A kind of sintering method and sintering tooling of molded hard alloy long pipe fittings

A technology of cemented carbide and sintering method, which is applied in the field of cemented carbide manufacturing to achieve the effect of ensuring the quality of the shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The cemented carbide grade is YG6, and the sintering temperature is 1450°C.

[0040] The shaft sleeve product of cemented carbide has a length of 25.6mm and an inner diameter of 15.2mm.

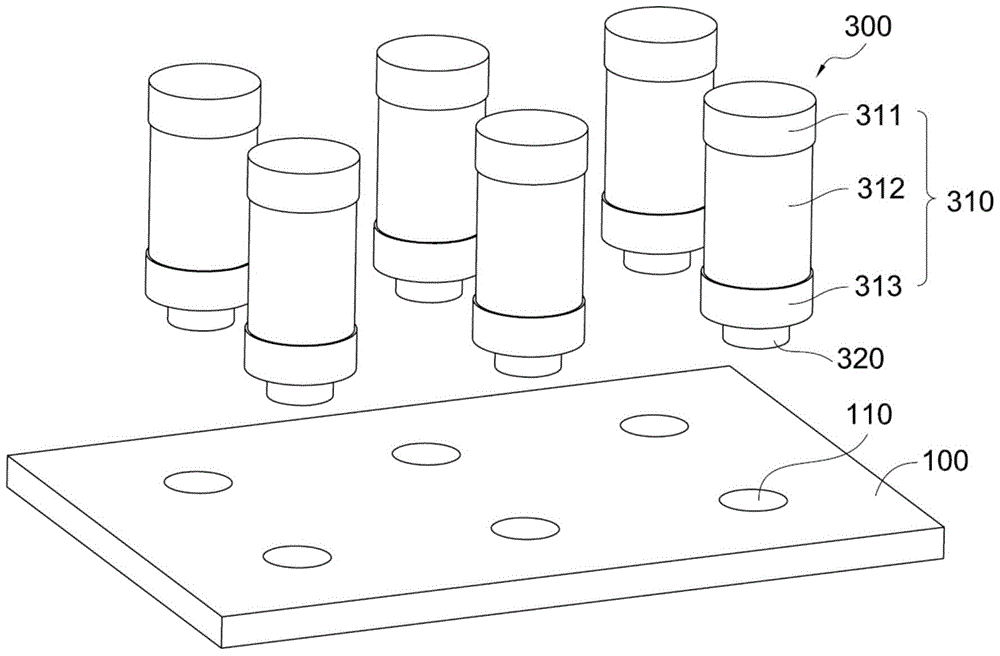

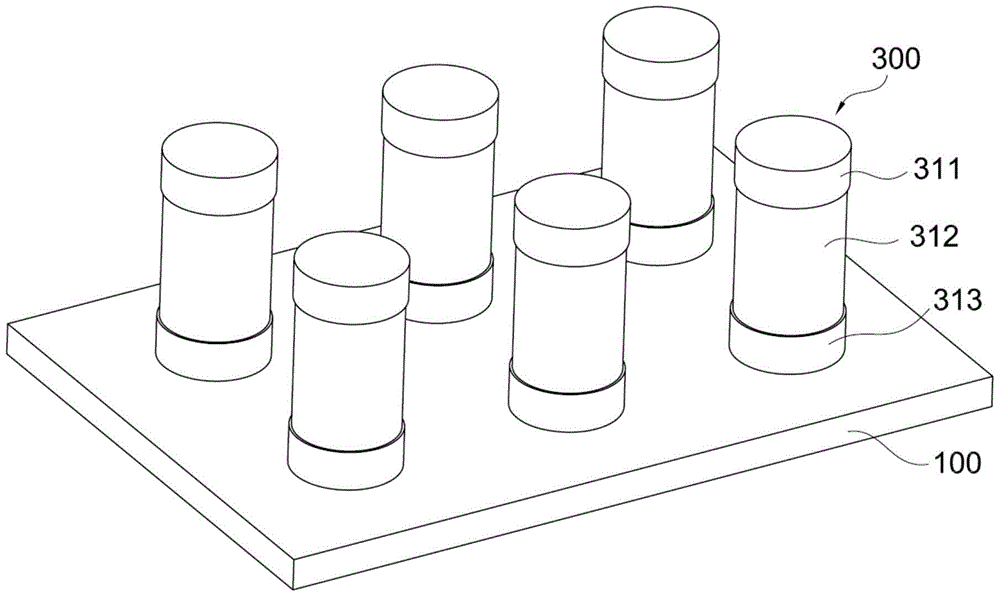

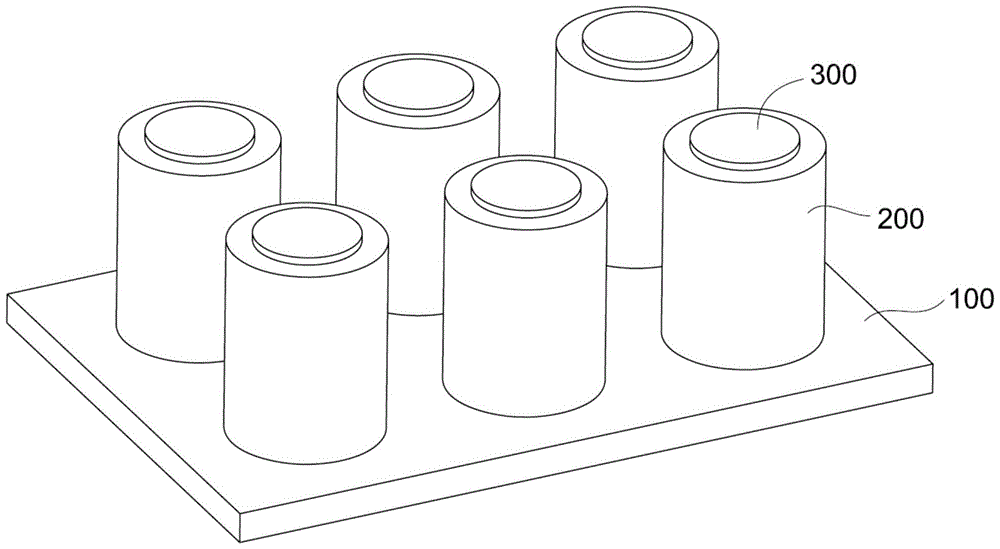

[0041] The graphite boat plate 100 has a thickness of 8 mm.

[0042]Put the YG6 mixture into the mold and carry out two-way pressing according to the conventional pressing process. The height H of the first liner product section 310 is 27mm, and the diameter D of the inner liner parts 311 and 313 is 15.2mm. Put the sintered graphite boat plate 100 into the boat plate support Section 320 has a diameter d of 10mm and a height h of a cylindrical lined graphite core 300 of 7mm. Then the lined product section 310 is ring-cut. The depth S of the groove is 0.4 mm. A through hole with a diameter d1 of 10.3 mm is opened on the sintered graphite boat plate 100 , that is, the graphite core installation hole 110 . Insert the processed boat plate support section 320 lined with the graphite core ...

Embodiment 2

[0044] The cemented carbide grade is YN8, and the sintering temperature is 1450°C.

[0045] The shaft sleeve product of cemented carbide has a length of 52.0mm and an inner diameter of 27.0mm.

[0046] The graphite boat plate 100 has a thickness of 8mm.

