Cantilever type tunneler whole machine test device

A technology for a tunnel boring machine and a test device, applied in the field of construction machinery, can solve the problems of difficulty in finding early failures, cross-sectional size and lifting restrictions, and high service costs, and achieve the advantages of reducing the early failure rate, stable working performance, and reducing test costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

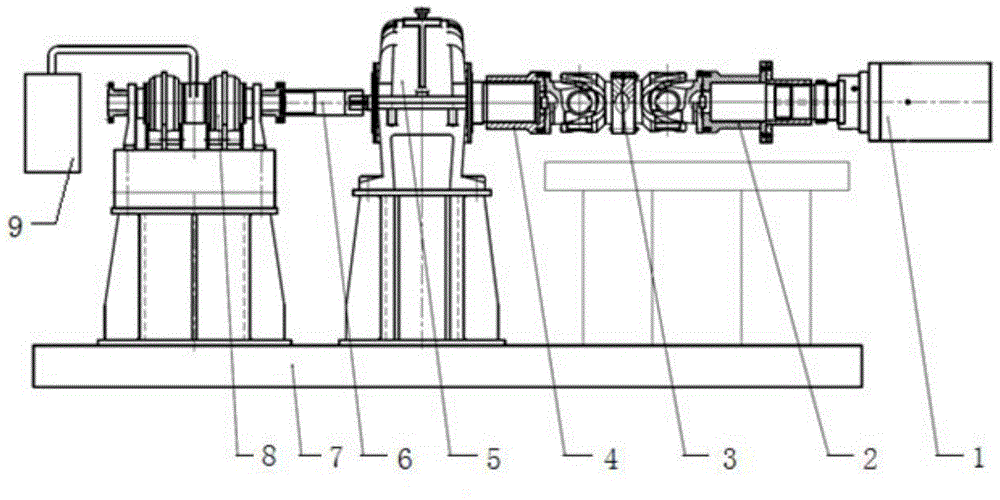

[0018] like figure 1 As shown, a cantilever tunnel boring machine test device includes a base 7, a speed increasing box 5 and a dynamometer 8, a torque speed sensor and a control system 9 fixedly installed on the base 7. The speed increasing box The output drive shaft of 5 is axially connected with the dynamometer 8, and the input drive shaft of the speed-increasing box 5 is covered with a speed-increasing box spline sleeve 4; The box spline sleeve 4 is connected by a universal coupling; the torque and rotational speed sensor is connected with the dynamometer 8 and transmits the measured torque, rotational speed and power signals to the control system 9 . Among them, the dynamometer is used to provide damping torque to test the torque and system stability of the cantilever tunnel boring machine.

[0019] Preferably, the cutting mechanism 1 is connected to the spline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com