Preparation method of flexible sintered ferrite films

A technology of sintering iron and ferrite powder, which is applied in the field of magnetic materials of radio frequency identification system (RFID), and can solve the problems of surrounding alternating magnetic field and eddy current loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

[0031] The present invention mainly relates to a preparation method of a flexible sintered ferrite diaphragm, which comprises the following specific steps:

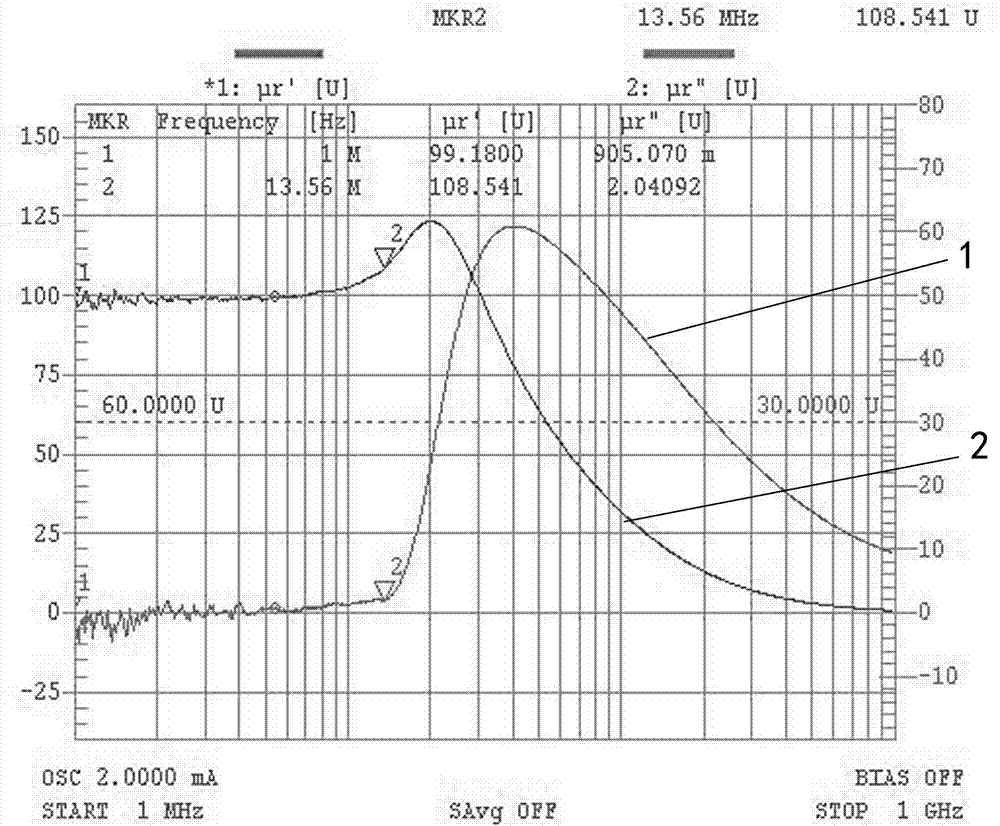

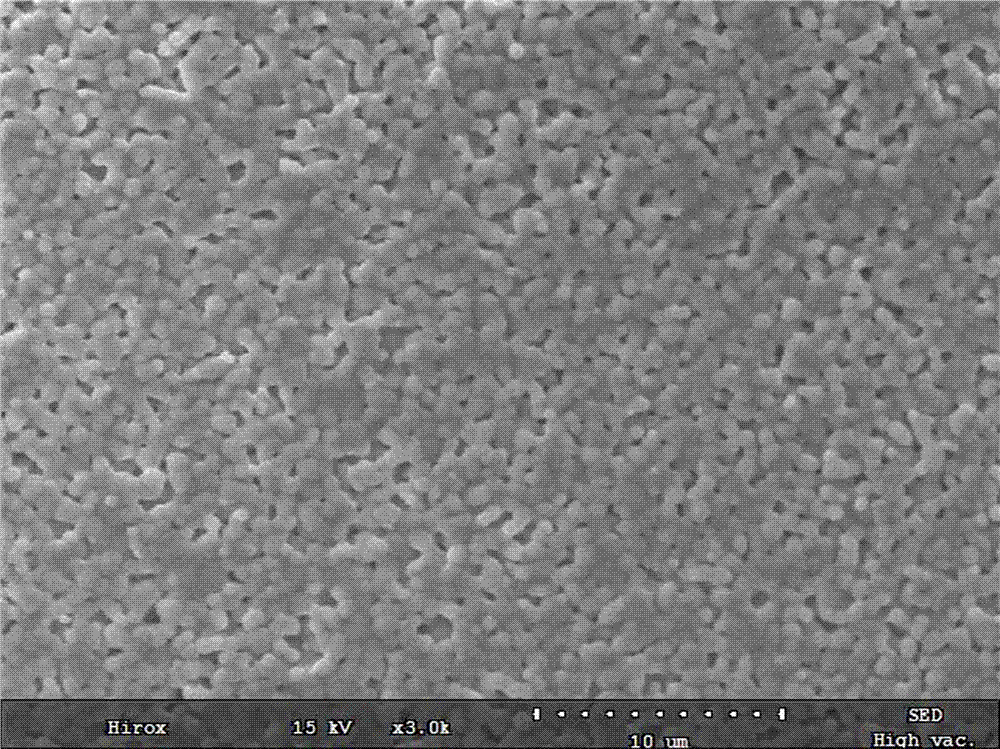

[0032] 1) Preparation of slurry: Add ferrite powder and solvent to the ball mill tank according to the preset ratio for ball milling. In this embodiment, the ferrite powder is selected with an average particle size of 1 μm and a magnetic permeability between 70 and 200. , and it is prepared from ferrite powder with low magnetic loss (typical value between 1~6). The preferred ferrite powder is ferrite with magnetic permeability of 150~160 and magnetic loss of 2~4 powder; in this example, a mixture of ethanol (EtOH) and butanone (MEK) is used as a solvent, wherein the mass ratio of ethanol and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com