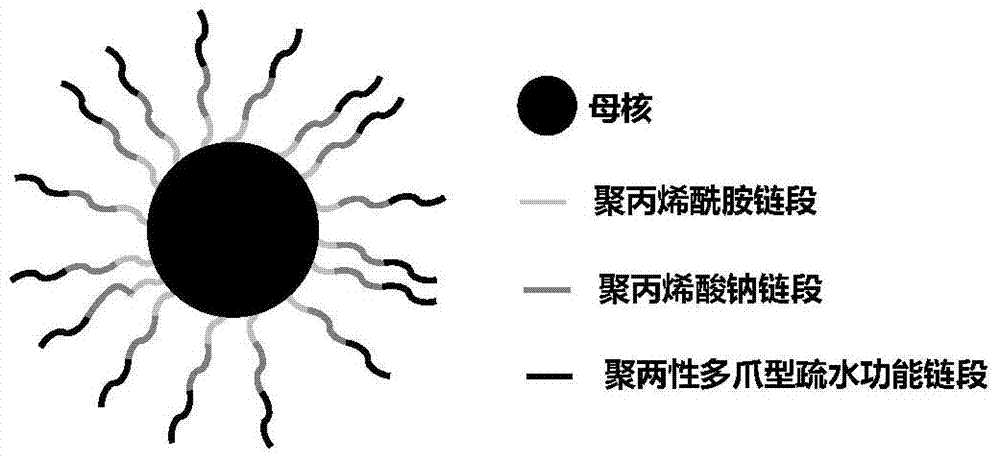

Hyperbranched polymer oil-displacing agent and preparation method thereof

A technology of hyperbranched polymer and oil displacing agent, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of complex process, high cost, harsh control of reaction conditions, etc., and achieve simple steps, mild conditions, The effect of good solubility and salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

