Carbon fiber honeycomb structure and preparation method thereof

A technology of honeycomb structure and carbon fiber, which is applied in the preparation of carbon fiber honeycomb structure and the field of carbon fiber honeycomb structure, can solve the problems of single tube forming and bonding with heavy workload and complex process, and achieve obvious buffering and energy absorption effect and good impact resistance , the effect of high specific strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Attached below figure 1 to attach Figure 5 The present invention is described further:

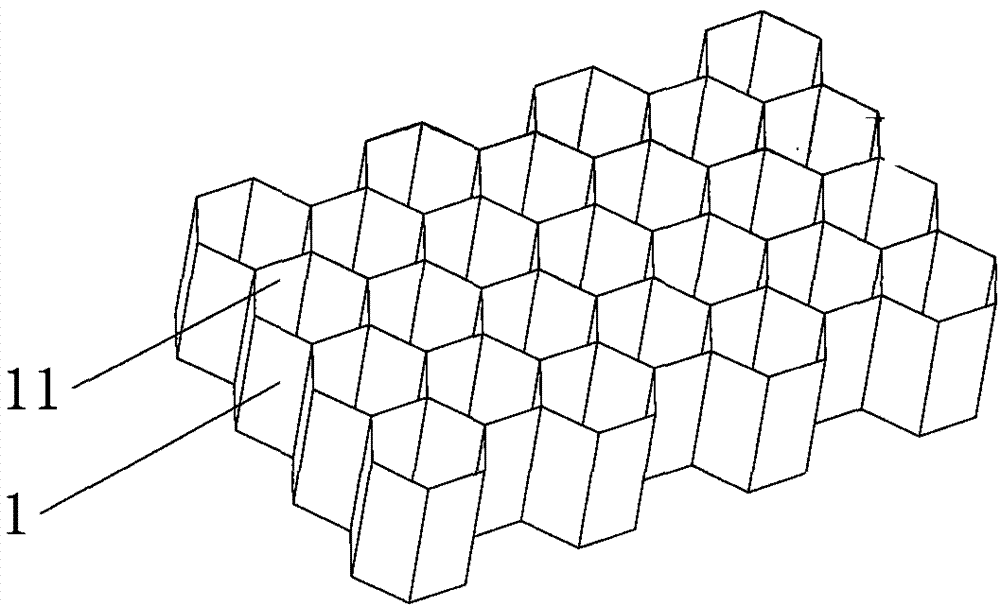

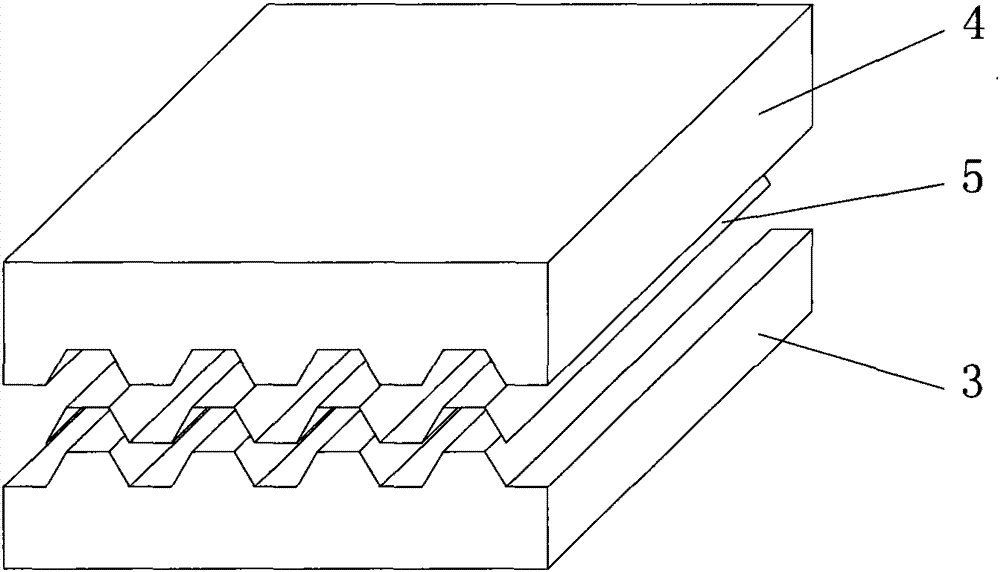

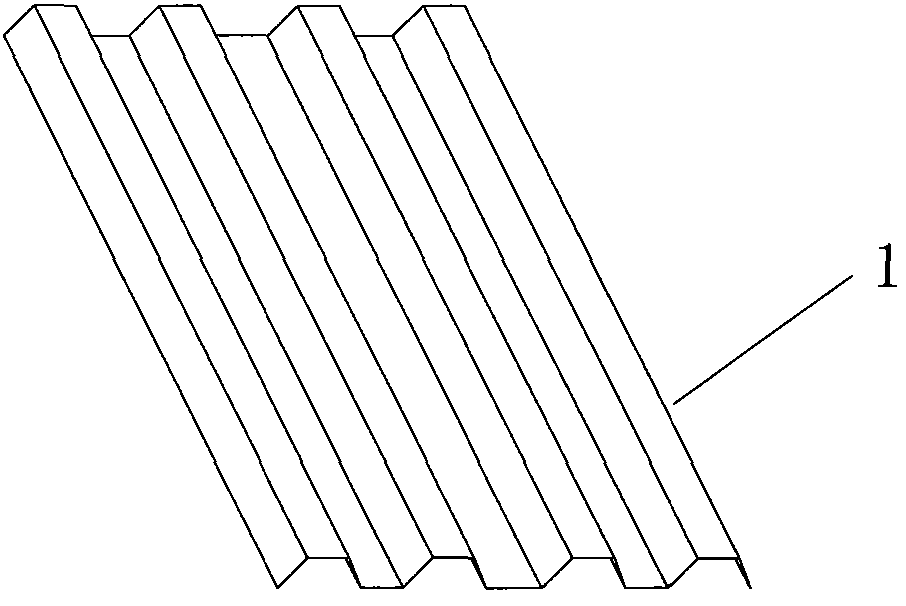

[0034] Such as Figure 1 to Figure 3 The shown carbon fiber honeycomb structure includes a plurality of honeycomb sub-pieces 1 having a continuous semi-hexagonal shape, and the plurality of honeycomb sub-pieces 1 are arranged in sequence and coated with epoxy resin at the overlapping bonding surfaces 11 Adhesives or adhesive films, fixed and bonded to form a hexagonal honeycomb structure in cross section, in the present invention, the honeycomb sub-part 1 adopts carbon fiber prepreg with a carbon content of more than 90% and heats it through the autoclave process or molded.

[0035] The carbon fiber honeycomb structure of the present invention is prepared by the preparation method:

[0036] Preparation method one:

[0037] The autoclave process that this preparation method adopts comprises the following steps:

[0038] Step S1: Cut the calculated carbon fiber prepreg into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com