SiO2-TiO2 inorganic hybrid thermosetting thermosetting phenolic resin and preparation method thereof

A phenolic resin and thermosetting technology, which is applied in the field of SiO2-TiO2 inorganic hybrid thermosetting phenolic resin and its preparation, can solve the problems of nanoparticle agglomeration, poor dispersion, inorganic particle dispersion, etc., achieve good dispersion and improve heat resistance , Improving the effect of impact performance and tensile performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

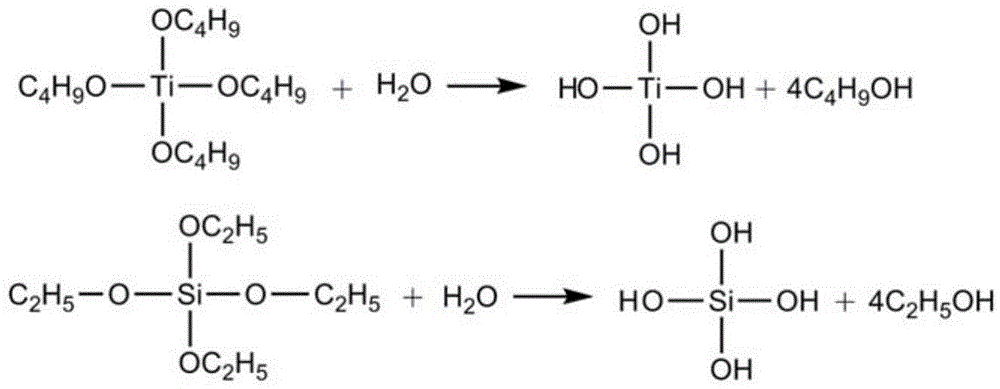

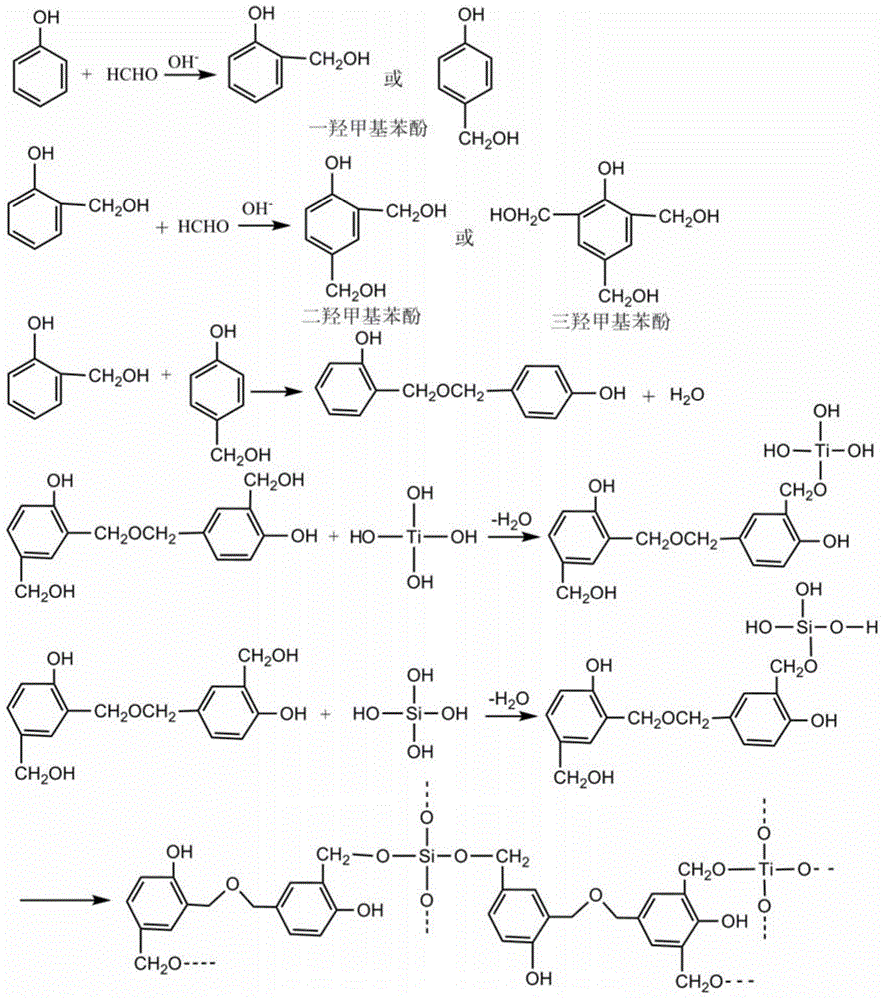

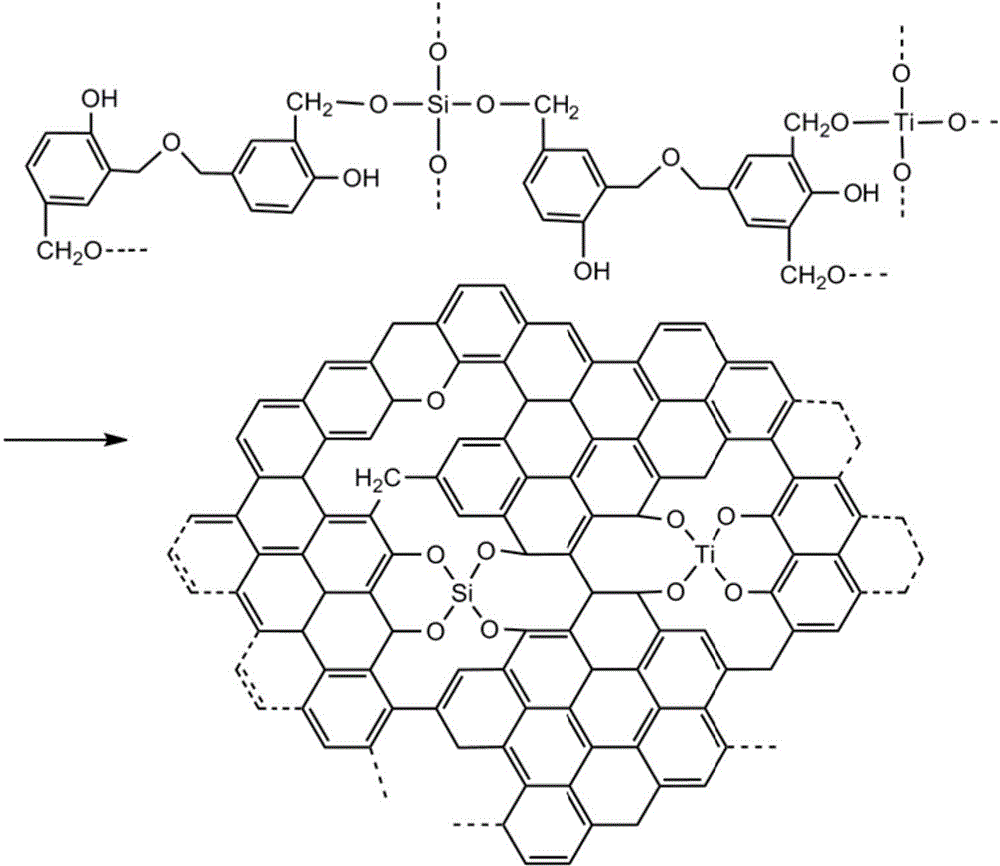

[0036] SiO of the present invention 2 -TiO 2 The preparation method of inorganic hybrid thermosetting phenolic resin comprises the steps:

[0037] (1) Dissolve 100 to 200 parts of phenol in 85 to 175 parts of formaldehyde solution according to the ratio of parts by mass, and add 0.2 to 8 parts of ethyl orthosilicate, 0.2 to 8 parts of tetrabutyl titanate in sequence, and 40 to 8 parts of tetrabutyl titanate Stir in a water bath at 50°C for 10 to 30 minutes, then add barium hydroxide octahydrate to adjust the pH of the solution to 8 to 9, slowly raise the temperature to 60 to 70°C, and perform a constant temperature reaction for 1 to 3 hours; the heating rate is 0.16 to 0.33°C / min;

[0038] (2) Slowly raise the temperature of the solution obtained in step (1) from 60 to 70°C to 85 to 98°C, carry out a constant temperature reaction for 1 to 3 hours, and the heating rate is 0.16 to 0.33°C / min;

[0039] (3), add phosphoric acid solution, adjust the pH value of the solution obtai...

Embodiment 1

[0043] According to parts by mass, dissolve 130 parts of phenol in 140 parts of formaldehyde solution, add 4 parts of ethyl orthosilicate and 4 parts of tetrabutyl titanate in sequence, stir in a water bath at 40°C for 30 minutes, and then add 1.1 parts of barium hydroxide octahydrate Adjust the pH value of the solution to 8-9, slowly raise the temperature to 60° C., and carry out constant temperature reaction for 1-3 hours; the heating rate is 0.25° C. / min; the mass concentration of the formaldehyde solution is 37%.

