Preparation method of SiBN fiber

A fiber and decarbonization technology, which is applied in the direction of fiber chemical characteristics, rayon chemical post-treatment, inorganic raw material rayon, etc., can solve the problems of the negative influence of the spinnability of the precursor, the damage of the fibril structure, and the low content of B elements. , to achieve the effect of improving mechanical properties, improving stability and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Put polycarbosilane non-melting fibers in the decarburization-nitriding system, vacuumize, then replace the gas in the system with nitrogen or argon to normal pressure, repeat at least three times; feed high-purity ammonia, heat up, and heat up system: Raise the temperature to 500°C in 2 hours, raise the temperature to 700°C at 0.95°C / min, keep it for 0.5h, raise the temperature to 800°C in 1h, and keep it for 2h. Cool down to room temperature with nitrogen / argon to obtain highly active Si-N fibers; raise the temperature to 400°C for 2 hours, feed borane into the decarburization-nitridation system for 24 hours, and cool to room temperature with nitrogen / argon; Enter high-purity ammonia gas, raise the temperature, and raise the temperature to 1350°C in 6 hours, and keep it warm for 1-2 hours. Cool to room temperature with nitrogen / argon gas. Serve.

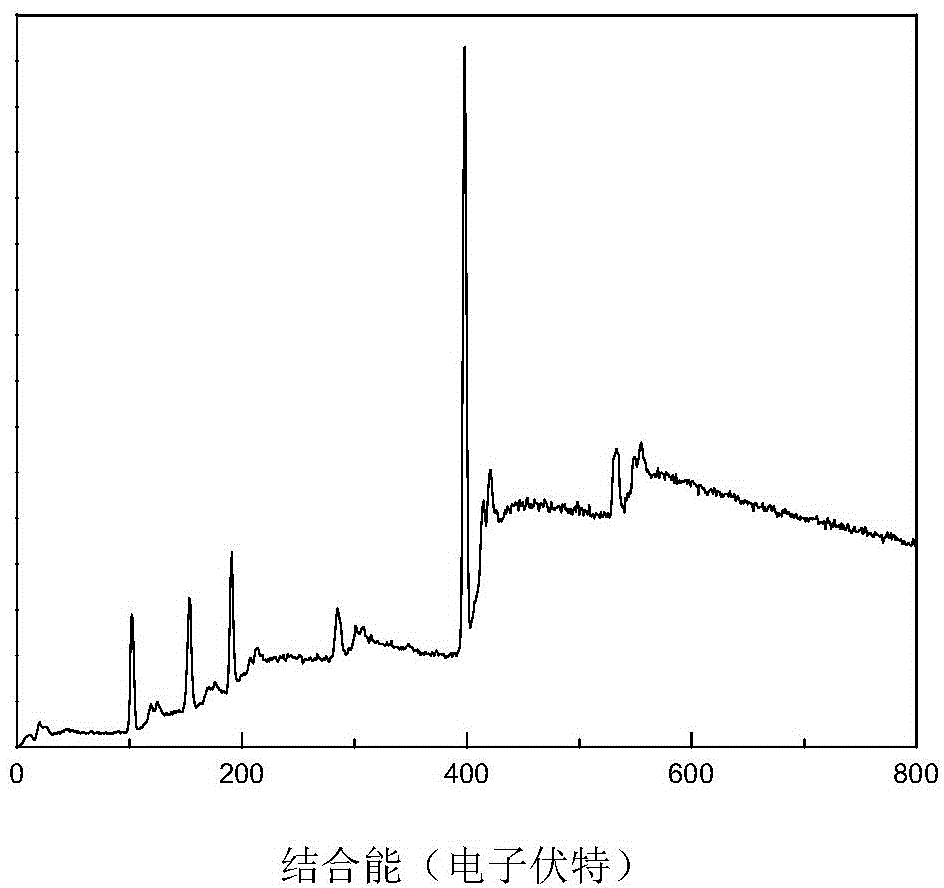

[0038] figure 1 X-ray photoelectron energy map (XPS) for the prepared SiBN fiber. The peak at 100.5 electron volts (eV) ...

