Silicon-containing diphenol and preparation method thereof

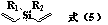

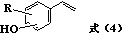

A technology of dihydric phenol and silane, which is applied in the field of silicon-containing dihydric phenol as a monomer of organosilicon materials and its preparation, can solve and/or solve the problems of cumbersome synthesis methods, difficulty in large-scale production, and poor performance, and achieve the goal of preparing Derivatives are convenient, high in industrial production value, and low in cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

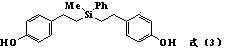

[0032] The synthesis of embodiment 1 methylphenyl bis (4-hydroxy styryl) silane

[0033] Under the protection of nitrogen, the 80mL methylene chloride solution of 17.4g (0.10mol) of methylphenyldivinylsilane and 30.0g (0.25mol) of 4-vinylphenol was heated to 40°C for 15min, and 3.2g of ruthenium catalyst Cat- 1. Continue the heat preservation reaction for 8 hours, evaporate the solvent, and recrystallize the residue with ethyl acetate to obtain 33.1 g of off-white solid product methylphenylbis(4-hydroxystyryl)silane, with a yield of 92.5% and a content of 97.7% . MS (m / z): 359 [M+H] + .

Embodiment 2

[0034] Example 2 Synthesis of dimethylbis (3-hydroxyl-4-methoxystyryl) silane

[0035] Under nitrogen protection, heat a solution of 11.2g (0.10mol) of dimethyldivinylsilane and 34.5g (0.23mol) of 2-methoxy-5-vinylphenol in 80mL of dichloromethane to 30°C for 10min, and add 2.8 g ruthenium catalyst Cat-2, stirred at room temperature for 12 hours, evaporated the solvent, and recrystallized the residue from butyl acetate to obtain off-white solid product dimethylbis(3-hydroxy-4-methoxystyryl)silane 32.7 g, yield 91.8%, content 98.2%. MS (m / z): 357 [M+H] + .

Embodiment 3

[0036] Example 3 Synthesis of diphenylbis(3-methyl-4-hydroxystyryl)silane

[0037] Under nitrogen protection, heat a solution of 23.6g (0.10mol) of diphenyldivinylsilane and 34.8g (0.26mol) of 2-methyl-4-vinylphenol in 80mL of dichloromethane to 40°C for 10min, and add 2.5g Ruthenium catalyst Cat-3, continued insulation reaction for 14h, evaporated the solvent, and the residue was recrystallized with ethyl lactate to obtain 42.0 g of off-white solid product diphenylbis(3-methyl-4-hydroxystyryl)silane, Yield 93.7%, content 98.4%. MS (m / z): 449 [M+H] + .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com