Crop compost and preparation method thereof

A crop and composting technology, applied in the field of crop resources, can solve the problems of low fertilizer efficiency of compost products, and achieve the effects of shortened composting cycle, low cost and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

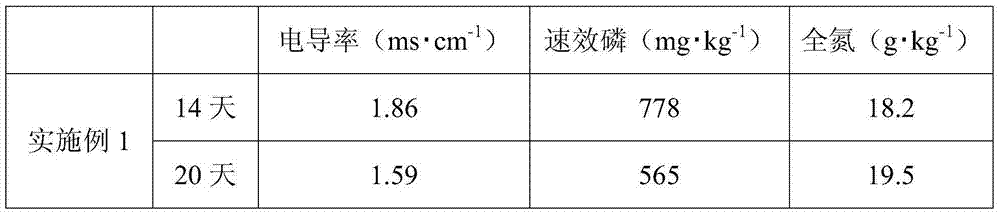

Examples

Embodiment 1

[0022] The livestock and poultry manure used in this example is pig manure, and the crop straw is wheat straw, which are respectively taken from a pig farm and an experimental field of Zhuanghang Experimental Station in Fengxian District, Shanghai. Among them, the moisture content of pig manure was 85.0%, and the mass fraction of organic carbon was 34.4% on a dry basis; the moisture content of straw was 9.1%, and the mass fraction of organic carbon was 62.6% on a dry basis.

[0023] Cut the wheat straw into 18-20cm segments, and bundle them into the closed carbonization furnace (Zhejiang Wuneng Environmental Protection Technology Development Co., Ltd., model ECO-5000) in the Zhuanghang Experimental Station. The speed is 100℃·h -1 It was carbonized under the condition of 500°C and kept warm for 1 hour to obtain straw biochar, which was wheat straw charcoal, and the conductivity of the prepared wheat straw biochar was 7.9ms·cm -1 , pH value 5.5, water-soluble organic carbon con...

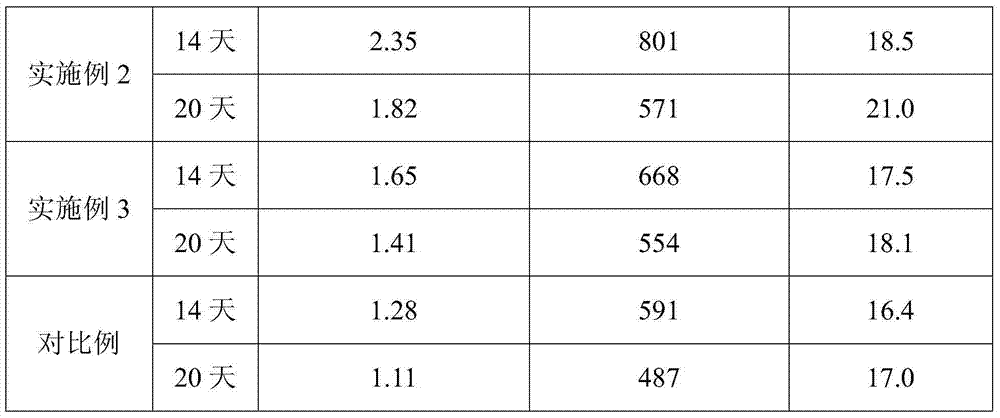

Embodiment 2

[0032] The livestock and poultry manure used in this example is pig manure, and the crop straw is wheat straw, which are respectively taken from a pig farm and an experimental field of Zhuanghang Experimental Station in Fengxian District, Shanghai. Among them, the moisture content of pig manure was 85%, and the mass fraction of organic carbon was 34.4% on a dry basis; the moisture content of straw was 9.1%, and the mass fraction of organic carbon was 62.6% on a dry basis.

[0033] Cut the wheat straw into 18-20cm segments, and bundle them into the closed carbonization furnace (model ECO-5000) in the Zhuanghang Experimental Station. -1 It was carbonized under certain conditions, raised to the final carbonization temperature and then kept for 1 hour to obtain straw biochar as wheat straw charcoal, and the conductivity of the prepared wheat straw biochar was 7.9ms·cm -1 , pH value 5.5, water-soluble organic carbon content 2.7g·kg -1 , Available phosphorus content 1100mg·kg -1 ,...

Embodiment 3

[0038] The livestock and poultry manure used in this example was pig manure, and the crop straw was rice straw, which were respectively taken from a pig farm and an experimental field of Zhuanghang Experimental Station in Fengxian District, Shanghai. Among them, the moisture content of pig manure was 85%, and the mass fraction of organic carbon was 34.4% on a dry basis; the moisture content of straw was 10.1%, and the mass fraction of organic carbon was 41.0% on a dry basis.

[0039] Cut the rice straw into 18-20cm segments, and bundle them into the closed carbonization furnace (model ECO-5000) in the Zhuanghang Experimental Station. -1 Carbonize it under certain conditions, raise it to the final carbonization temperature, and keep it warm for 1 hour to obtain straw biochar as rice straw charcoal. The conductivity of the rice straw biochar is 5.4ms·cm -1 , pH value 7.2, water-soluble organic carbon content 2.3g·kg -1 , Available phosphorus content 800mg·kg -1 , Nitrate nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com