[0047] Put the YN8 mixture into the mold and carry out two-way pressing according to the conventional pressing process. The height H of the first liner product section 310 is 54 mm, and the diameter D of the inner liner parts 311 and 313 is 27.0 mm. Put the sintered graphite boat plate 100 into the boat plate support Section 320 has a diameter d of 16 mm and a height h of a cylindrical lined graphite core 300 of 7 mm. Then the lined product section 310 is ring-cut, and the uncut parts at both ends, that is, the length of the inner liner 311, 313 is 10 mm. The depth S of the groove is 0.6 mm. A through hole with a diameter d1 of 16.4 mm is opened on the sintered graphite boat plate 100 , that is, the graphite core installati...

Embodiment 3

[0049] The cemented carbide grade is YG8, and the sintering temperature is 1430°C.

[0050] The shaft sleeve product of cemented carbide has a length of 180.0mm and an inner diameter of 112.0mm.

[0051] The graphite boat plate 100 has a thickness of 8mm.

[0052] Put the YG8 mixture into the mold and carry out two-way pressing according to the conventional pressing process. The height H of the first liner product section 310 is 183.0 mm, and the diameter D of the inner liner parts 311 and 313 is 112.0 mm. Put the sintered graphite boat plate 100 into the boat plate The diameter d of the support section 320 is 75.0 mm, and the height h is a cylindrical lined graphite core 300 of 7 mm, and then the lined product section 310 is ring-cut, and the uncut parts at both ends, that is, the length of the inner liner 311, 313 is 20mm, the depth S of the groove is 1.5mm. A through hole with a diameter d1 of 75.5 mm is opened on the sintered graphite boat plate 100 , that is, the graphi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com