Detection method of pyrolysis-coking behavior of coal and apparatus therewith

A detection method and coke-forming technology, which is applied in measuring devices, material thermal analysis, instruments, etc., can solve the problems of incomplete measurement conditions, strong experience requirements, and few detection indicators, and achieve comprehensive detection effects, simple operation methods, The effect of detecting multiple indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

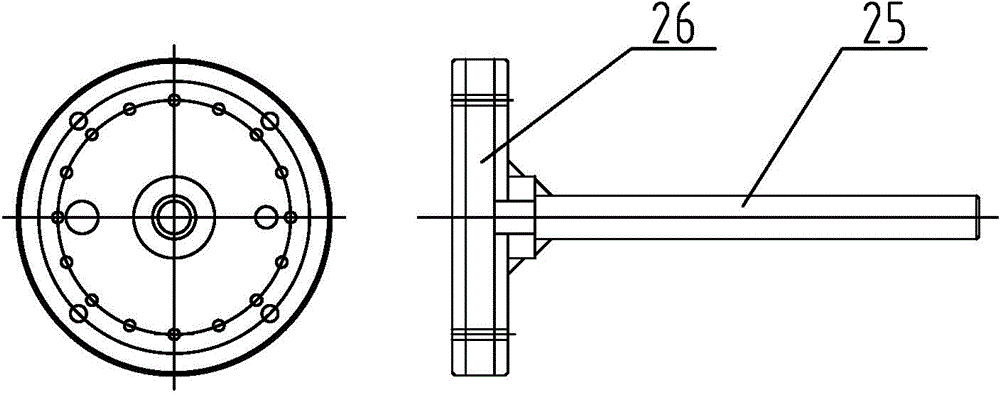

Image

Examples

Embodiment Construction

[0045] The present invention will be described in more detail below in conjunction with the accompanying drawings.

[0046] Such as figure 1 As shown, a coal pyrolysis-coking behavior detection method, the method is as follows:

[0047] 1. Select and install the detection device

[0048] Using precision electronic balance 2 for weighing, the measuring range is 10kg, and the sensing capacity is 0.10g; the electric furnace is used as the heating furnace, the furnace body 5 is an all-stainless steel shell structure, and the integral furnace lining is adopted. The overall size of the furnace body 5 is Φ240mm×205mm, and the furnace size is Φ65mm×160mm , the heating element is an infrared carbon fiber heater (28), the maximum electric power is 2KW, the maximum temperature of the heating furnace is 1100°C, the body of furnace 5 is supported by a support, and the bottom of the furnace is about 2cm high from the electronic balance 2; the temperature is measured by a K-type armored the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com