Method for rear wall protection in laser processing of turbine blade by using water and silicon dioxide

A silicon dioxide and turbine blade technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of complex preparation process, easy agglomeration of nanoparticles, affecting the use of turbine blades, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

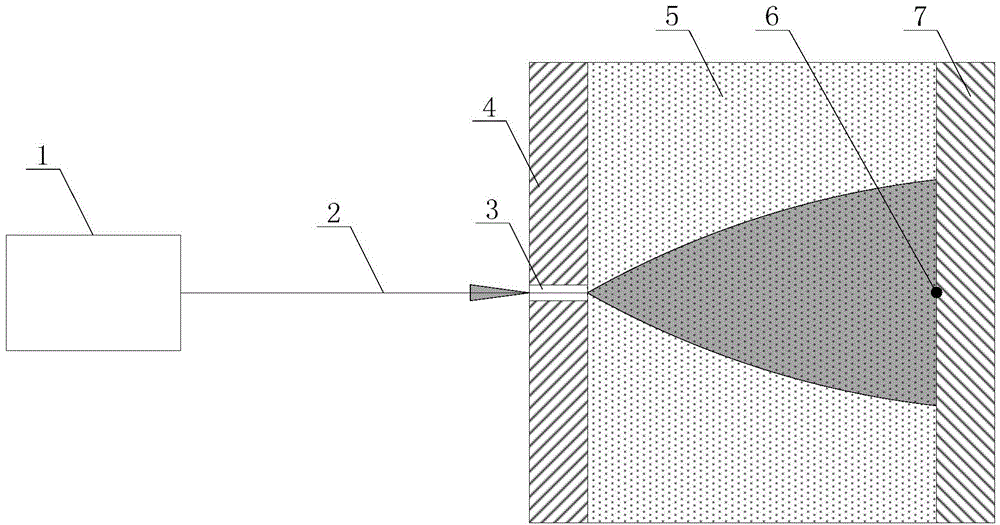

Method used

Image

Examples

Embodiment 1

[0020] Water-silicon dioxide is used as the rear wall protection method in the laser processing of turbine blades, including the following steps:

[0021] 1) Grinding the silica and sieving with a standard test sieve, the particle size range of the final silica particles used is: 1.3 μm to 38 μm;

[0022] 2) mixing silicon dioxide with water to make a paste, wherein the mass fraction of silicon dioxide is 90.9%, and then pouring the paste into the blade flow channel through the hole at the top of the turbine blade;

[0023] 3) Using pulsed laser drilling, the process parameters of pulsed laser drilling are: frequency 70Hz, pulse width 0.2ms, peak power 16KW;

[0024] 4) After drilling the holes, use running water to pass through the holes at the top of the turbine blades to flush out the silicon dioxide particles in the flow channel. After the silicon dioxide particles are completely washed out, dry them with hot air.

[0025] The beneficial effect of this embodiment:

