Machining device of large-capacity circuit breaker contact system

A contact system and processing device technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low work efficiency and unreliable product quality, and achieve stable welding quality, continuous and efficient operation, and large area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

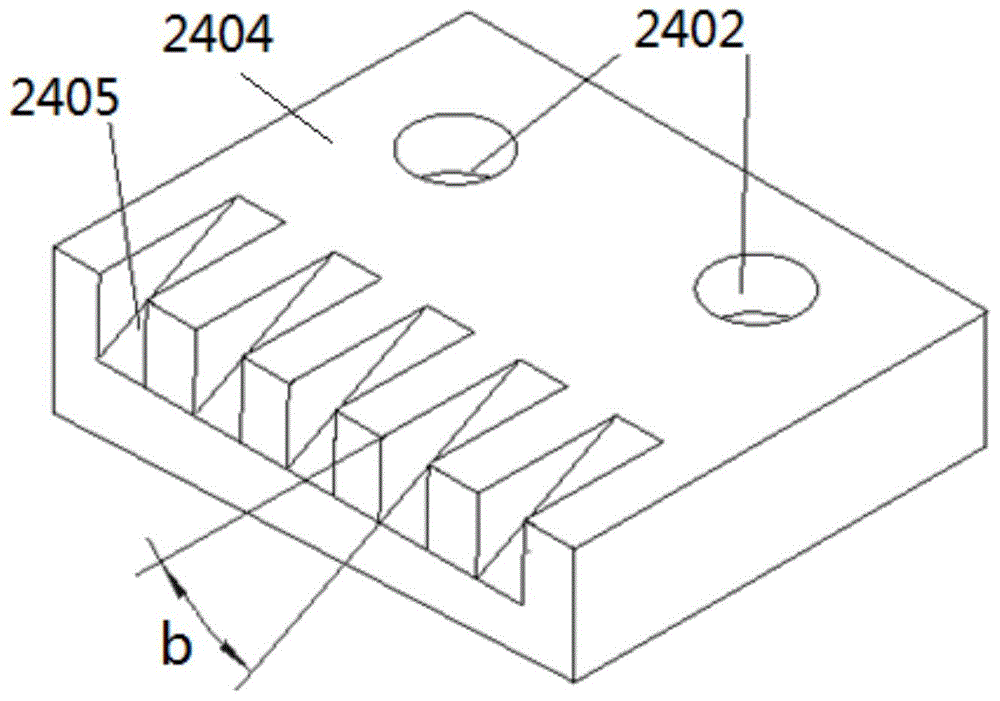

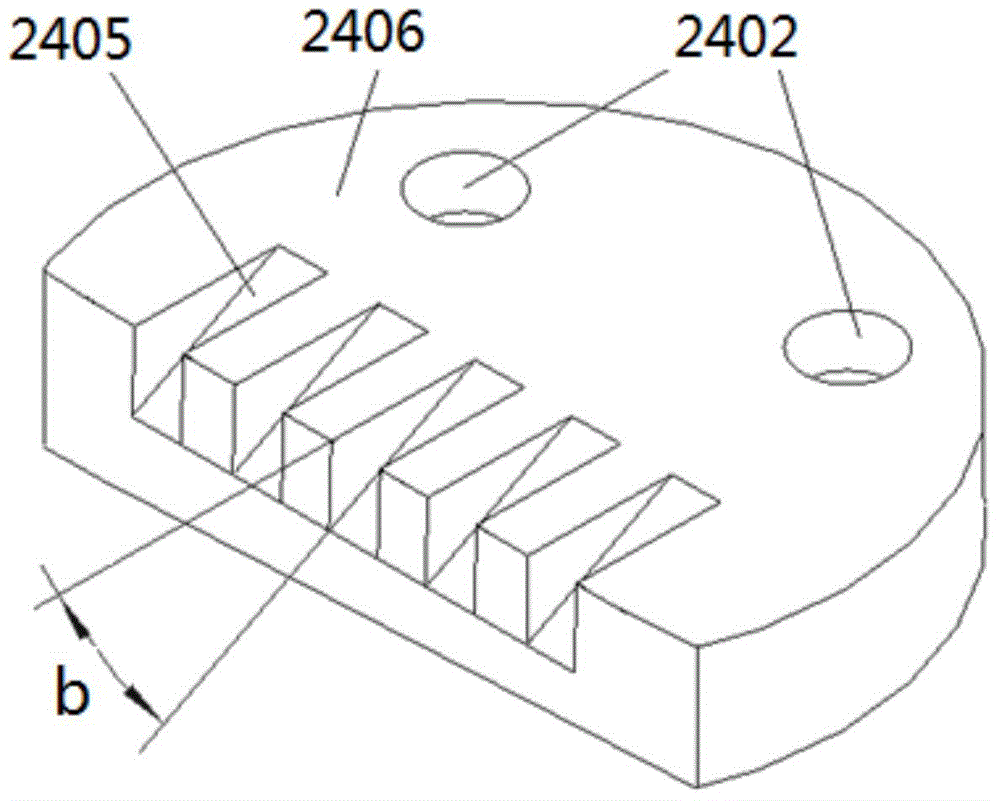

[0061] Embodiment 1 is that a plurality of inclined plane U-shaped grooves 2405 (or multiple U-shaped grooves) equidistant are provided at the front end of the rectangular plate 2404, and the angle b between the inclined plane of each inclined plane U-shaped groove 2405 and the upper surface of the rectangular plate 2404 is 15°-20°, there is at least one counterbore 2402 for fixing on the rear body of the rectangular plate 2404, and the rectangular plate 2404 can also be set as a square plate or other shapes, such as the semicircular arc plate 2406 of embodiment 2, implementing The rounded rectangular plate 2407 of Example 3 (a confluence of square and arc shapes). The busbar 24 of these three embodiments cooperates with the fixture 100 through at least one cylinder (passed in the counterbore 2402) to form a fixture that can be positioned, clamped and clamped at one time, and the rectangular plate 2404 and the soft connection and the moving contact are clamped and welded Conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com