Long-chain mixed dicarboxylic acid purification method

A technology of mixing dibasic acids and dibasic acids, which is applied in the separation/purification of carboxylic acid compounds, chemical instruments and methods, and the preparation of organic compounds, etc. It can solve the problems of poor solubility, poor product appearance, and high-carbon dibasic acids High content and other issues, to achieve the effect of protecting the environment, increasing income, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

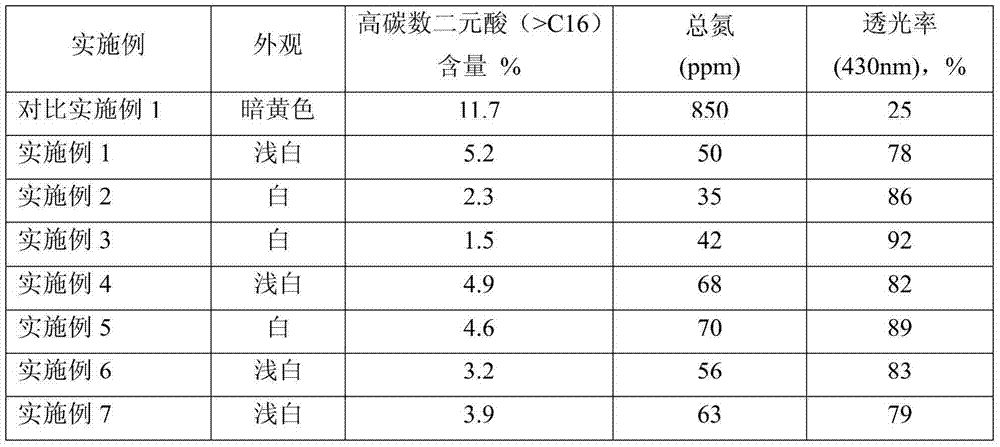

Examples

Embodiment 1

[0062] Take 100 grams of the by-product mixed dibasic acid obtained in the extraction process of dodecane dibasic acid, add 1800 grams of water, raise the temperature to 90 ° C, add caustic soda, adjust the pH to 5.7, stir, and the mixed dibasic acid is almost completely dissolved.

[0063] Add 3 grams of macroporous powder sugar carbon to the above solution, stir for 1 hour, and filter while hot to obtain a filtrate.

[0064] The obtained filtrate was stirred, cooled down at room temperature and precipitated. After the temperature dropped to 40°C, it was maintained for one hour, and then filtered to obtain a precipitate of large particles. Wash with 50g of cold water.

[0065] The obtained precipitate was added into 1000 g of water, heated to 80° C., stirred, and after adding 7 g of sodium hydroxide, the precipitate was completely dissolved.

[0066] Ozone is passed into the solution to carry out oxidation, and the amount of ozone passed into is controlled at 2% of the dry ...

Embodiment 2

[0070] Take 100 grams of the by-product mixed dibasic acid obtained in the extraction process of dodecane dibasic acid, add 400 grams of water, heat up to 90 ° C, add caustic soda, adjust the pH to 6.7, stir, and the mixed dibasic acid is almost completely dissolved.

[0071] The obtained filtrate was stirred, cooled down at room temperature and precipitated. After the temperature dropped to 30°C, it was maintained for one hour, and then filtered to obtain a precipitate of large particles. Wash with 50g of cold water.

[0072] The obtained precipitate was added into 1200 g of water, heated to 80° C., stirred, and after adding 2 g of sodium hydroxide, the precipitate was completely dissolved. Add 3 grams of macroporous powdered sugar carbon into the resulting solution, stir for 1 hour, and filter while hot to obtain a filtrate.

[0073] Ozone is passed into the solution to carry out oxidation, and the amount of ozone passed into is controlled at 5% of the dry weight of solid ...

Embodiment 3

[0077] Take 100 grams of the by-product mixed dibasic acid obtained in the extraction process of dodecane dibasic acid, add 200 grams of water, heat up to 95 ° C, add caustic soda, adjust the pH to 6.2, stir, and the mixed dibasic acid is almost completely dissolved.

[0078] Add 1 gram of macroporous powdered sugar carbon to the above solution, stir for 1 hour, and filter while hot to obtain a filtrate.

[0079] The obtained filtrate was stirred, cooled down at room temperature and precipitated. After the temperature dropped to 40°C, it was maintained for one hour, and then filtered to obtain a precipitate of large particles. Wash with 50g of cold water.

[0080] The obtained precipitate was added into 1000 g of water, heated to 80° C., stirred, and after adding 5 g of sodium hydroxide, the precipitate was completely dissolved.

[0081] Pass into ozone in solution and carry out oxidation, feed into the 8% of ozone amount control at solid 1 dry weight, and oxidation temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com