Fundamental transverse mode microcolumn laser based on polymer

A basic transverse mold and polymer technology, applied in the field of lasers, can solve the problems of complex laser production technology, unsuitable for mass production, and high production cost, and achieve the effects of being beneficial to mass production, easy to shape processing, and low processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

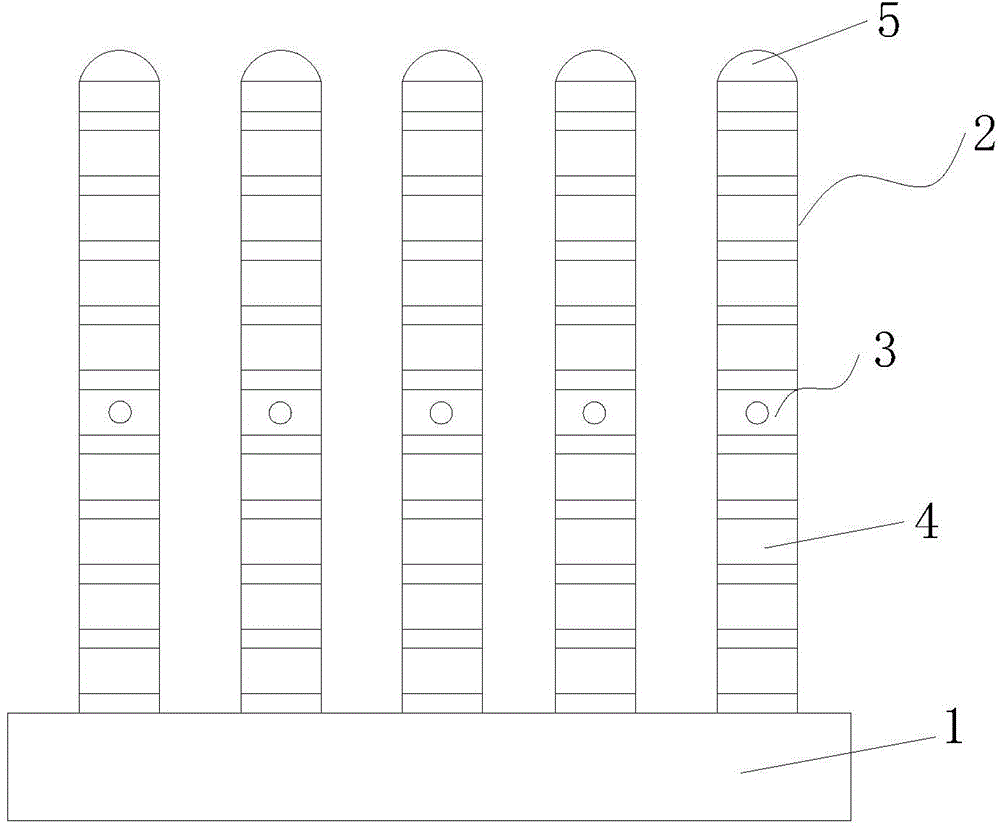

[0030] Such as figure 1 and 2 As shown, a kind of polymer-based fundamental transverse mode micro-cylindrical laser proposed by the present invention includes a base 1 and a plurality of micro-cylindrical optical units 2, wherein:

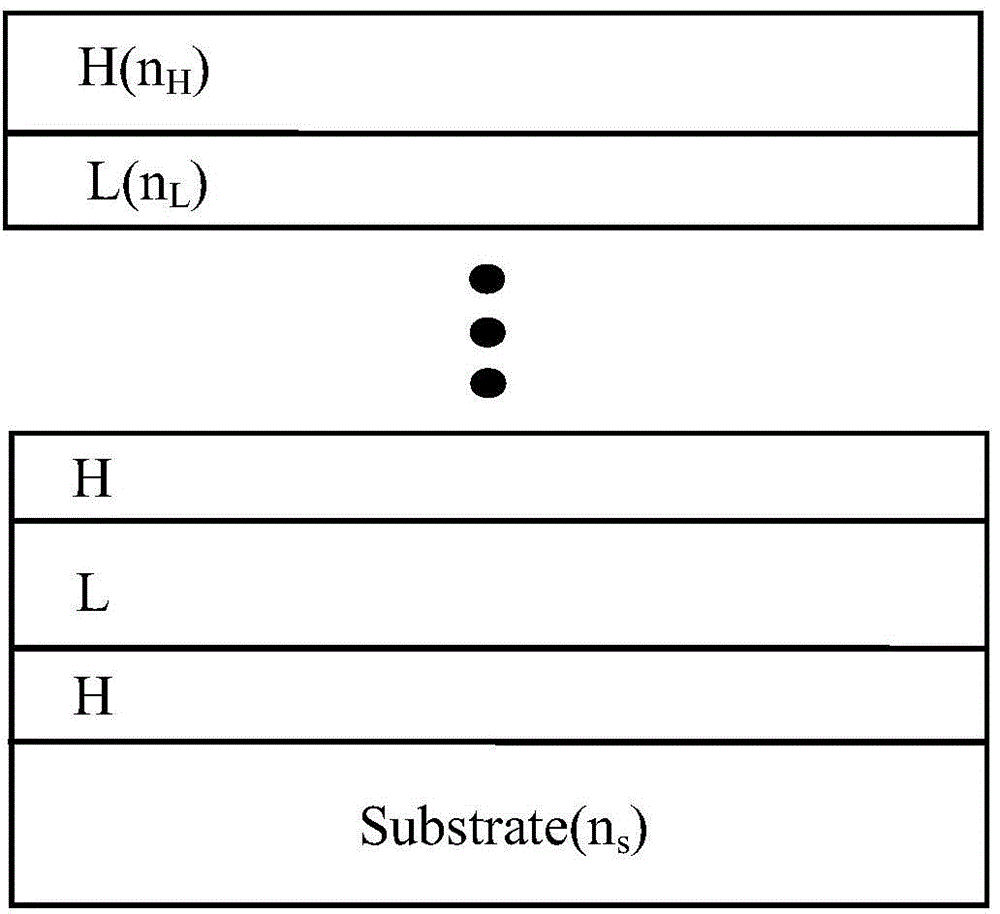

[0031] The optical units 2 are distributed in an array, and can be used in parallel optical transmission systems, optical interconnection networks of parallel processing computer cluster systems, and ultra-small high-performance optical interconnection parallel multiprocessor systems in space-borne free space. The optical unit 2 includes two distributed Bragg reflectors 4, a resonant cavity 3 sandwiched between the two distributed Bragg reflectors 4, and the distributed Bragg reflector 4 has two polymers with different refractive indices A periodic structure formed by alternating thin films; the resonant cavity 3 is made of an organic semiconductor or a single-layer polymer film doped with an active medium, and among the two distributed Bragg refl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com