J55-steel-grade SEW expandable casing tube and manufacturing method thereof

A technology of expansion casing and manufacturing method, which is applied in non-API oil casing, new J55 steel grade SEW expansion casing, alloy design and manufacturing, can solve the problem of inability to ensure weld performance, complex heat treatment process, and unfavorable scale Problems such as production and product promotion, to achieve the effect of uniform deformation performance of the economy as a whole, avoiding energy consumption and cost increase, and broad-scale application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The chemical composition of the hot-rolled steel coil in this embodiment is (mass percentage, %): C 0.06, Si 0.22, Mn 1.16, Cr 1.07, B 0.0008, P 0.014, S 0.004, and the balance is Fe.

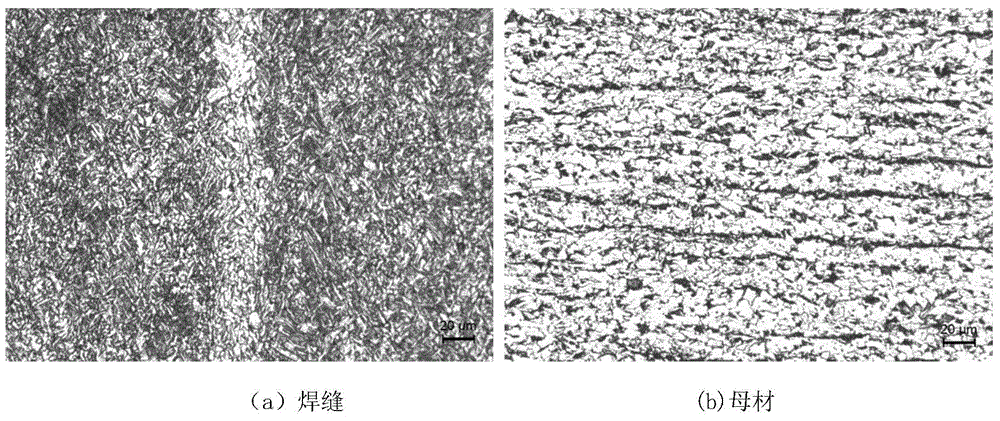

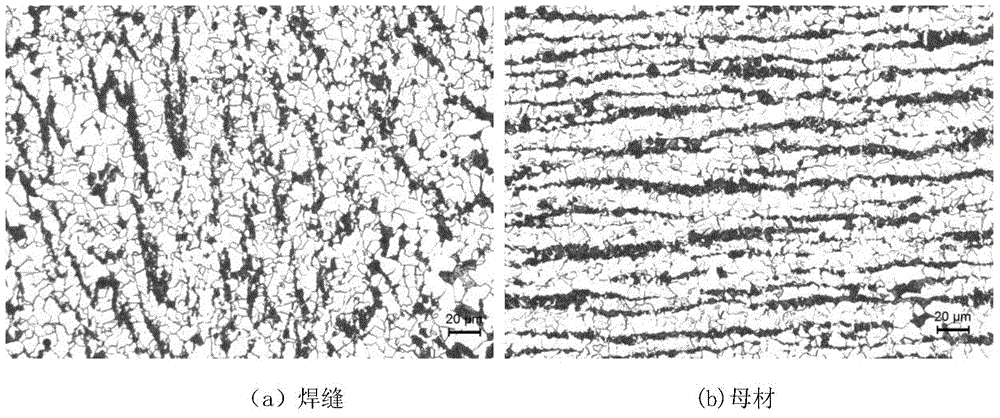

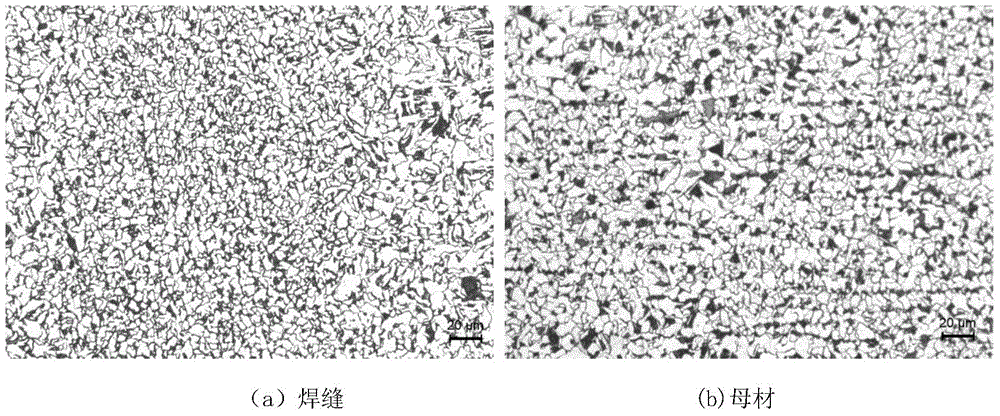

[0017] The production steps are as follows: First, the hot-rolled steel coil with the above composition is subjected to slitting, edge milling, roll forming and high-frequency resistance welding to make a welded parent pipe with an outer diameter of Φ193.7mm and a wall thickness of 7.8mm; secondly , the HFW welded parent pipe is rapidly heated to 1010°C by an intermediate frequency induction heating furnace, and then enters the multi-roller unit for thermal tension reduction of the entire pipe body, and a thermally reduced pipe with an outer diameter of Φ139.7mm and a wall thickness of 8.15mm is obtained. billet; finally, the heat-stretched and reduced tube billet, which is still at a high temperature of about 825°C, is quickly cooled to 360°C by an on-line control cooling device, and the...

Embodiment 2

[0020]The chemical composition of the hot-rolled steel coil in this embodiment is (mass percentage, %): C 0.11, Si 0.17, Mn 1.12, Cr 0.52, B 0.0011, P 0.008, S 0.002, and the balance is Fe.

[0021] The production steps are as follows: First, the hot-rolled steel coil with the above composition is subjected to slitting, edge milling, roll forming and high-frequency resistance welding to make a welded parent pipe with an outer diameter of Φ193.7mm and a wall thickness of 7.34mm; secondly , the HFW welded main pipe is rapidly heated to 995°C by an intermediate frequency induction heating furnace, and then enters the multi-roller unit for thermal tension reduction of the entire pipe body, and a thermally reduced pipe with an outer diameter of Φ139.7mm and a wall thickness of 7.72mm is obtained. Billet; finally, the heat-stretched and reduced tube billet, which is still at a high temperature of about 810°C, is quickly cooled to 390°C by an on-line control cooling device, and then a...

Embodiment 3

[0024] The chemical composition of the hot-rolled steel coil in this embodiment is (mass percentage, %): C 0.18, Si 0.25, Mn 1.28, Cr 0.31, B 0.0006, P 0.005, S 0.002, and the balance is Fe.

[0025] The production steps are as follows: First, the hot-rolled steel coil with the above composition is subjected to slitting, edge milling, roll forming and high-frequency resistance welding to make a welded parent pipe with an outer diameter of Φ193.7mm and a wall thickness of 7.9mm; secondly , the HFW welded parent pipe is rapidly heated to 980°C by an intermediate frequency induction heating furnace, and then enters the multi-roller unit for thermal tension reduction of the entire pipe body, and a thermally reduced pipe with an outer diameter of Φ139.7mm and a wall thickness of 8.38mm is obtained. Billet; finally, the heat-stretched and reduced tube billet, which is still at a high temperature of about 795°C, is rotated through the online control cooling device to be rapidly cooled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com