High-conductivity heat-resistance aluminum alloy wire and preparation method thereof

An aluminum alloy wire, high electrical conductivity technology, applied in the direction of metal/alloy conductors, etc., can solve the problems of high energy consumption and low electrical conductivity, and achieve the effect of reducing line loss, good electrical conductivity, and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

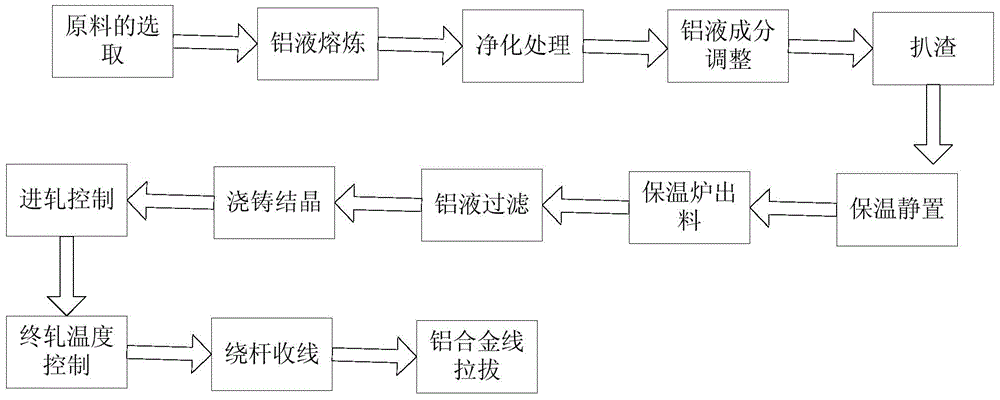

Image

Examples

Embodiment 1

[0026] Material selection: 6000kg of Al99.70 aluminum ingot is selected for aluminum ingot, and the mass percentage of each element is: Si 0.065%; Fe 0.18%; Ti+Mn+Cr+V 0.018%; The mass percentage is: Zr 4.53%; Fe 0.4%; Si 0.2%; Ti+Mn+Cr+V 0.18% aluminum-zirconium alloy, the aluminum-iron alloy is selected as 15kg, and the mass percentage of each element is: Fe 4.92%; Si 0.19%; Ti+Mn+Cr+V 0.033% aluminum-iron alloy; aluminum-silicon alloy 18kg, the mass percentage of each element is: Si 9.84%; Fe 0.18%; Ti+Mn+Cr+V 0.049% aluminum-silicon alloy; aluminum ytterbium Alloy selection 40kg, the mass percentage of each element is: Yb 9.85%; Si 0.2%; Fe 0.25% aluminum ytterbium alloy; aluminum boron alloy selection 35kg, the mass percentage of each element is: B 2.97%; Si 0.19%; Fe 0.24 % aluminum boron alloy.

[0027] Mix the weighed aluminum ingots, aluminum-iron alloys, and aluminum-silicon alloys evenly into the melting furnace for melting; when the molten aluminum flows out of th...

Embodiment 2

[0029]Material selection: 7000kg aluminum ingot with grade Al99.70 is selected for the aluminum ingot, the mass percentage of each element is: Si-0.043%; Fe 0.14%; Ti+Mn+Cr+V 0.015%; aluminum-zirconium alloy is selected 95kg, the The mass percentage is: Zr 4.55%; Fe 0.4%; Si 0.2%; Ti+Mn+Cr+V 0.18% aluminum-zirconium alloy, the aluminum-iron alloy is 55kg, and the mass percentage of each element is: Fe 4.95%; Si 0.19%; Ti+Mn+Cr+V 0.030% aluminum-iron alloy; aluminum-silicon alloy 18kg, the mass percentage of each element is: Si 9.98%; Fe 0.2%; Ti+Mn+Cr+V 0.068% aluminum-silicon alloy; aluminum ytterbium The alloy is 85kg, and the mass percentage of each element is: Yb 9.76%; Si 0.2%; Fe 0.24% aluminum ytterbium alloy; the aluminum boron alloy is 90kg, and the mass percentage of each element is: B 2.97%; Si 0.19%; Fe 0.24 % aluminum boron alloy.

[0030] Aluminum ingots, aluminum-iron alloys, and aluminum-silicon alloys are evenly matched in proportion to the melting furnace fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com