Modified molecular sieve catalyst for piperidine preparation, preparation method and applications thereof

A molecular sieve and catalyst technology, which is applied in the field of modified molecular sieve catalysts, can solve the problems of no large-scale industrial production, difficulties in product refining and recycling, and expensive catalysts, so as to suppress high-boiling point by-products, improve catalytic activity, and reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

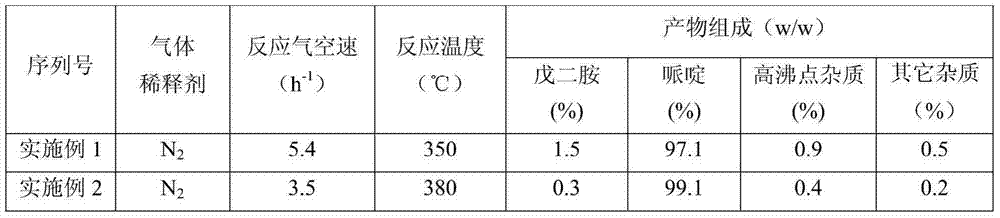

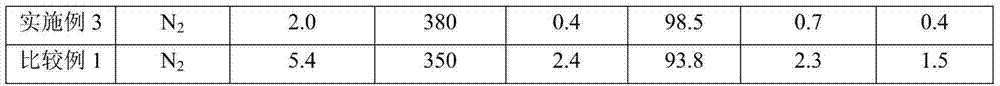

Embodiment 1

[0051] Weigh Fe(NO 3 ) 3 9H 2 O (60.60g, 150.0mmol), Mn (NO 3 ) 2 4H 2 O (2.01g, 8.0mmol), Ca (NO 3 ) 2 .4H 2 O (1.53g, 6.5mmol) and KNO 3 (0.08g, 0.8mmol) in the beaker (wherein the mass percent of metal catalyst in the modified molecular sieve catalyst is 4.95%), add 1000ML deionized water, stirring and dissolving makes aqueous solution, this aqueous solution is poured into molecular sieve carrier ( Wherein, mass percentage HZSM-5 molecular sieve 40%, binder alumina 60%; In the beaker that the silicon-aluminum molar ratio of HZSM-5 molecular sieve is 100), stir, impregnate 24 hours, after drying at 130 ℃, grind 60 Mesh sieve, mechanically formed into spherical shape, put into muffle furnace and bake at 550°C for 4 hours, take it out and cool in desiccator to make 20-mesh solid particles to obtain modified molecular sieve catalyst.

[0052] Get about 100ml of the above-mentioned modified molecular sieve catalyst and pack it into a stainless steel reactor. The catalys...

Embodiment 2

[0055] Weigh Fe(NO 3 ) 3 9H 2 O (48.48g, 120.0mmol), Ba(NO 3 ) 2 (2.35g, 9.0mmol), Zr(NO 3 ) 4 ·5H 2 O (0.86g, 2.0mmol) and KNO3 (0.08g, 0.8mmol) in the beaker (wherein the mass percent of metal catalyst in the modified molecular sieve catalyst is 4.16%), add 1000ML deionized water, stirring and dissolving makes aqueous solution, Pour the aqueous solution into a beaker equipped with a molecular sieve carrier (wherein, the mass percent HZSM-5 molecular sieve is 40%, the binder alumina is 60%; the silicon-aluminum molar ratio of the HZSM-5 molecular sieve is 100), stirred, and soaked for 24 hours , after drying at 130°C, grind through a 60-mesh sieve, mechanically form a ball, put it into a muffle furnace and bake at 550°C for 4 hours, take it out and cool it in a desiccator, and make 20-mesh solid particles to obtain a modified molecular sieve catalyst .

[0056] Get about 100ML of the modified molecular sieve catalyst and put it into a stainless steel reactor. The cata...

Embodiment 3

[0059] Weigh Fe(NO 3 ) 3 9H 2 O (48.48g, 120.0mmol), Ba(NO 3 ) 2 (2.09g, 8.0mmol), Ga(NO 3 ) 3 (0.51g, 2.0mmol), Ce(NO 3 ) 4 (0.31g, 0.8mmol) and NaNO 3 (0.03g, 0.3mmol) in the beaker (wherein the mass percent of metal catalyst in the modified molecular sieve catalyst is 4.19%), add 1000ML deionized water, stir and dissolve and obtain aqueous solution, this aqueous solution is poured into molecular sieve carrier ( Wherein mass percent HZSM-5 molecular sieve 40%, binder aluminum oxide 60%; The silicon-aluminum molar ratio of HZSM-5 molecular sieve is 150) in the beaker, stir, impregnate 24 hours, after drying at 130 ℃, grind through 60 mesh sieves , into a spherical shape mechanically, put into a muffle furnace and roast at 550°C for 4 hours, take it out and cool it in a desiccator, and make 20-mesh solid particles to obtain a modified molecular sieve catalyst.

[0060] Get about 100ml of the modified molecular sieve catalyst and pack it into a stainless steel reactor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com