A kind of multi-band laser protection transparent ceramic material and preparation method thereof

A technology for transparent ceramics and laser protection, applied in multi-band laser protection transparent ceramic materials and their preparation, in the field of high-energy blinding laser protection, can solve the problems of poor chemical stability, limited use range, difficult to control dispersion, etc. Simple process, overcoming the problem of component segregation, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

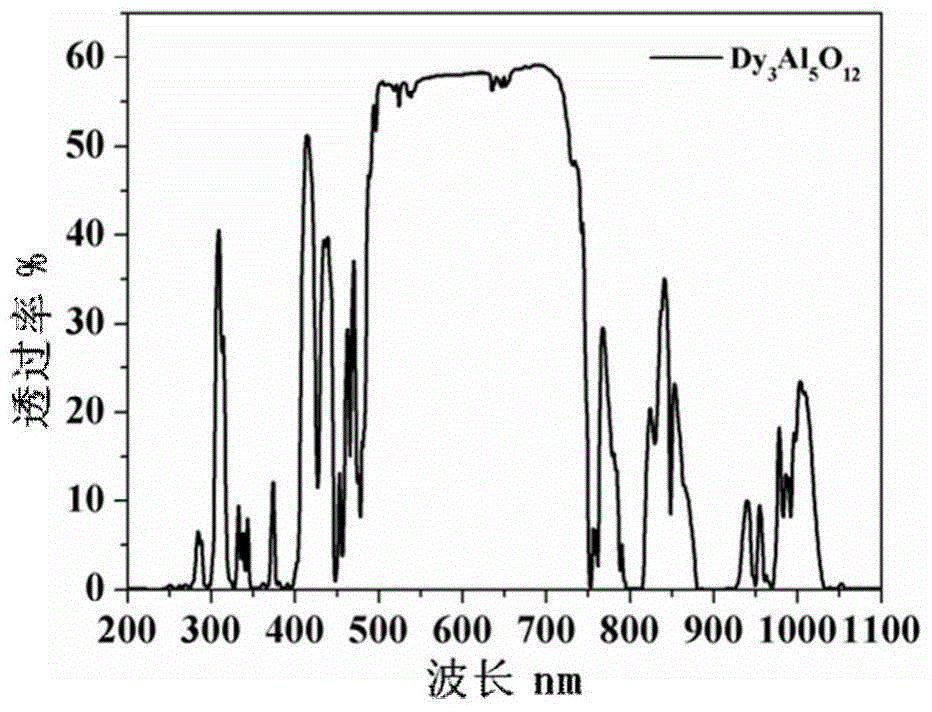

Embodiment 1

[0025] A kind of anti-laser material of the present invention, according to Dy 3 Al 5 o 12 The general chemical formula, accurately weigh α-Al 2 o 3 12.2352g, Dy 2 o 3 26.8560g, and add 0.0390g of MgO powder and 0.1955g of high-purity TEOS reagent as composite sintering aids, and use a planetary mill for thorough mixing. The ball-milled slurry was dried in a constant temperature oven at 60° C. for 24 hours, then ground and passed through a 200-mesh sieve. Weigh 7.5 g of the ground ceramic powder, and perform cold isostatic pressing after pre-pressing at a pressure of 300 MPa to obtain a dense green body. The green body is sintered by vacuum reaction technology, heated to 1840 ° C, kept for 10 hours, and the vacuum degree is 10 -3 Pa. After cooling with the furnace, it is annealed in an annealing furnace at 1540 ° C for 10 hours. After double-sided polishing, high-quality transparent ceramics are obtained. The transparent ceramic has an absorption rate of more than 99...

