A Capsule Tank with Stable Transmission Capability

A technology of transmission capacity and storage tank, which is applied in the direction of transportation of passenger cars, transportation and packaging, tank cars, etc. It can solve the problems of affecting oil flow, box damage, impact, etc., and achieve the effect of reducing flow resistance and improving discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

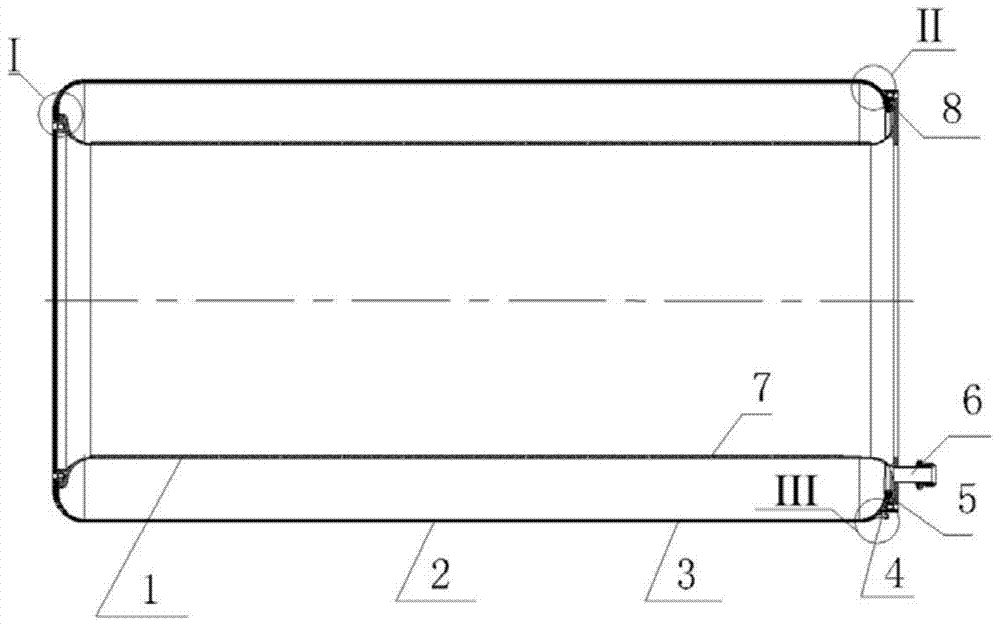

[0022] Such as figure 1 As shown, a capsule-type storage tank with stable transmission capacity includes a storage tank body, pipes and rubber capsules;

[0023] The bottom end of the pipe is fixedly connected with the bottom end of the tank body; through holes are evenly distributed on the side wall of the pipe;

