Paste composition, and sintered body and method for producing same

A technology of composition and paste, which is applied to the device for coating liquid on the surface, conductive materials dispersed in non-conductive inorganic materials, coatings, etc., can solve problems such as poor firing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

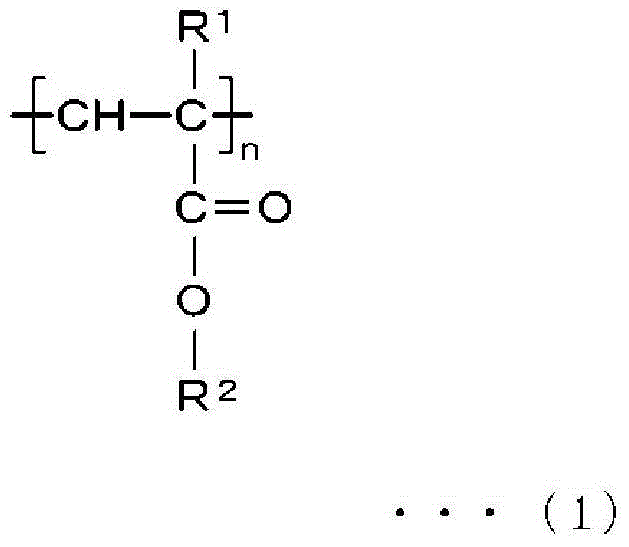

[0132] 4.1.1. Production Example 1 (Preparation of Polymer 1)

[0133] Using the monomer components having the compositions shown in Table 1, a (meth)acrylic (co)polymer, ie, Polymer 1, was prepared by the following method. First, 100 parts by weight of methyl ethyl ketone (MEK) was put into a flask equipped with a stirring device, a nitrogen gas introduction tube, a thermometer, and a reflux cooling tube, and the flask was stirred for 30 minutes while introducing nitrogen gas into the flask to perform nitrogen substitution. The temperature was raised to 80°C. Next, 100 parts by weight of 2-hydroxyisobutyl methacrylate (2HBMA) was added dropwise over 2 hours while maintaining the contents in the flask at 80°C, and azobisisobutyronitrile was added dropwise at the same time as the dropwise addition was started. (AIBN) 0.4 weight part was added 5 times every 1 hour. After 8 hours from the start of dropwise addition, it was cooled to room temperature. The obtained polymer solut...

manufacture example 2

[0134] 4.1.2. Production Example 2 (Preparation of Polymer 2)

[0135] The same method as in the above-mentioned production example was adopted, except that 100 parts by weight of 2HBMA used in the above production example 1 was changed to 30 parts by weight of isobornyl methacrylate (IBXMA), 65 parts by weight of 2HBMA and 5 parts by weight of methacrylic acid (MAA). 1 Polymer 2 was prepared by the same operation. The weight average molecular weight of the obtained polymer 2 was 50,000, the proportion of the structural unit (A) was 68 mol%, the proportion of the structural unit (B) was 22 mol%, the proportion of the structural unit (C) was 10 mol%, and the SP The value was calculated as 9.1.

manufacture example 3

[0136] 4.1.3. Production Example 3 (Preparation of Polymer 3)

[0137] The same procedure as in the above-mentioned Production Example 1 was adopted, except that 100 parts by weight of 2HBMA used in the above-mentioned Production Example 1 was changed to 50 parts by weight of cyclohexyl methacrylate (CHMA) and 50 parts by weight of cyclohexyl dimethanol monoacrylate (CHDMMA). Polymer 3 was prepared by the same operation. The weight average molecular weight of the obtained polymer 3 was 50,000, the ratio of the structural unit (A) was 46 mol%, the ratio of the structural unit (B) was 54 mol%, and the SP value was calculated as 8.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com