A kind of preparation method of spherical lithium ion battery negative electrode material vanadium borate

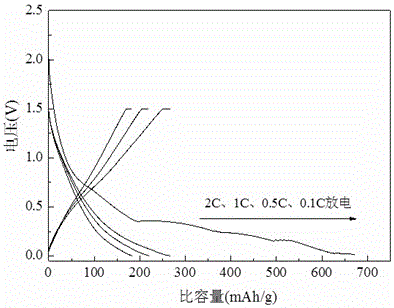

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as low theoretical capacity and poor safety performance, and achieve improved tap density, favorable processing, and excellent electrochemical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment includes the following steps:

[0022] (1) Weigh 0.0125mol of vanadium pentoxide, 0.025mol of boric acid, and 0.05mol of oxalic acid, mix them, and dissolve them in 250mL of deionized water to obtain a mixed solution;

[0023] (2) Place the mixed solution obtained in step (1) in a constant temperature water bath at 60°C and stir for 8 hours to form a solution;

[0024] (3) adjusting the pH value of the solution obtained in step (2) to 7;

[0025] (4) The solution processed in step (3) is dried and granulated by spray drying. The temperature of the spray drying air inlet is 260°C, the rotating speed of the peristaltic pump is 1000 rev / min, and the fan power is 60Hz to obtain vanadium borate (VBO 3 )Precursor;

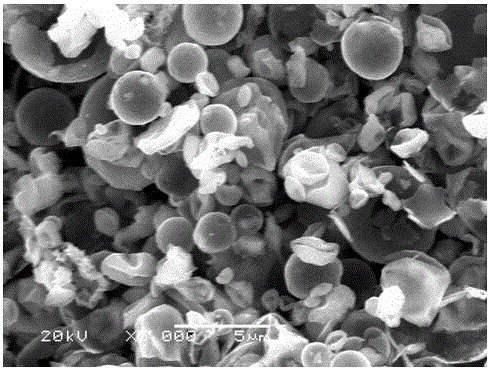

[0026] (5) the vanadium borate (VBO) obtained in step (4) 3 ) precursor was placed in a tubular sintering furnace, sintered at 700 °C for 8 h in an argon atmosphere, and then cooled naturally to room temperature to obtain a spherical lithium-ion...

Embodiment 2

[0030] This embodiment includes the following steps:

[0031] (1) Weigh 0.01mol of ammonium metavanadate, 0.005mol of diboron trioxide, and 0.04mol of citric acid, mix them, and dissolve them in 200mL of deionized water to obtain a mixed solution;

[0032] (2) Place the mixed solution obtained in step (1) in a constant temperature water bath at 90°C and stir for 4 hours to form a homogeneous solution;

[0033] (3) adjusting the pH value of the solution obtained in step (2) to 6;

[0034] (4) The solution processed in step (3) is dried and granulated by spray drying. The temperature of the spray drying air inlet is 180° C., the rotating speed of the peristaltic pump is 1800 rpm, and the fan power is 80 Hz to obtain vanadium borate (VBO 3 )Precursor;

[0035] (5) the vanadium borate (VBO) obtained in step (4) 3 ) precursor was placed in a tubular sintering furnace, sintered at 800 °C for 8 h in an argon atmosphere, and then cooled naturally to room temperature to obtain a sph...

Embodiment 3

[0038] This embodiment includes the following steps:

[0039] (1) Weigh 0.04mol of vanadium pentoxide, 0.08mol of ammonium borate, and 0.18mol of oxalic acid, mix them, and dissolve them in 100mL of deionized water to obtain a mixed solution;

[0040] (2) Place the mixed solution obtained in step (1) in a constant temperature water bath at 80°C and stir for 6 hours to form a homogeneous solution;

[0041] (3) adjusting the pH value of the solution obtained in step (2) to 9;

[0042] (4) carry out dry granulation by the solution that step (3) handles by the method for spray drying, the air inlet temperature of spray drying is 200 ℃, and the peristaltic pump rotating speed is 1500 rev / min, and fan power is 100Hz, obtains vanadium borate ( VBO 3 )Precursor;

[0043] (5) the vanadium borate (VBO) obtained in step (4) 3 ) precursor was placed in a tube-type sintering furnace, sintered at 500 °C for 20 h under a nitrogen atmosphere, and then naturally cooled to room temperature to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com