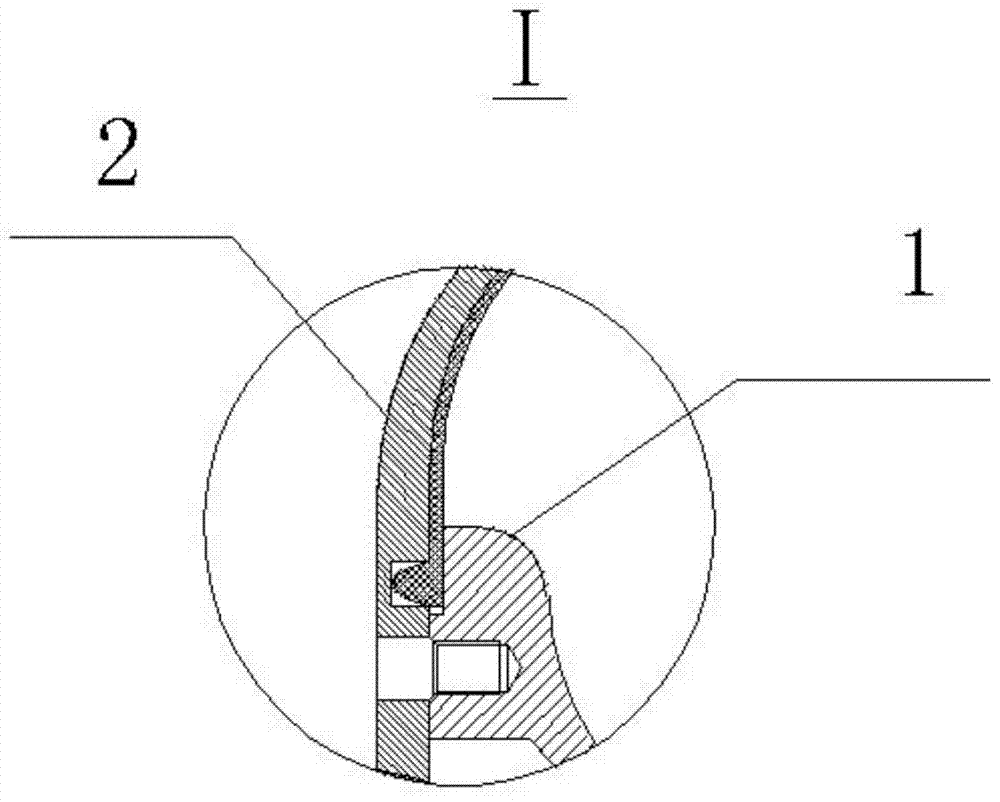

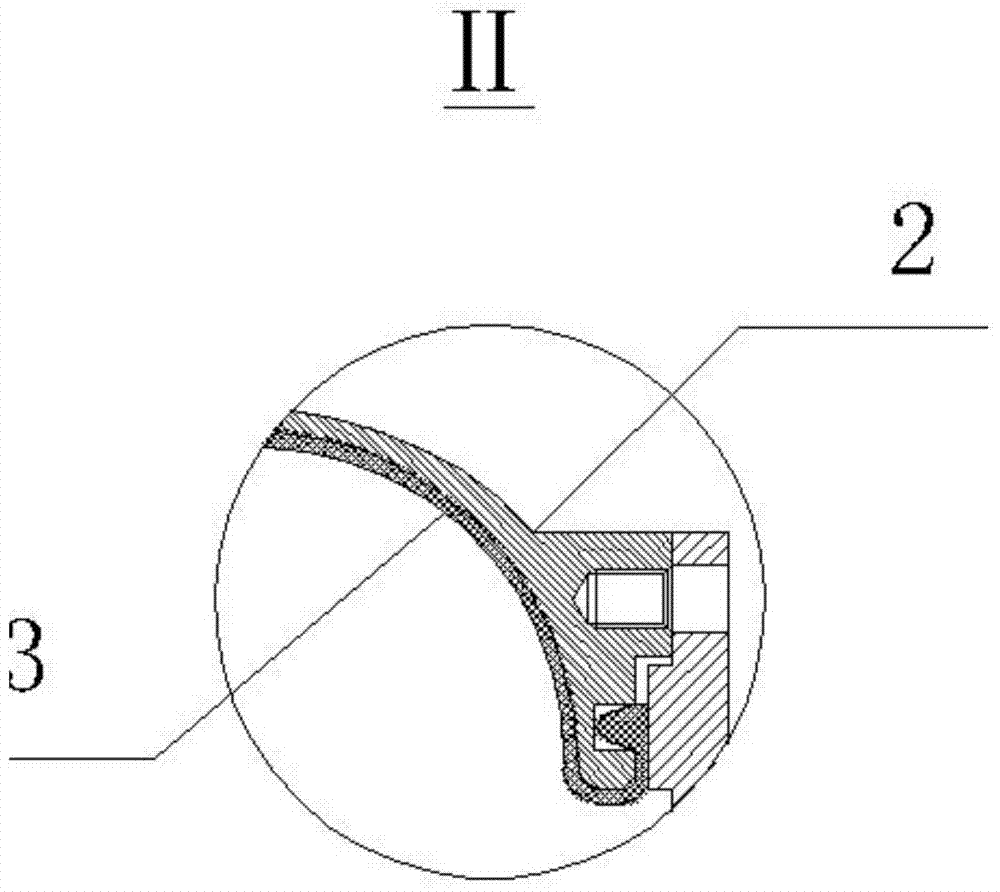

[0024] The rubber capsule is a flexible cylindrical structure with an upper opening and a lower opening, and the bottom and top of the rubber capsule have flanges;

[0025] The rubber capsule is set between the pipe and the tank body, the flange at the bottom of the rubber capsule is fixed in the sealing groove 8 at the bottom inside the tank body, and the flange at the top of the rubber capsule is fixed in the sealing groove 8 at the top of the tank body Inside, so that the fuel is sealed in the rubber capsule, so that the fuel is not filled between the rubber capsule and the tank body;

[0026] The tank body is provided with a gas nozzle, through which the inert...

Embodiment 2

[0039] The designed tank body 2 has a diameter of The total length is 1800mm, and the material is glass fiber / epoxy composite material. The wall thickness of the storage tank is 8mm. The outer wall of the storage tank is provided with an air nozzle 5 . The air nozzle and the box are sealed by epoxy bonding. The sealing groove 8 on the bottom end of the storage tank and the opening end face is 5mm (wide) * 4mm (deep). The sealing parts of the flanges of the corresponding rubber capsules 3 have a height of 6 mm, a width of 3 mm, and a rectangular shape. The material of the rubber capsule 3 is neoprene, the tensile strength is ≥13MPa, and the elongation at break is ≥180%. The rest of the rubber capsule 3 is designed and prepared according to the shape of the tank, and the thickness of the capsule 3 is 3mm. Plug the rectangular sealing parts at both ends of the capsule body 3 into the corresponding sealing grooves of the box respectively. The pipe body 1 is made of composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com