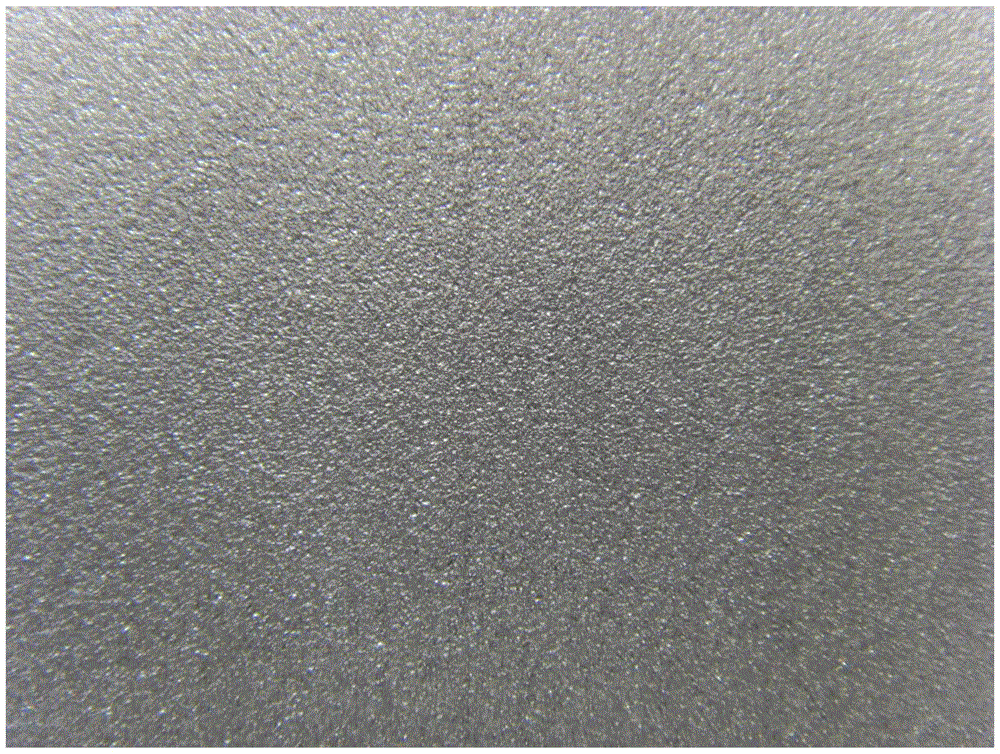

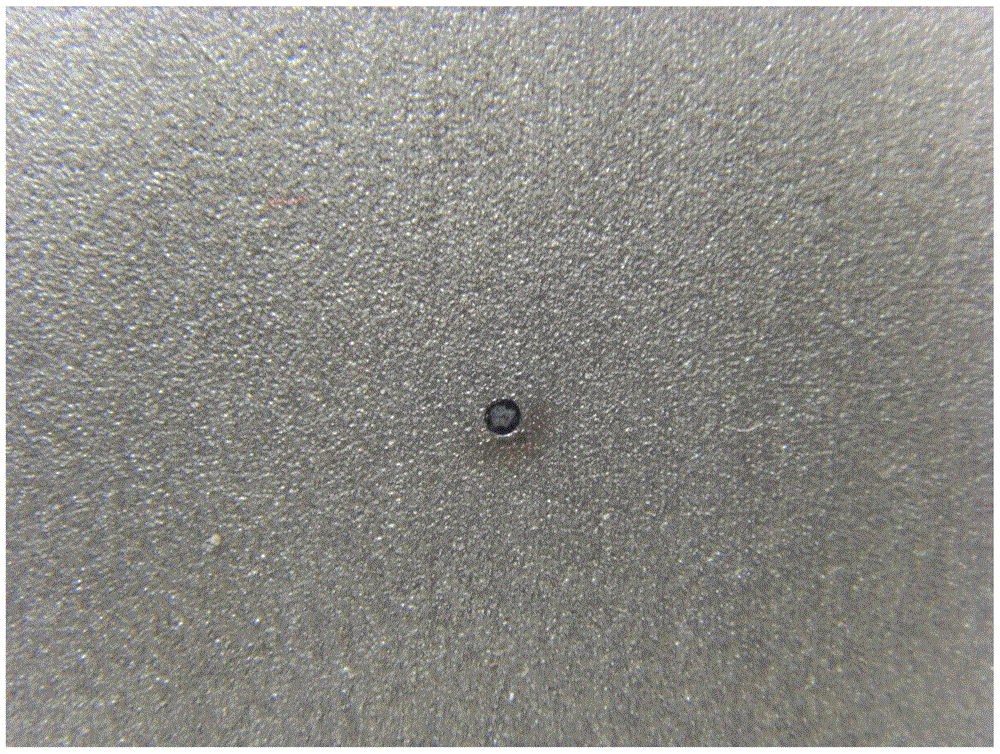

[002...

Embodiment 2

[0028] Water-silicon dioxide is used as the rear wall protection method in the laser processing of turbine blades, including the following steps:

[0029] 1) Grinding the silica and sieving with a standard test sieve, the particle size range of the final silica particles used is: 38 μm to 74 μm;

[0030] 2) mixing silicon dioxide with water to make a paste, wherein the mass fraction of silicon dioxide is 84.8%, and then pouring the paste into the blade flow channel through the hole at the top of the turbine blade;

[0031] 3) Using pulsed laser drilling, the process parameters of pulsed laser drilling are: frequency 70Hz, pulse width 0.2ms, peak power 16KW;

[0032] 4) After drilling the holes, use running water to pass through the holes at the top of the turbine blades to flush out the silicon dioxide particles in the flow channel. After the silicon dioxide particles are completely washed out, dry them with hot air.

[0033] The beneficial effect of this embodiment:

[0034...

Embodiment 3

[0036] Water-silicon dioxide is used as the rear wall protection method in the laser processing of turbine blades, including the following steps:

[0037] 1) Grinding the silica and sieving with a standard test sieve, the particle size range of the final silica particles used is: 74 μm to 104 μm;

[0038] 2) mixing silicon dioxide with water to make a paste, wherein the mass fraction of silicon dioxide is 79.6%, and then pouring the paste into the blade flow channel through the hole at the top of the turbine blade;

[0039] 3) Using pulsed laser drilling, the process parameters of pulsed laser drilling are: frequency 70Hz, pulse width 0.2ms, peak power 16KW;

[0040] 4) After drilling the holes, use running water to pass through the holes at the top of the turbine blades to flush out the silicon dioxide particles in the flow channel. After the silicon dioxide particles are completely washed out, dry them with hot air.

[0041] The beneficial effect of this embodiment:

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com