate with water and ethanol for 5 times respectively, obtain aluminum ammonium carbonate fiber after suction filtration, place the aluminum ammonium carbonate fiber in a calciner at 1350°C and calcinate to obtain alumina fiber;

[0037] (2) Place the alumina fiber obtained in step (1) in a vacuum oven and dry it at 80°C for 2 hours, add the dried alumina fiber into the SDBS aqueous solution, and the weight ratio of the alumina fiber to SDBS is 12: 1. After 2 hours of magnetic stirring, reflux at 100°C for 2 hours, centrifuge after dischar...

Embodiment 3

[0041] A preparation method for an insulating material for aerospace cables, the steps are as follows:

[0042] (1) Add aluminum nitrate nonahydrate into distilled water and stir evenly, add PEG and continue to stir for 1 hour, then add urea, the weight ratio of aluminum nitrate nonahydrate, PEG, and urea is 5:4:4, move to the water in the hydrothermal reaction kettle Heat reaction for 20 hours, after natural cooling, wash the obtained precipitate with water and ethanol for 5 times respectively, obtain aluminum ammonium carbonate fiber after suction filtration, place the aluminum ammonium carbonate fiber in a calciner at 1350°C and calcinate to obtain alumina fiber;

[0043] (2) Place the alumina fiber obtained in step (1) in a vacuum oven and dry it at 80°C for 2 hours, add the dried alumina fiber into the SDBS aqueous solution, and the weight ratio of the alumina fiber to SDBS is 12: 1. After 2 hours of magnetic stirring, reflux at 100°C for 2 hours, centrifuge after dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com