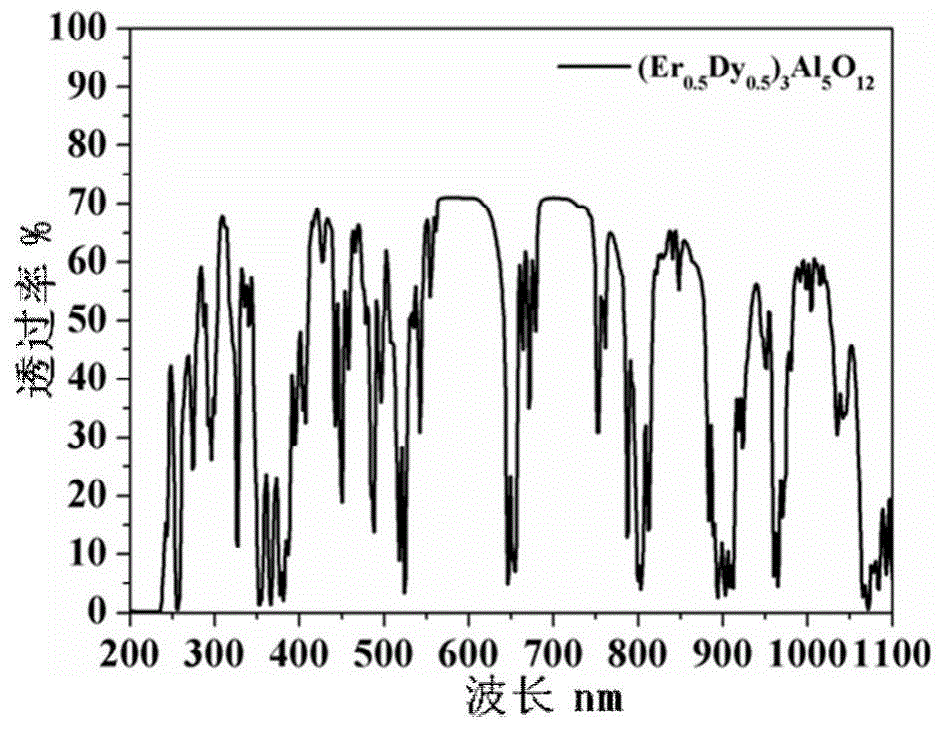

Embodiment 2

[0027] A kind of dual-band laser protective transparent ceramic material of the present invention, according to (Er 0.5 Dy 0.5 ) 3 Al 5 o 12 The general chemical formula, accurately weigh α-Al 2 o 3 3.5686g, Dy 2 o 3 3.9165g, Er 2 o 3 4.0165g, and add 0.0035g MgO powder and 0.0920g high-purity TEOS reagent as a composite sintering aid, and use a planetary mill to fully mix after blending. The ball-milled slurry was dried in a constant temperature oven at 60° C. for 24 hours, then ground and passed through a 200-mesh sieve. Weigh 2 g of the ground ceramic powder, and perform cold isostatic pressing after pre-pressing at a pressure of 150 MPa to obtain a dense green body. The green body is sintered by vacuum reaction technology, heated to 1780 ° C, kept for 6 hours, and the vacuum degree is 10 -4 Pa. After cooling with the furnace, it was annealed in a 1450°C annealing furnace for 4 hours. After double-sided polishing, high-quality transparent ceramics are obtained....

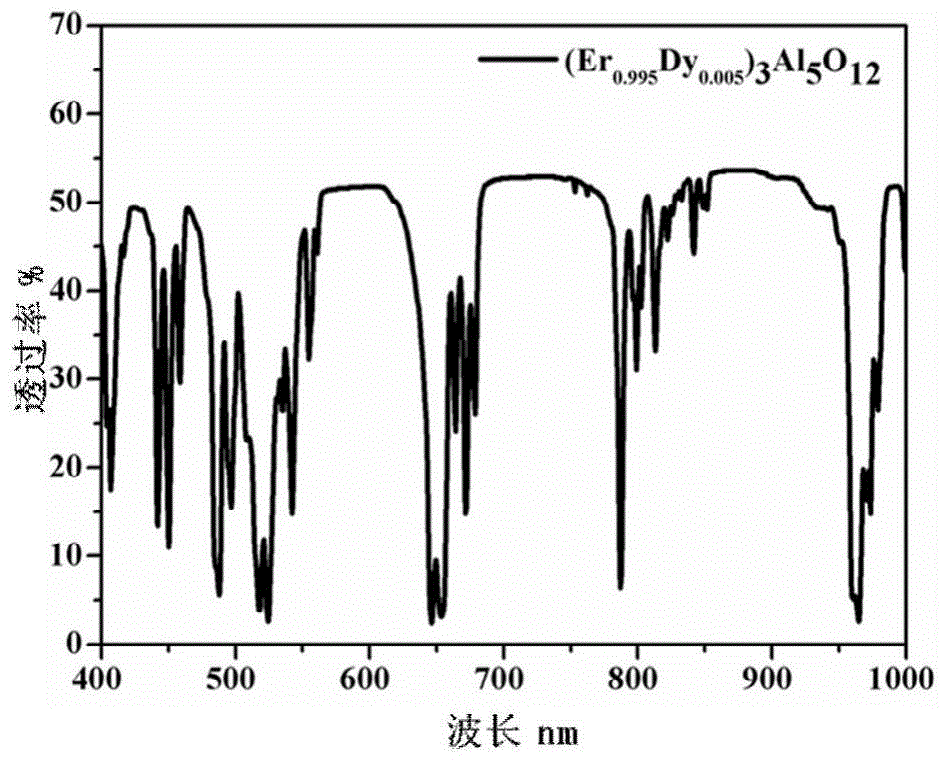

Embodiment 3

[0029] A kind of dual-band laser protective transparent ceramic material of the present invention, according to (Er 0.995 Dy 0.005 ) 3 Al 5 o 12 The general chemical formula, accurately weigh α-Al 2 o 3 10.1960g, Er 2 o 3 22.8364g, Dy 2 o3 0.1119g, and add 0.0165g MgO powder and 0.1988g high-purity TEOS reagent as a composite sintering aid, and use a planetary mill to fully mix after blending. The ball-milled slurry was dried in a constant temperature oven at 60° C. for 24 hours, then ground and passed through a 200-mesh sieve. Weigh 4 g of the ground ceramic powder, pre-press and then perform cold isostatic pressing at a pressure of 200 MPa to obtain a dense green body. The green body is sintered by vacuum reaction technology, heated to 1720 ° C, kept for 12 hours, and the vacuum degree is 10 -4 Pa. After cooling with the furnace, it was annealed in a 1400°C annealing furnace for 5 hours. After double-sided polishing, high-quality transparent ceramics are obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com