[0044] Slowly raise the temperature of the above solution from 60°C to 95°C, carry out constant temperature reaction for 1 hour, and the heating rate is 0.25°C / min;

[0045] Add 1.3 parts of phosphoric acid solution, adjust the pH value of the above solution to 5-6, stir for 15 minutes, and dehydrate in a water bath at 95°C under vacuum for 1 hour, let stand, precipitate, filter, cool to room temperature, and take out the upper layer of pure resin, that is Get S...

Embodiment 2

[0052] According to parts by mass, dissolve 100 parts of phenol in 85 parts of formaldehyde solution, and then add 0.2 parts of ethyl orthosilicate and 0.2 parts of tetrabutyl titanate in sequence, stir in a water bath at 40°C for 30 minutes, and then add 0.3 parts of barium hydroxide octahydrate Adjust the pH value of the solution to 8-9, slowly raise the temperature to 60° C., and carry out constant temperature reaction for 1-3 hours; the heating rate is 0.16° C. / min; the mass concentration of the formaldehyde solution is 35%.

[0053] Slowly raise the temperature of the above solution from 60°C to 95°C, carry out constant temperature reaction for 1 hour, and the heating rate is 0.16°C / min;

[0054] Add 0.5 parts of phosphoric acid solution, adjust the pH value of the above solution to 5-6, stir for 15 minutes, and dehydrate in a water bath at 95°C under vacuum for 3 hours, let stand, precipitate, filter, cool to room temperature, and take out the upper layer of pure resin, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotational viscosity | aaaaa | aaaaa |

| Rotational viscosity | aaaaa | aaaaa |

| Rotational viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com