Synthetic method of phosphorothioate compound

A technology of phosphorothioate and synthesis method, which is applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., and can solve the problems of long reaction time, waste of raw materials, and inconsistency with atomic economy. and other problems, to achieve the effect of mild reaction conditions and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Synthesis of 2,4-dimethylphenyl di-n-propyl phosphorothioate (3a) from 2,4-dimethylthiophenol (2a) and di-n-propyl phosphite (1a):

[0035]

[0036] Add 1,3-dichloro-5,5-dimethylhydantoin (0.0493g, 0.25mmol) and dichloromethane (1.5mL) into a 10mL reaction flask equipped with magnetons, stir evenly at room temperature, and pour Add di-n-propyl phosphite (1a, 0.083g, 0.5mmol) and 2,4-dimethylthiophenol (2a, 0.069g, 0.5mmol), cover the lid, and stir vigorously at room temperature for 10 minutes; The completion of the reaction was monitored; the reaction solution was filtered, spin-dried and separated by column chromatography to obtain 0.139 g of a colorless transparent liquid (3a), with a yield of 92%.

[0037] R f =0.33(V 正己烷 / V 乙酸乙酯 =4 / 1); 1 H NMR (300MHz, CDCl 3 )δ7.47(dd, J=7.9, 2.3Hz, 1H), 7.07(s, 1H), 6.98(d, J=7.9Hz, 1H), 4.12-3.94(m, 4H), 2.48(s, 3H ), 2.30(d, J=2.1Hz, 3H), 1.66(dt, J=13.7, 6.9Hz, 4H), 0.92(t, J=7.4Hz, 6H); 13 C NMR (75MHz, CDCl 3 )δ142...

Embodiment 2

[0039] Synthesis of 2,4-dimethylphenyl di-n-propyl phosphorothioate (3a) from 2,4-dimethylthiophenol (2a) and di-n-propyl phosphite (1a):

[0040]

[0041] Operation method is the same as embodiment 1. The difference is that trichloroisocyanuric acid (0.04 g, 0.175 mmol) was used instead of 1,3-dichloro-5,5-dimethylhydantoin as the chlorination reagent. Obtained 0.133 g of a colorless transparent liquid (3a), with a yield of 88%.

[0042] R f =0.33(V 正己烷 / V 乙酸乙酯 =4 / 1); 1 H NMR (300MHz, CDCl 3)δ7.47(dd, J=7.9, 2.3Hz, 1H), 7.07(s, 1H), 6.98(d, J=7.9Hz, 1H), 4.12-3.94(m, 4H), 2.48(s, 3H ), 2.30(d, J=2.1Hz, 3H), 1.66(dt, J=13.7, 6.9Hz, 4H), 0.92(t, J=7.4Hz, 6H); 13 C NMR (75MHz, CDCl 3 )δ142.20 (d, J=5.4Hz), 139.72 (d, J=3.3Hz), 136.36 (d, J=4.2Hz), 131.84 (d, J=2.8Hz), 127.70 (d, J=2.8 Hz), 122.24(d, J=7.4Hz), 69.61(d, J=7.1Hz), 23.74(d, J=7.2Hz), 21.35(d, J=17.7Hz), 10.14(s); 31 P NMR (121MHz, CDCl 3 )δ23.54(s); MS(70eV, EI)C 14 h 23 o 3 PS[M]: 302.09.

Embodiment 3

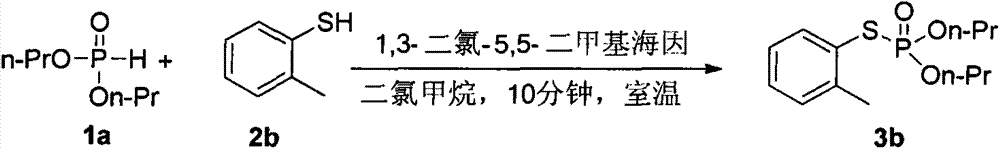

[0044] Synthesis of 2-methylphenyl di-n-propyl phosphorothioate (3b) from 2-methylthiophenol (2b) and di-n-propyl phosphite (1a):

[0045]

[0046] Operation method is the same as embodiment 1. The difference is that 2-methylthiophenol (2b) is used instead of 2,4-dimethylthiophenol (2a). 0.127 g of a colorless transparent liquid (3b) was obtained with a yield of 88%.

[0047] R f =0.34(V 正己烷 / V 乙酸乙酯 =4 / 1); 1 H NMR (300MHz, CDCl 3 )δ7.66-7.60 (m, 1H), 7.28 (d, J = 2.3Hz, 2H), 7.22-7.14 (m, 1H), 4.14-3.96 (m, 4H), 2.54 (d, J = 1.3Hz , 3H), 1.68(dd, J=14.0, 7.3Hz, 4H), 0.92(t, J=7.4Hz, 6H); 13 C NMR (75MHz, CDCl 3 )δ142.32 (d, J=5.7Hz), 136.28 (d, J=4.2Hz), 130.96 (d, J=2.6Hz), 129.50 (d, J=3.0Hz), 126.85 (d, J=2.7 Hz), 125.99(d, J=7.4Hz), 69.69(d, J=7.1Hz), 23.72(d, J=7.2Hz), 21.56(s), 10.12(s); 31 P NMR (121MHz, CDCl 3 )δ23.09(s); MS(70eV, EI)C 13 h 21 o 3 PS[M]: 288.02.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com