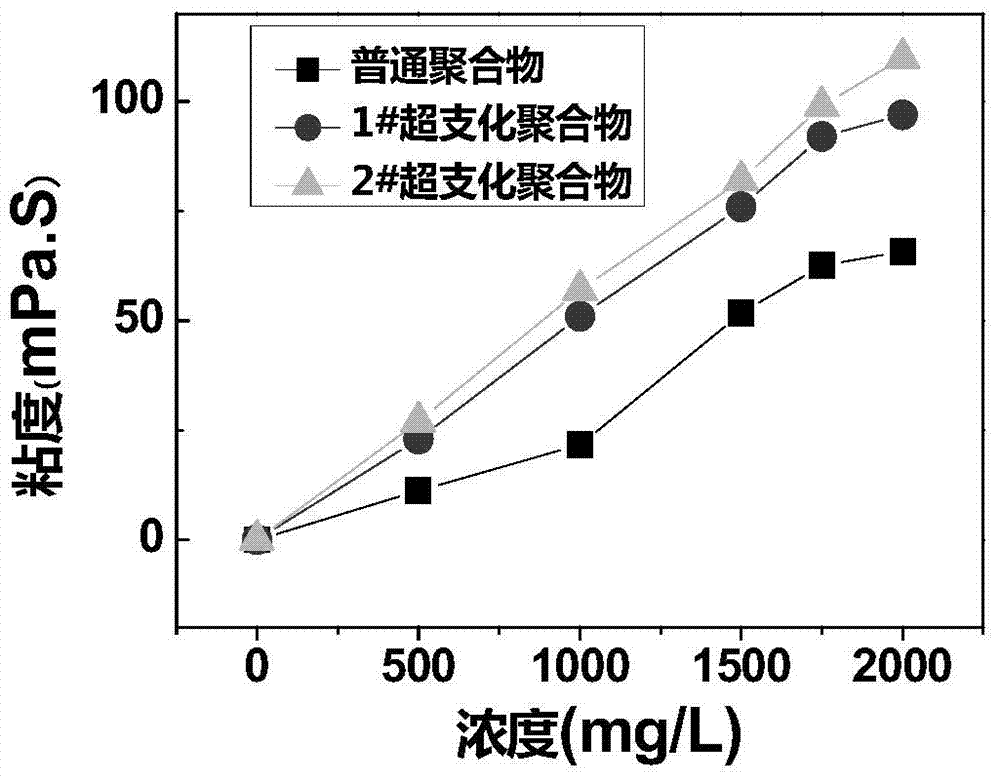

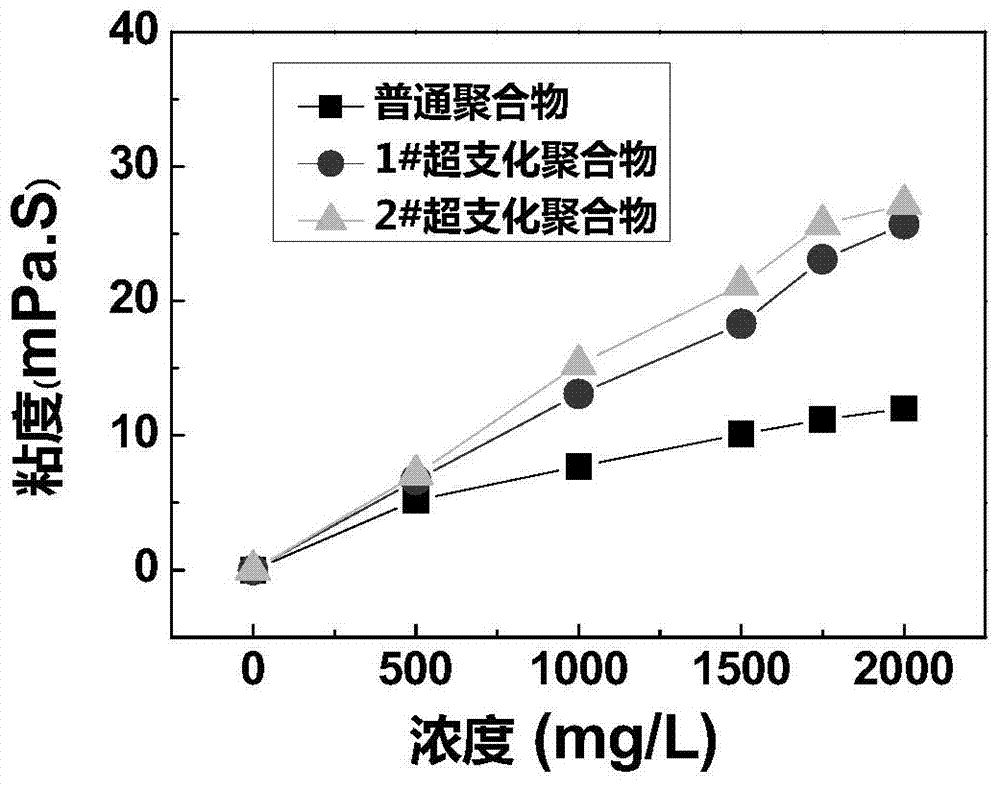

Embodiment 1

[0051] 25mg mother nucleus HPG, 85mL H 2 O was placed in a three-necked flask, stirred and dissolved, and nitrogen gas was introduced to remove oxygen for 45 minutes, and then an aqueous solution of ammonium cerium nitrate (50 mg of ammonium cerium nitrate dissolved in 10 mL of water) was added under the protection of nitrogen, and the reaction was stirred at 40 ° C for 30 minutes. Slowly add acrylamide aqueous solution (8.0g acrylamide dissolved in 22mL water), sodium acrylate aqueous solution (2.0g sodium acrylate dissolved in 10mL water), acrylic betaine functional monomer aqueous solution (200mg acrylic betaine functional monomer dissolved in 3mL water) , and then heated up to 55 ° C for 6 hours, and the resulting reaction solution was placed in a 70 ° C oven to dry and remove water, to obtain 1# hyperbranched polymer oil displacement agent.

Embodiment 2

[0053] 30mg mother core HPG, 85mL H 2 O was placed in a three-necked flask, stirred and dissolved, and nitrogen gas was introduced to deoxygenate for 45 minutes, then an aqueous solution of ammonium cerium nitrate (60 mg of ammonium cerium nitrate dissolved in 10 mL of water) was added under the protection of nitrogen, and stirred for 30 minutes at 40 ° C. Slowly add acrylamide aqueous solution (8.0g acrylamide dissolved in 22mL water), sodium acrylate aqueous solution (2.0g sodium acrylate dissolved in 10mL water), acrylate bromide quaternary ammonium salt monomer aqueous solution (400mg acrylate bromide quaternary in 3mL of water), then heated up to 55°C for 6 hours, and the resulting reaction liquid was dried in an oven at 70°C to remove water, and 2# hyperbranched polymer oil displacement agent was obtained.

[0054] The polymer performance evaluation method provided by the present invention and the results are as follows, wherein the unmodified partially hydrolyzed polyac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com