Embodiment 2

[0041] Put polycarbosilane non-melting fibers in the decarburization-nitriding system, vacuumize, then replace the gas in the system with nitrogen or argon to normal pressure, repeat at least three times; feed high-purity ammonia, heat up, and heat up system: Raise the temperature to 500°C in 2 hours, then raise the temperature to 700°C at 0.90°C / min, keep it for 0.5h, raise the temperature to 1000°C in 3 hours, and keep it for 1h. Cool down to room temperature with nitrogen / argon to obtain highly active Si-N fibers; raise the temperature to 450°C for 2 hours, pass dimethylborane into the decarburization-nitridation system for 36 hours, and cool with nitrogen / argon to Room temperature; Introduce high-purity ammonia gas, raise the temperature, raise the temperature to 1400°C for 6 hours, and keep it warm for 1 hour. Cool to room temperature with nitrogen / argon gas. Serve.

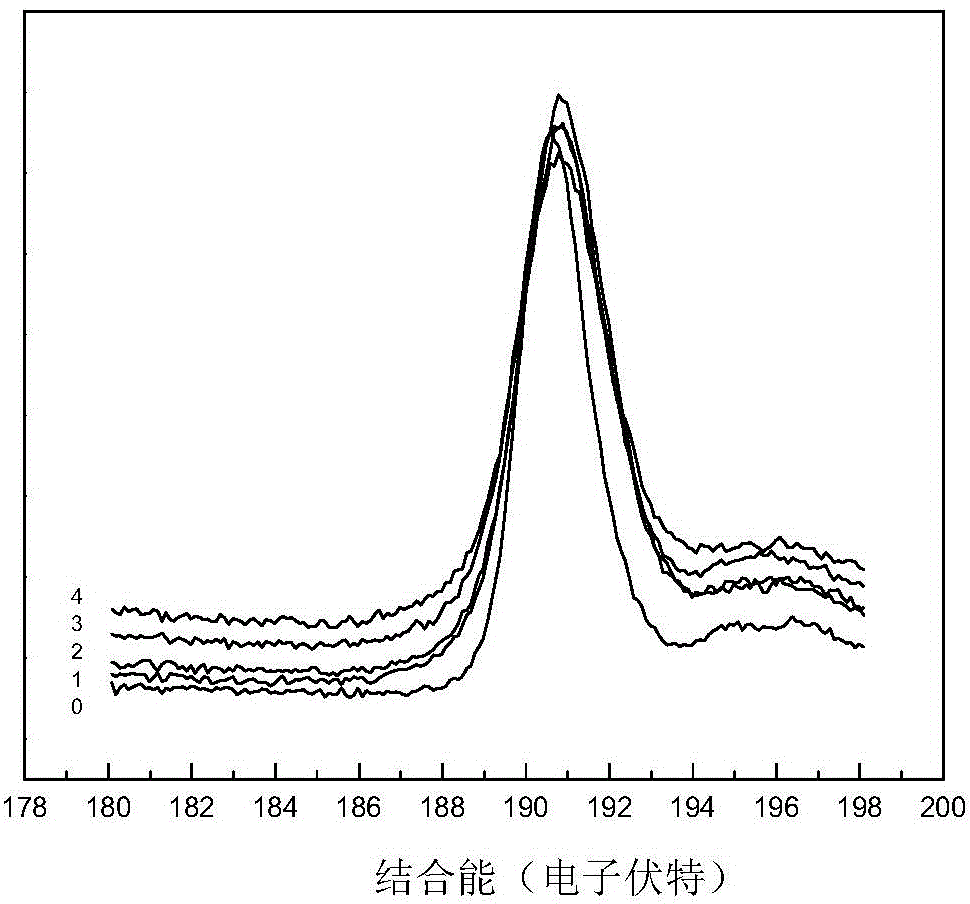

[0042] The X-photoelectron spectrum and radial B element X-ray photoelectron spectrum of the prepared Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com