Preparation method of surface amino-group functionalization SBA-15 mesoporous silica

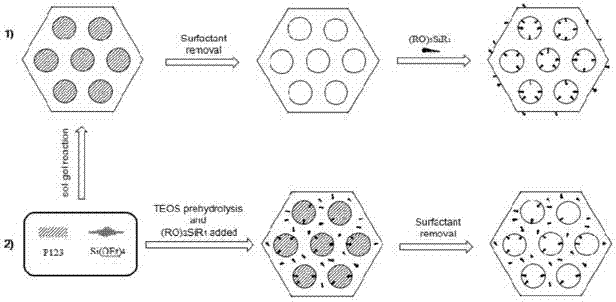

A technology of mesoporous silica and amino functional group, which is applied in the preparation of silica and amino compounds, and the preparation of organic compounds, etc., can solve the problems of poor material morphology, uneven distribution, and embedding of functional groups, and achieve rich The effect of method type, uniform pore size distribution and high hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

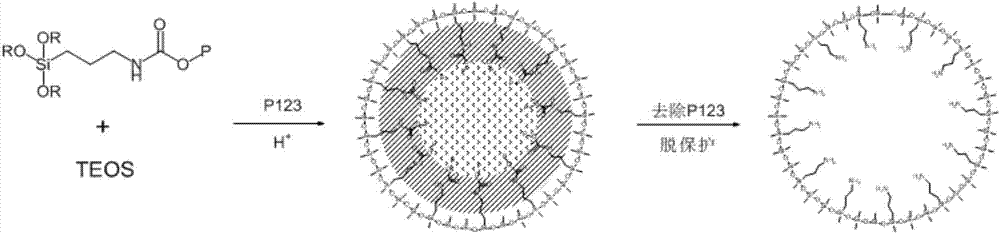

[0033] (1) Synthesis of amino functional precursor protected by 2-naphthol (Np): Dissolve Np (1.44g, 10mmol) in 30mL anhydrous THF under nitrogen protection, add ICPTES (1.28mL, 5mmol), triethylamine (10mmol); Heating at 60°C for 24h, TLC detects that there is no raw material point, reclaims the solvent, and the resulting solid is recrystallized with n-hexane to obtain the precursor Np-Si; the reaction of the preparation of the 2-naphthol-protected amino functional precursor in this step The formula is as follows:

[0034]

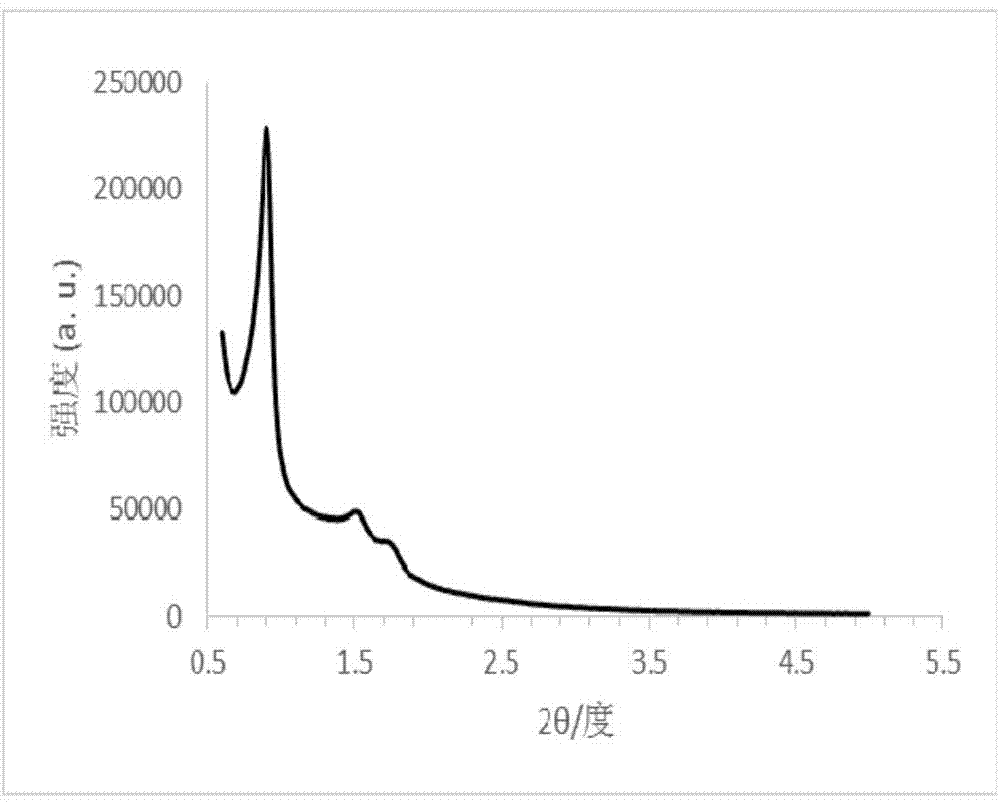

[0035] (2) Synthesis of mesoporous silica material: at room temperature, P123 (1.85g, 0.32mmol) was dissolved in 3mol / L hydrochloric acid aqueous solution, wherein the molar ratio of acid, deionized water and structure directing agent was: 11.5 / 210 / 0.016, stirred for 2h to obtain a clear and transparent solution A. Weigh Np-Si (1.833g, 5mmol, accounting for 20% of the total silicon source) and dissolve it with 1mL THF to obtain solution B. At 40°C, add...

Embodiment 2

[0040] (1) Synthesis of functional precursors protected by phenol (Ph): under the protection of argon, dissolve Ph (0.94g, 10mmol) in 20mL of anhydrous toluene, add ICPTES (2.55mL, 10mmol), dilauric acid Dibutyltin (5 mmol). Heat at 60°C for 18 hours, TLC detects no raw material point, recover the solvent, and purify the obtained solid through a silica gel column to obtain the precursor Ph-Si; the reaction formula for the preparation of the phenol-protected amino functional precursor in this step is as follows:

[0041]

[0042] (2) Synthesis of mesoporous silica material: at room temperature, P123 (1.2g, 0.2mmol) was dissolved in 3mol / L nitric acid aqueous solution, wherein the molar ratio of acid, deionized water and structure directing agent was: 11.5 / 210 / 0.020, stir until a clear and transparent solution A is obtained. Weighed Ph-Si (0.213g, 0.67mmol) and dissolved it in 1mL THF to obtain solution B, and added solution B dropwise to rapidly stirring solution A at 35°C....

Embodiment 3

[0047] (1) Synthesis of 4-benzylphenol (Bp)-protected amino functional precursor: under nitrogen protection, Bp (1.84g, 10mmol) was dissolved in 30mL of anhydrous chloroform, and ICPTES (3.82mL, 15mmol) was added, 50 mmol piperidine. Heat at 60°C for 24 hours, TLC detects no raw material point, recover the solvent, and recrystallize the obtained solid with n-hexane to obtain the precursor Bp-Si; the reaction formula for the preparation of the 4-benzylphenol-protected amino functional precursor in this step is as follows:

[0048]

[0049] (2) Synthesis of mesoporous silica material: Dissolve P123 (0.93g, 0.16mmol) in 3mol / L sulfuric acid solution at room temperature, wherein the molar ratio of acid, deionized water and structure directing agent is: 11.5 / 210 / 0.020, stirred until clear and transparent to obtain solution A. Weighed Bp-Si (0.431g, 1.00mmol) and dissolved it in 1mL THF to obtain solution B, and added solution B dropwise to rapidly stirred solution A at 45°C. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com